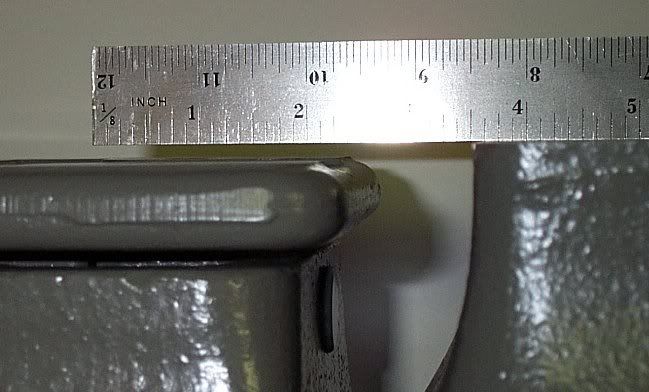

Take a close look between the pedestal foot and the bed casting. See those 1/8" shims in there?

That's not my lathe, but mine had them. I just assumed they had to be the work of the same guy who mispainted this lathe. But then I found that someone else has them!

They're just crudely cut pieces of 1/8" flat bar stock. They have a very homemade look.

I was planning to leave them out, but now I'm not so sure. Seems pretty clear now that SB put them in, so I gotta figure there's a good reason.

Will have to try to take some measurements to see if I can find a reason. Really could use a 5ft surface plate!

My lathe's S/N is one of the ones with an X in it, meaning it's "special". I took that to mean a good thing. Now I'm thinking it's P.C. for "challenged".

Does anyone else know about, or have these plates?

Ken