bradjacob

Titanium

- Joined

- Nov 18, 2008

- Location

- Easton, PA

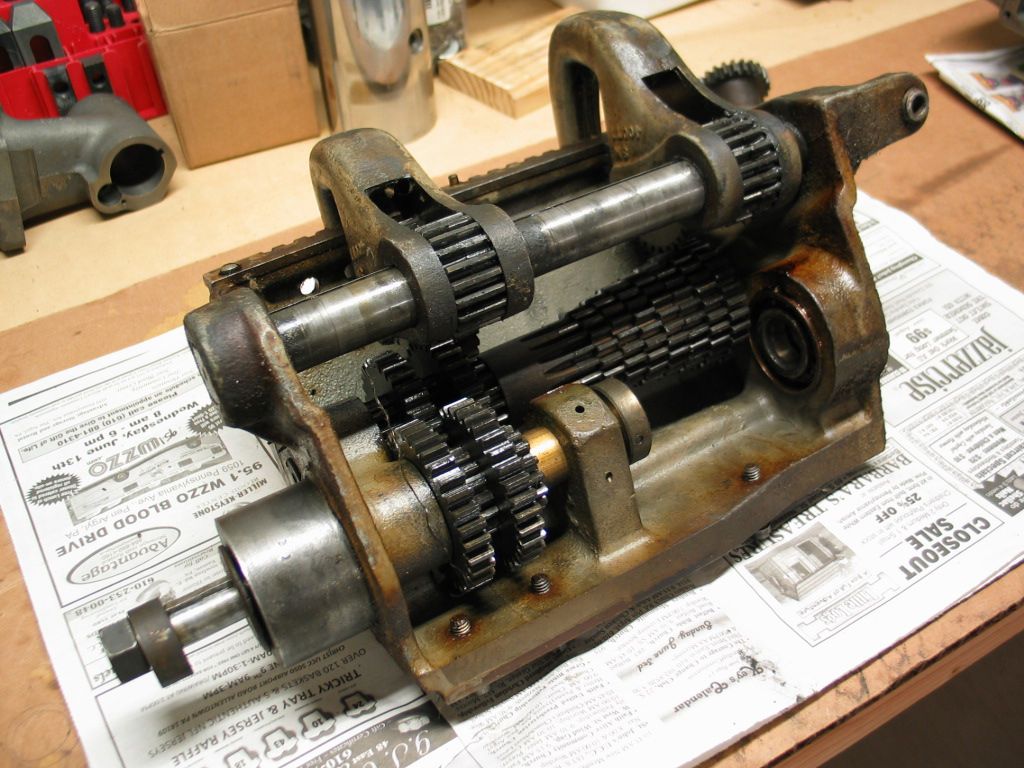

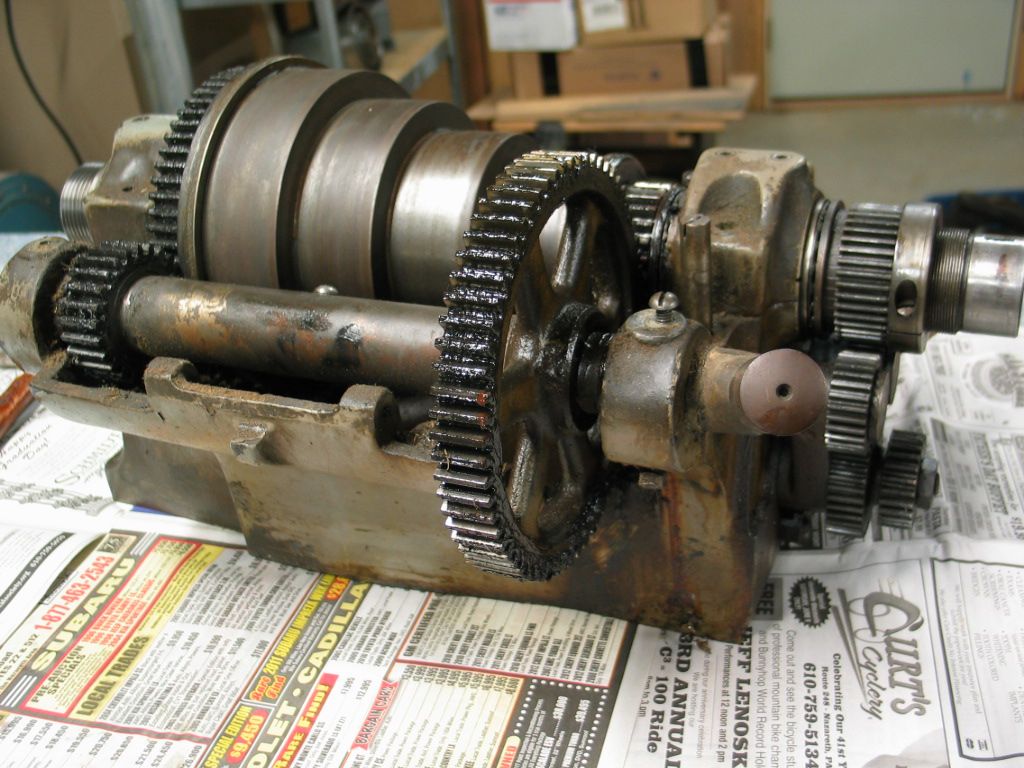

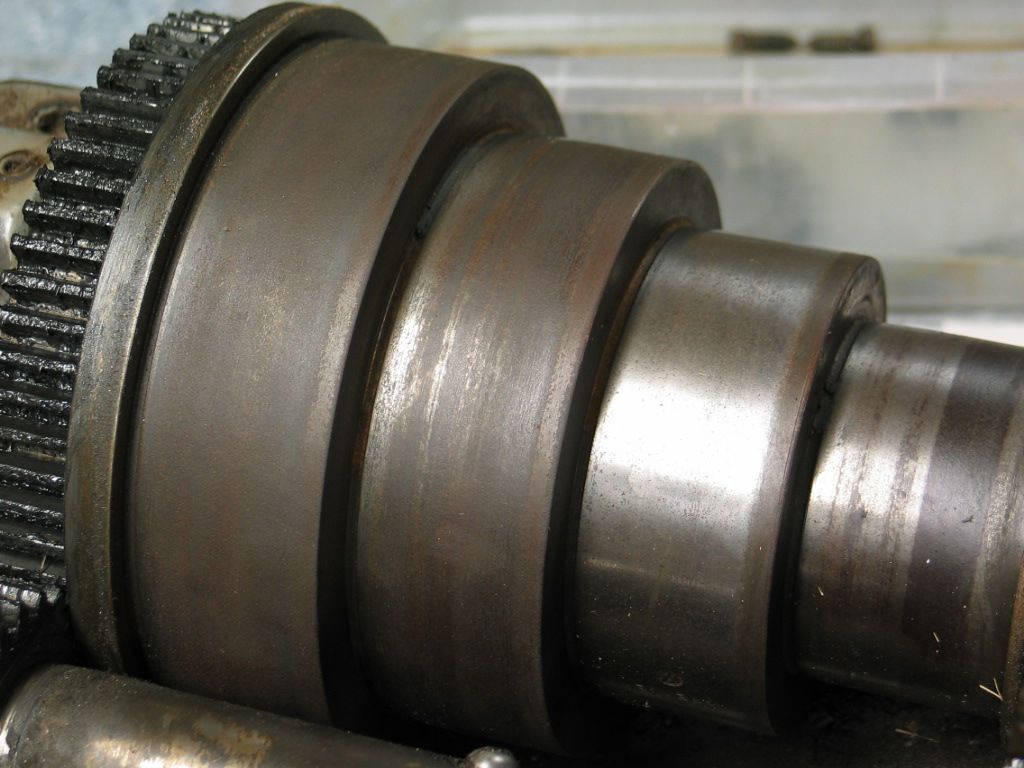

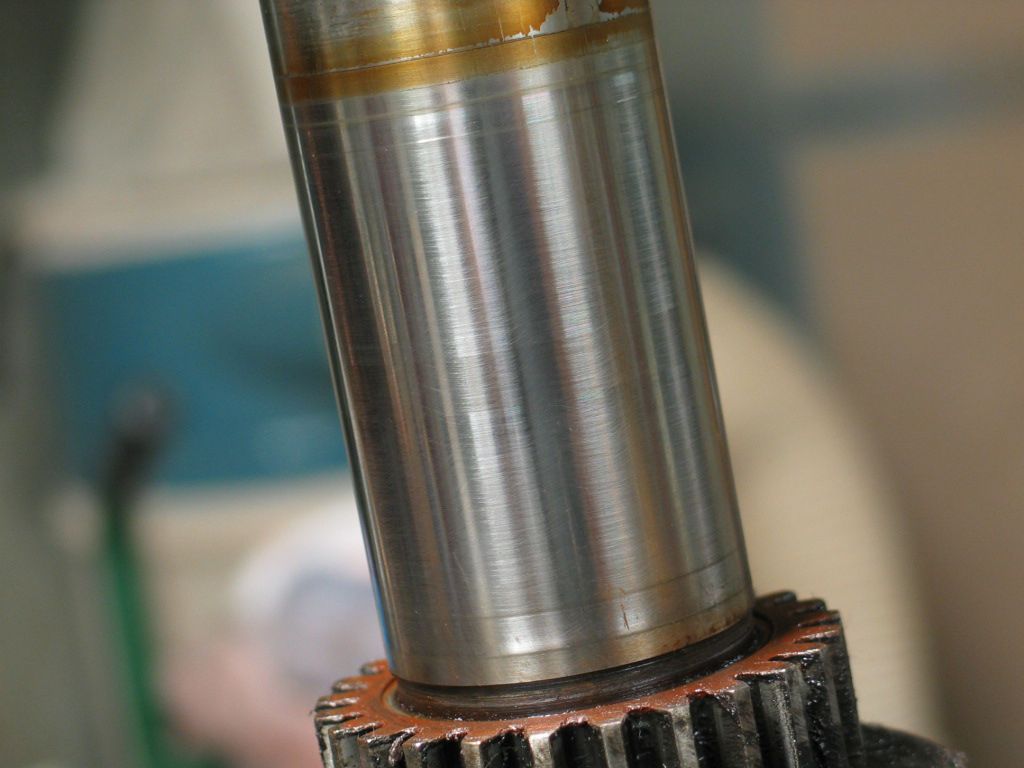

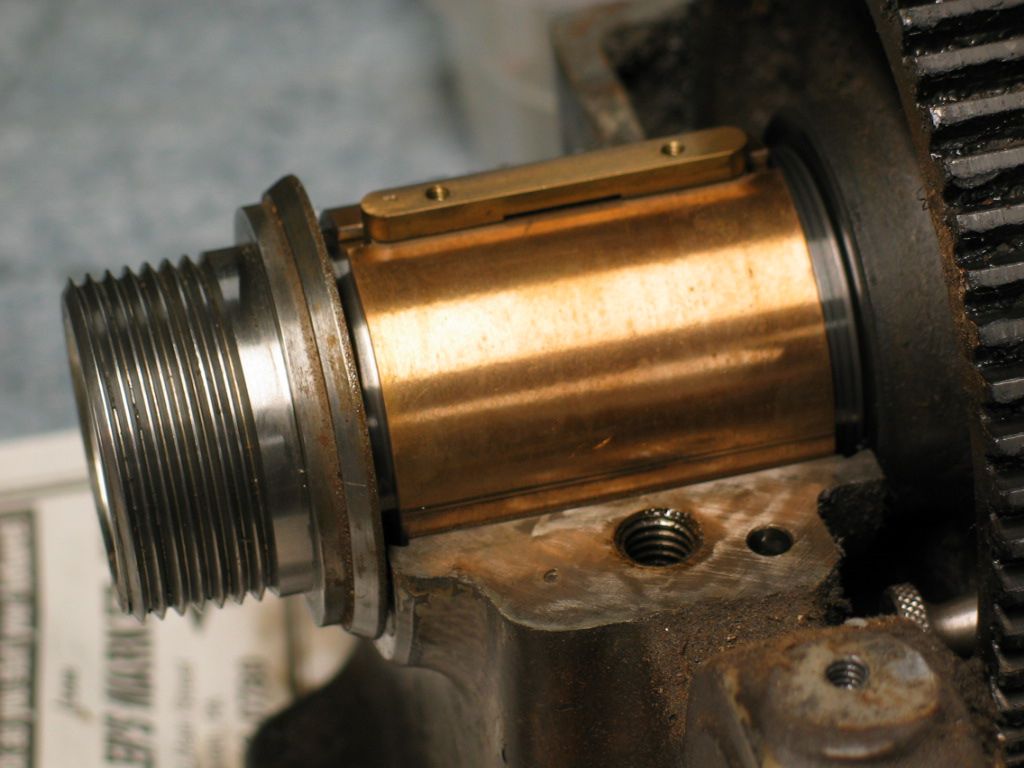

