ChipMeister

Plastic

- Joined

- Jul 14, 2016

Greetings! I see I'm in good company here- lots of enthusiasts at all levels. Myself, until just recently I last used a lathe back in 1983. So, yeah, it's been a while.

Anyway, I have this lathe, a model A, catalog #CL8145C, serial #3008TKL10. Got it with a bunch of tools and accessories and it appears in fair condition. I've been incrementally cleaning it to ensure I'm not only familiar with it but that all the controls and positions are at least nominal. I've been creating a pile of chips and ribbons and that's about as much expertise as I've ever had on a lathe. So far, so good.

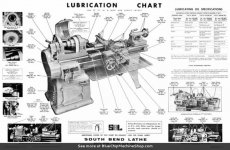

I also obtained the recommended SBL lubricants and using the lubrication chart for this lathe I ensured all oil pots and points were adequately addressed.

So here's my problem...

Until yesterday everything worked as expected. Now the lead screw reversing gears are bound up and upon disassembly I found that one of the two smaller gears has some scoring on the inside diameter; the shaft looks pretty good, though. Curious is the absence of any bushing, bronze or otherwise. The shaft and gear still slide intimately together, with no obvious play, but it is a steel-on-steel configuration.

So my first question is, shouldn't there be a bushing pressed into the gear? On this item there is zero room for a bushing.

My second question is, where does one purchase the wicks that ultimately will be installed in this gear system? I've read that there are differing shapes and sizes unique to installation position on the lathe.

Opinions of those smarter and/or more experienced than me are most welcome!

Thanks!

Anyway, I have this lathe, a model A, catalog #CL8145C, serial #3008TKL10. Got it with a bunch of tools and accessories and it appears in fair condition. I've been incrementally cleaning it to ensure I'm not only familiar with it but that all the controls and positions are at least nominal. I've been creating a pile of chips and ribbons and that's about as much expertise as I've ever had on a lathe. So far, so good.

I also obtained the recommended SBL lubricants and using the lubrication chart for this lathe I ensured all oil pots and points were adequately addressed.

So here's my problem...

Until yesterday everything worked as expected. Now the lead screw reversing gears are bound up and upon disassembly I found that one of the two smaller gears has some scoring on the inside diameter; the shaft looks pretty good, though. Curious is the absence of any bushing, bronze or otherwise. The shaft and gear still slide intimately together, with no obvious play, but it is a steel-on-steel configuration.

So my first question is, shouldn't there be a bushing pressed into the gear? On this item there is zero room for a bushing.

My second question is, where does one purchase the wicks that ultimately will be installed in this gear system? I've read that there are differing shapes and sizes unique to installation position on the lathe.

Opinions of those smarter and/or more experienced than me are most welcome!

Thanks!

Attachments

Last edited: