Jim in Wis.

Plastic

- Joined

- Jan 12, 2011

- Location

- Sheboygan Falls, Wis

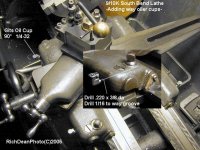

My 1946 9A is missing a few oil hole covers. The tailstock has two empty 11/64 holes, the bracket on the end of the lead screw has a 1/8 hole, the compound has an empty 9/64 hole, and above the lever for threading there is a 11/64 hole. Are these all supposed to have Gits covers? I looked on the Gits site and they show one straight drive in for a 5/32 hole. I would think the holes would all be the same size if they all had the same type fittings, but they sure don't seem to be. I've seen where some of the older lathes had brass plugs in some places - would mine have had those? Any thoughts on this?

.

.