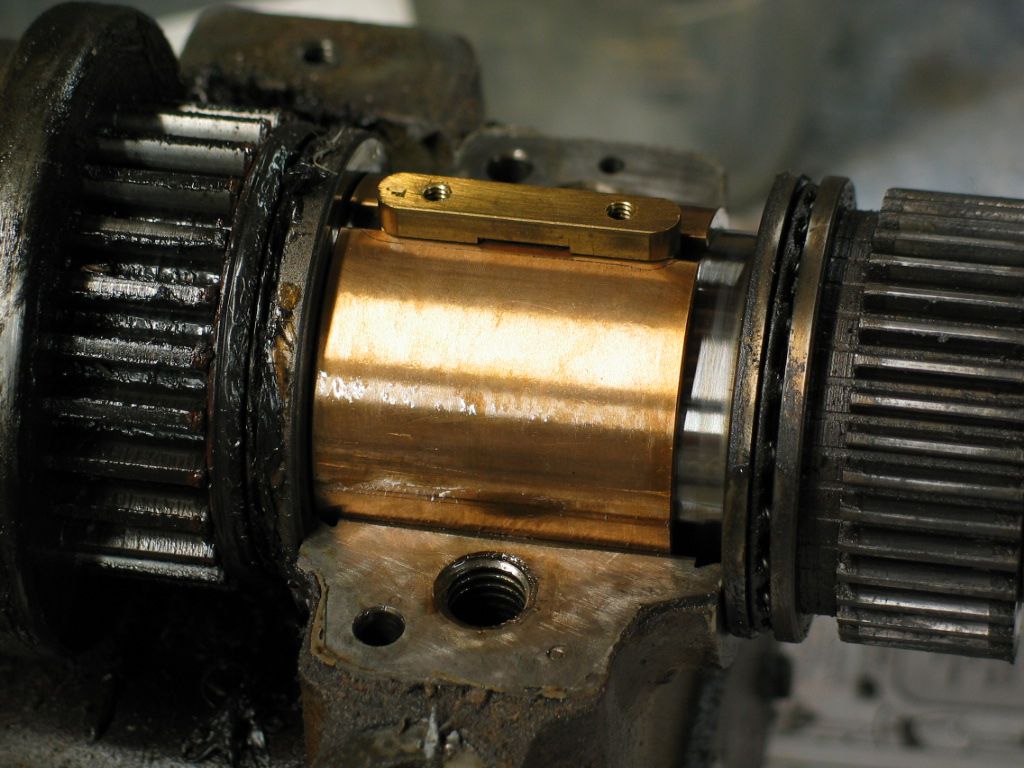

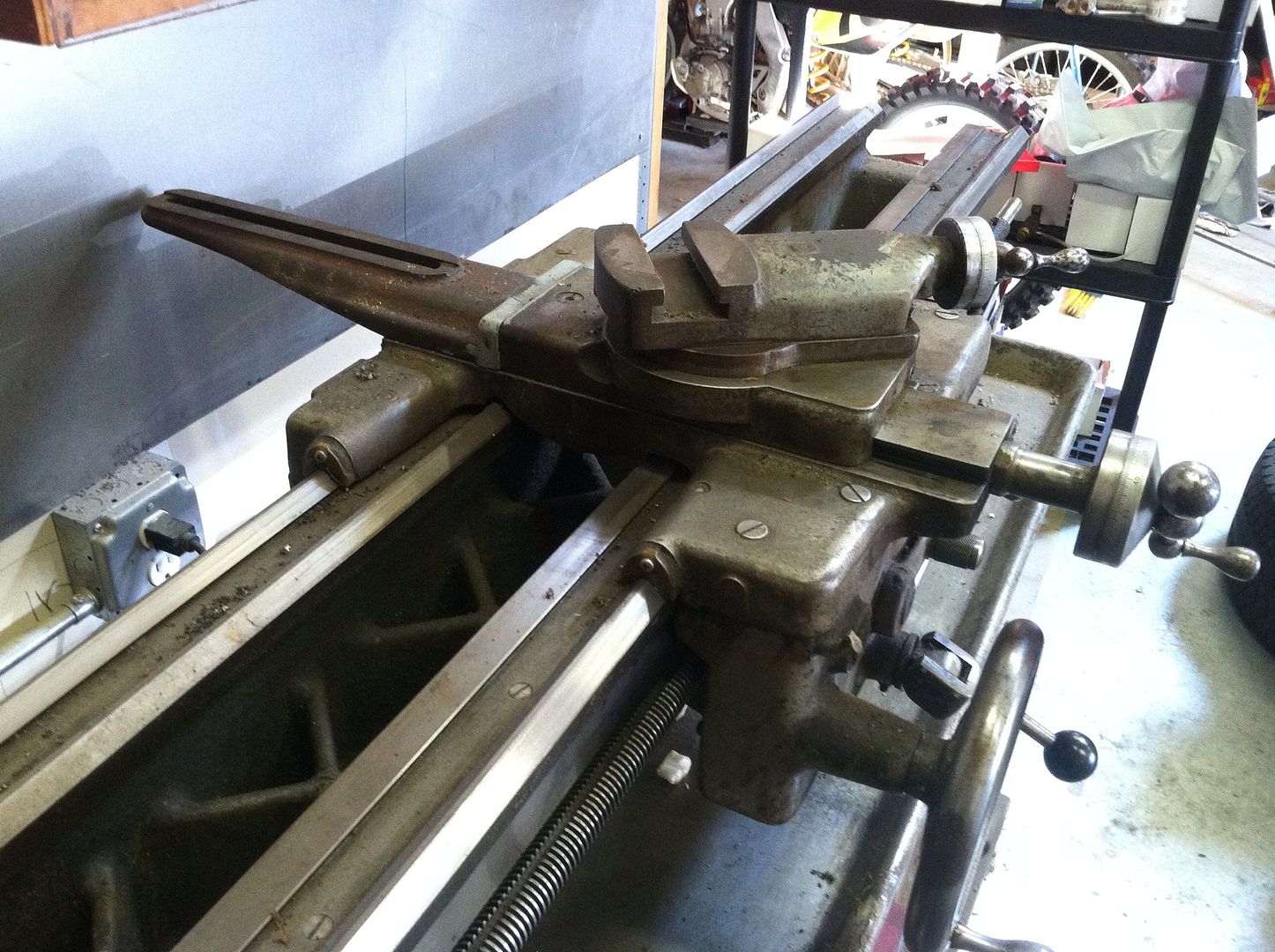

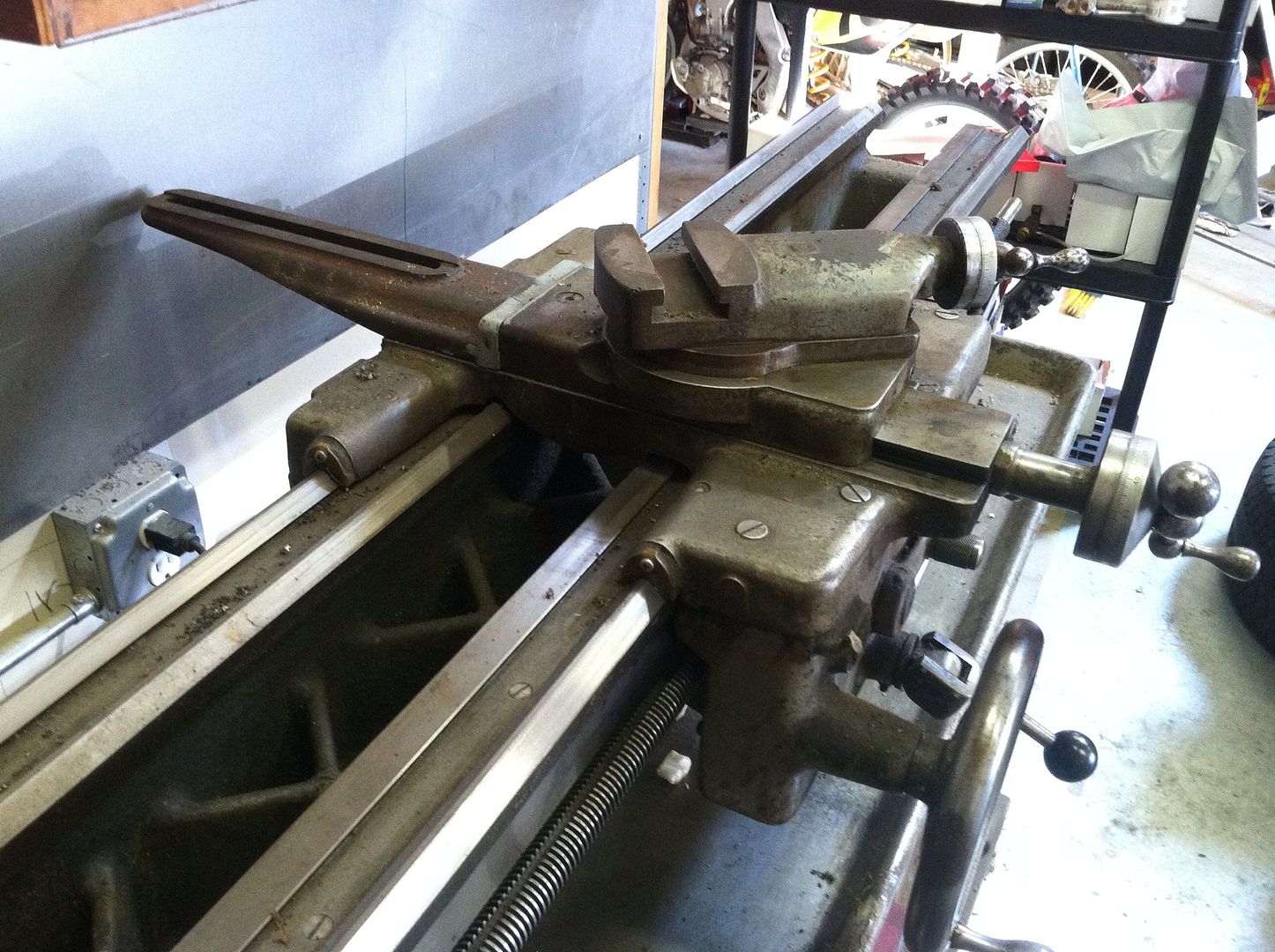

I picked up this 13" today in Bricktown NJ. Upon inspection, I found it to be in mechanically great condition. No visible wear or ridge on the bed. Picking up on the spindle, showed a reading of .001 the test bar showed a reading of about .001 -.002 from half way on the bed, to the headstock.

The inside taper of the spindle was smooth as glass and the tailstock, cross feed and compound dial turned smooth and tight. All gears have good teeth, none broken. When I turned it on, the motor and gear train was surprisingly quiet and smooth. So I think I got me a good one. I'll be taking my time with this one as I'm still finishing up the Bridgeport.

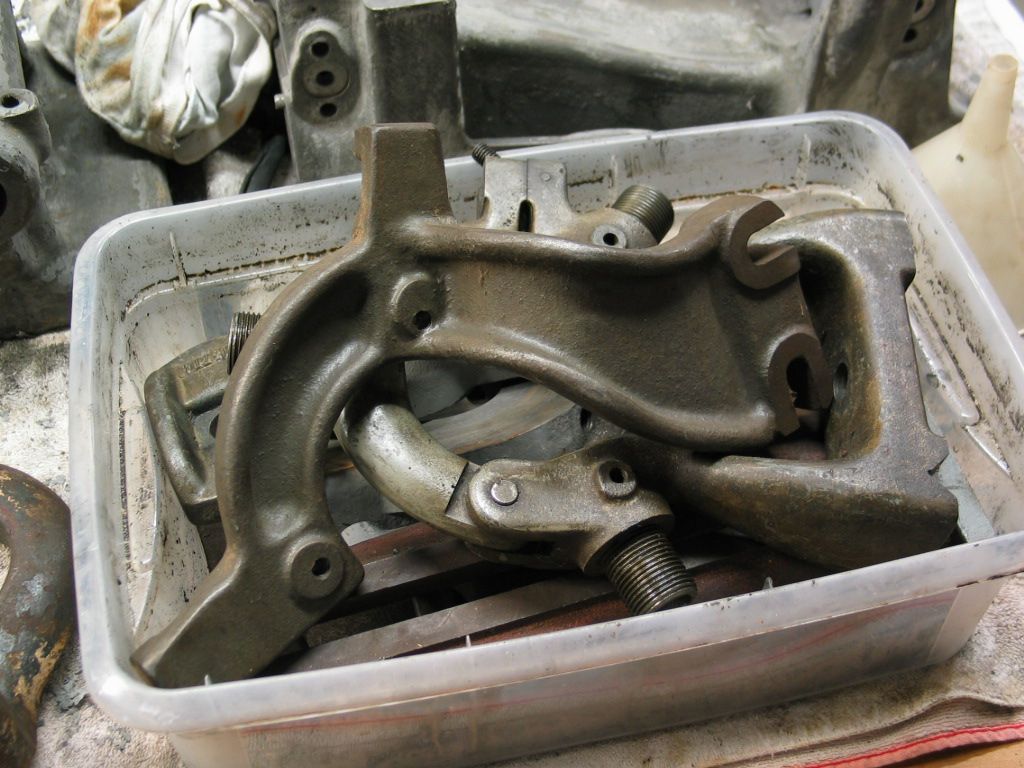

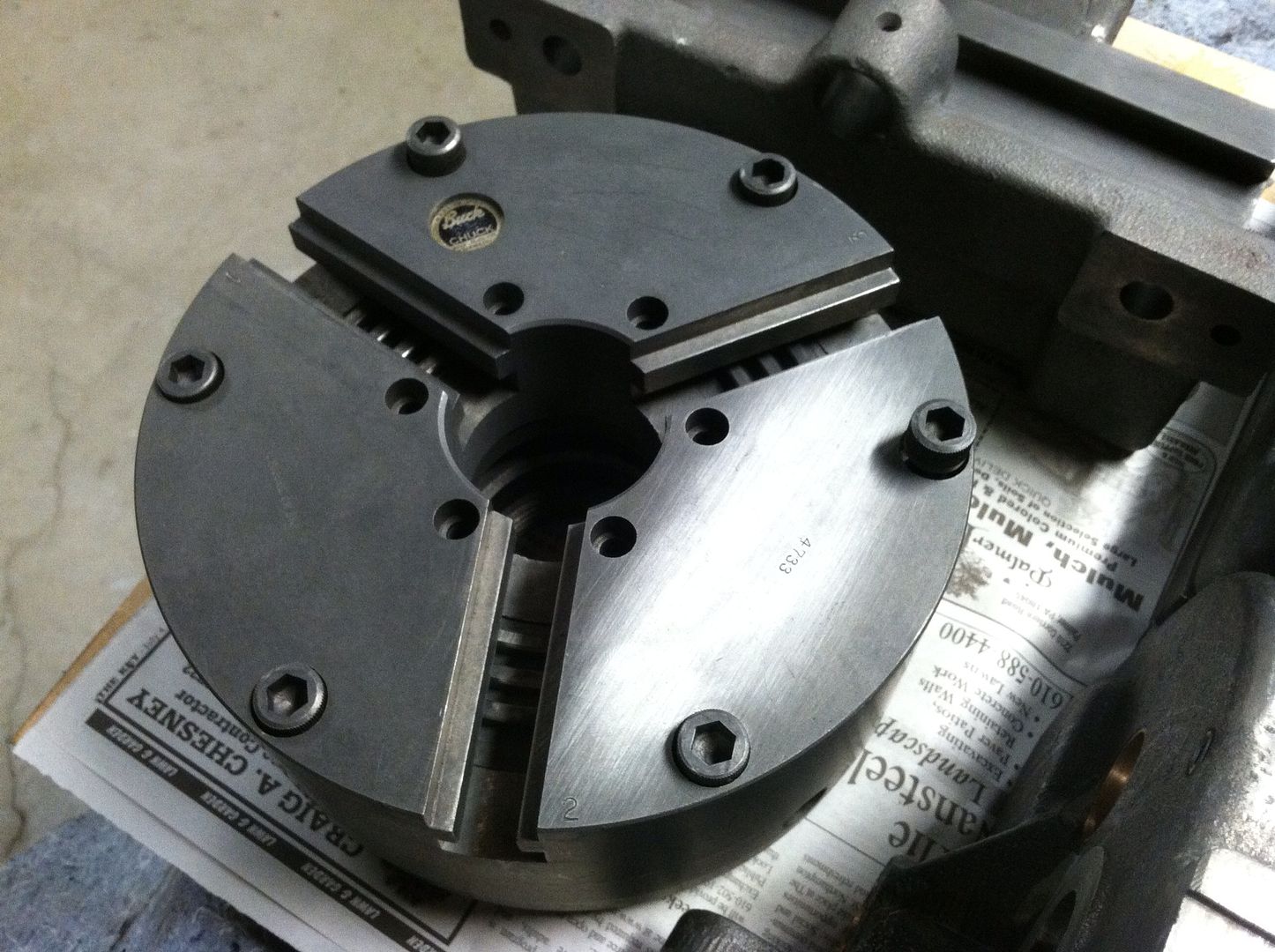

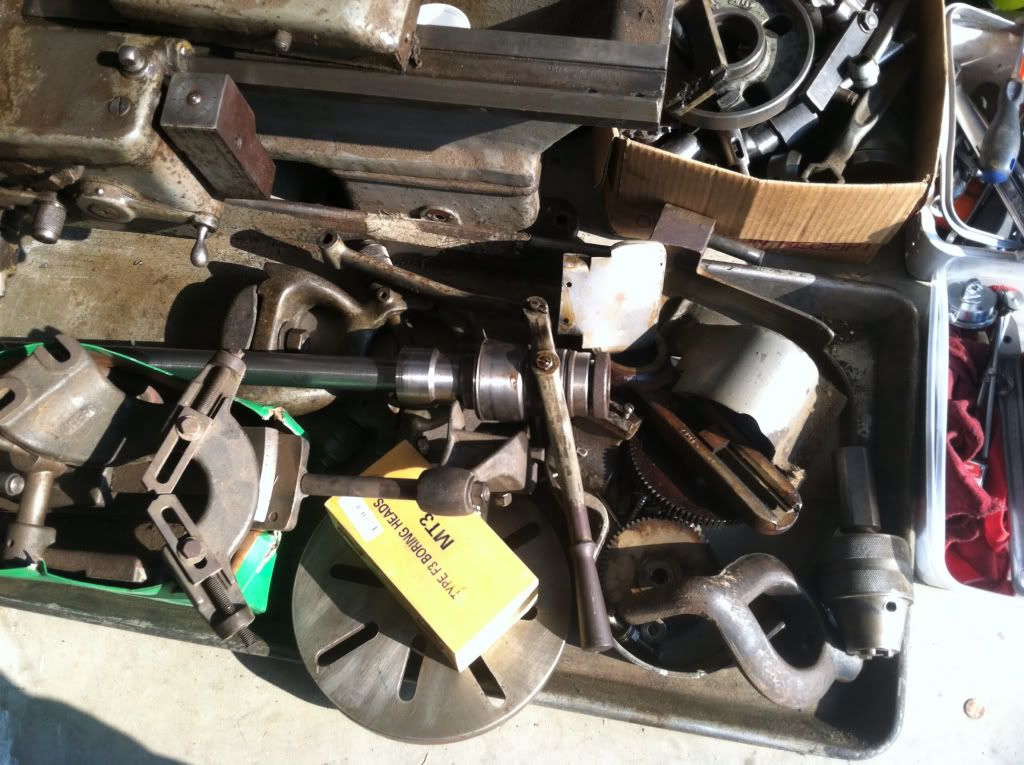

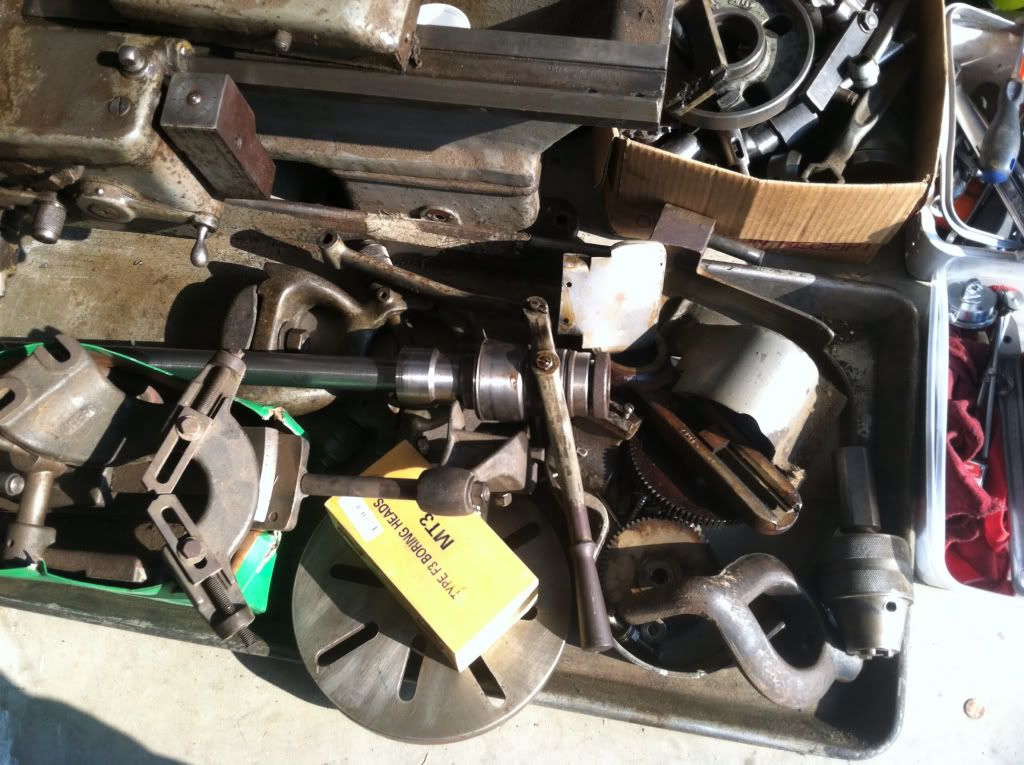

Price was $1,600 for the lathe. Tooling was $1,200 (collet lever, 67 collets, steady, follower, taper, 4-jaw, 3-jaw, Aloris BXA and 6 holders, micrometer stop, threading dial, face