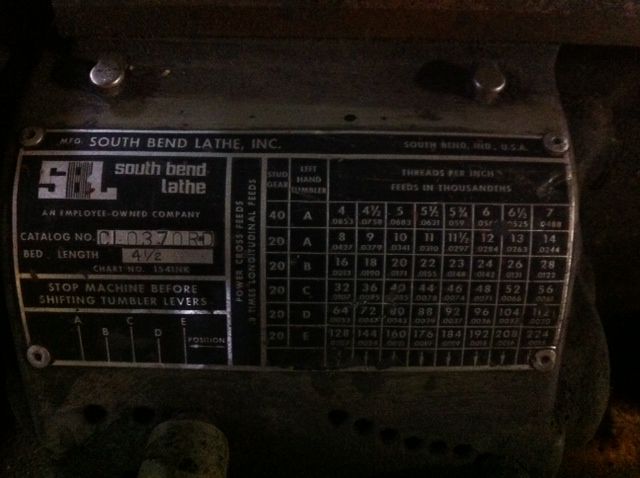

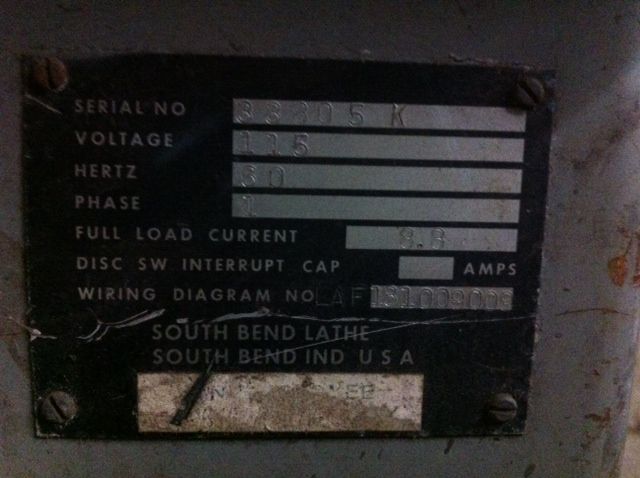

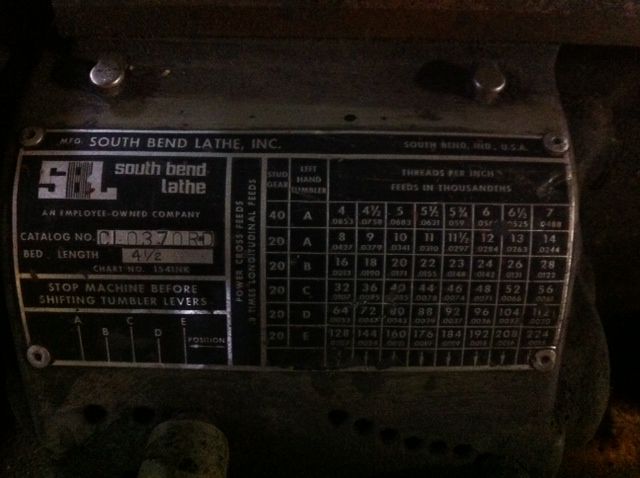

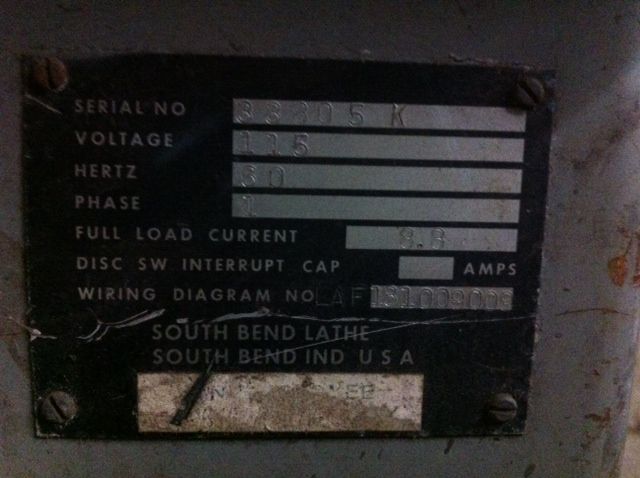

hello all, this is my 1st post. i am new to the machine shop world.i am a standard shift transmission tech by day and welder fabricator by night. i have always had an interest in machine tools such as lathes and milling machines. i have grown up around it and even have a trimester of tech collage machine shop course under my belt. that being said i know very very little. i recently bought a 1976 south bend 10k lathe 4.5' bed, and i plan to restore it.

the ways are pretty rough but everything else can be replaced or cleaned up i believe. i will have pictures of the ways soon to get opinions on if its salvageable or not.

so, the story...

Craigslist buy, the picture displayed the machine indoors with no rust.. needless to say this is how i found it.. out side under a make shift plastic covering...

so the craigs list add posted that it was 500 bucks. i texted the guy (nice guy) and he told me the cross-feed screw was damaged and the electrical forward/reverse switch was busted and that the apron casting was broke. o i wasn't expecting a beauty queen when i showed up. anyway i went low he went high we settled for 400 bucks.

got it back to my shop to find the compound screw was also damaged, the lead screw half nuts (inside the apron) were totally shot.. and while none of the end gears had broken teeth, one of them was very badly worn.. oh, and the tail stock casting is also really worn.. the ways are beat up too.. anyway she is just a broke down lady of the night in need of someone to love her..

here are the rest of the pictures i took today. i started with the disassembly of the apron casting, then the carriage, then the tail stock.

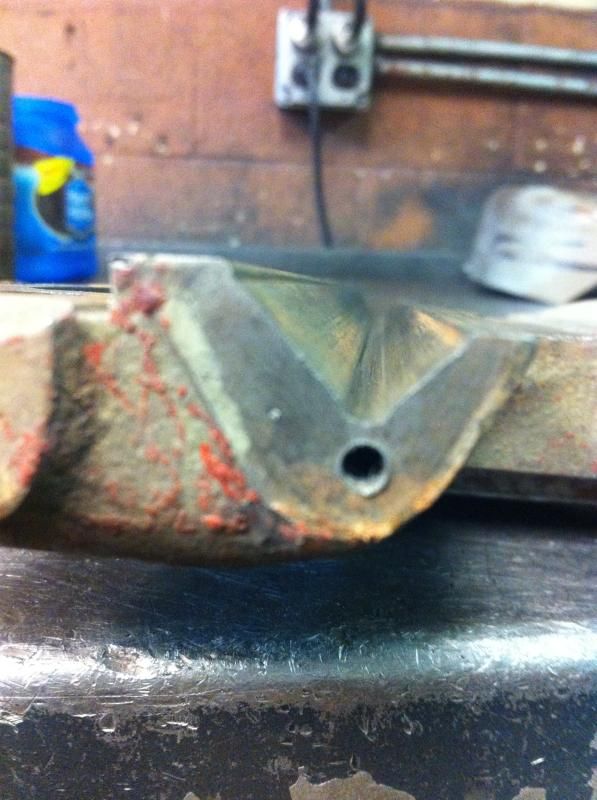

busted casting

worn out half nuts

carriage

disassembled, all the pieces in need of replacement there above the red shop towel.

the tail stock wasn't too bad.. but i assume the bottom casting shouldnt look like this..

everything disassembled

im going to get these 3 components rebuilt then i am going to tackle the rest of the machine.. any advice would be greatly appreciated, hope you guys enjoy the thread.

thanks,

brandon

the ways are pretty rough but everything else can be replaced or cleaned up i believe. i will have pictures of the ways soon to get opinions on if its salvageable or not.

so, the story...

Craigslist buy, the picture displayed the machine indoors with no rust.. needless to say this is how i found it.. out side under a make shift plastic covering...

so the craigs list add posted that it was 500 bucks. i texted the guy (nice guy) and he told me the cross-feed screw was damaged and the electrical forward/reverse switch was busted and that the apron casting was broke. o i wasn't expecting a beauty queen when i showed up. anyway i went low he went high we settled for 400 bucks.

got it back to my shop to find the compound screw was also damaged, the lead screw half nuts (inside the apron) were totally shot.. and while none of the end gears had broken teeth, one of them was very badly worn.. oh, and the tail stock casting is also really worn.. the ways are beat up too.. anyway she is just a broke down lady of the night in need of someone to love her..

here are the rest of the pictures i took today. i started with the disassembly of the apron casting, then the carriage, then the tail stock.

busted casting

worn out half nuts

carriage

disassembled, all the pieces in need of replacement there above the red shop towel.

the tail stock wasn't too bad.. but i assume the bottom casting shouldnt look like this..

everything disassembled

im going to get these 3 components rebuilt then i am going to tackle the rest of the machine.. any advice would be greatly appreciated, hope you guys enjoy the thread.

thanks,

brandon