plates, dog driver & dogs, turret adapter, taping head, live centers, dead centers, drill chucks, tool bits, collet sleeve and KO nut)

As with my Heavy-10 and 9a, this too will get the full treatment (repaint, rewick and polishing).

Now for some pictures!

The inside taper of the spindle was smooth as glass and the tailstock, cross feed and compound dial turned smooth and tight. All gears have good teeth, none broken. When I turned it on, the motor and gear train was surprisingly quiet and smooth. So I think I got me a good one. I'll be taking my time with this one as I'm still finishing up the Bridgeport.

Price was $1,600 for the lathe. Tooling was $1,200 (collet lever, 67 collets, steady, follower, taper, 4-jaw, 3-jaw, Aloris BXA and 6 holders, micrometer stop, threading dial, face plates, dog driver & dogs, turret adapter, taping head, live centers, dead centers, drill chucks, tool bits, collet sleeve and KO nut)

As with my Heavy-10 and 9a, this too will get the full treatment (repaint, rewick and polishing).

Now for some pictures!

I did get the taper attachment . But that's why mine was only 700 bucks, and the guy I got it from obtained a brand new lathe for free and wanted the old south bend gone.

I did get the taper attachment . But that's why mine was only 700 bucks, and the guy I got it from obtained a brand new lathe for free and wanted the old south bend gone.