Sachmanram

Stainless

- Joined

- Jan 17, 2011

- Location

- New Brunswick, Canada

I am not certain if this belongs in this forum or the antique forum, or perhaps, none at all.

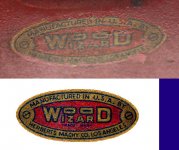

When I first saw this lathe on Kijiji with one bad picture, I thought that it may have been an early South Bend 9, although the headstock looked rather odd. It turns out to be a Canadian made Moody lathe manufactured in Terribone Quebec by the Matthew Moody and Sons co.

It is an awful dirty mess right now, but there is little rust and lots of grease, so I believe that it will clean up just fine.

Here's a few pics....

The former owner and his son in the background and my brother with his head clipped off...

It didn't come with much, but the original drive is present and was removed for the journey. It also came with the change gears, a 4-jaw chuck and a steady rest.

I have already begun dismantling the lathe and have removed the apron, compound rest, cross-slide and saddle. After cleaning the ways with some varsol on a rag, I was pleasantly suprised to see flaking visible everywhere with very little wear near the headstock.

I am having difficulty in removing the compound rest spindle from the slide. I can remove the nut and ball crank as well as the micrometer dial, but that's as far as I can get. Is the "pointer" or zeroing collar behind the micrometer dial integral to the rest or is that pressed in or threaded in ? I realize that this isn't a South Bend, but believe that it may be constructed very similarly. Any of you with a South Bend 9 have any help, it would be appreciated.

Here's a pic of the assembly...

I will post pics of the tear down and clean up as I go along.

Cheers....

Brian

When I first saw this lathe on Kijiji with one bad picture, I thought that it may have been an early South Bend 9, although the headstock looked rather odd. It turns out to be a Canadian made Moody lathe manufactured in Terribone Quebec by the Matthew Moody and Sons co.

It is an awful dirty mess right now, but there is little rust and lots of grease, so I believe that it will clean up just fine.

Here's a few pics....

The former owner and his son in the background and my brother with his head clipped off...

It didn't come with much, but the original drive is present and was removed for the journey. It also came with the change gears, a 4-jaw chuck and a steady rest.

I have already begun dismantling the lathe and have removed the apron, compound rest, cross-slide and saddle. After cleaning the ways with some varsol on a rag, I was pleasantly suprised to see flaking visible everywhere with very little wear near the headstock.

I am having difficulty in removing the compound rest spindle from the slide. I can remove the nut and ball crank as well as the micrometer dial, but that's as far as I can get. Is the "pointer" or zeroing collar behind the micrometer dial integral to the rest or is that pressed in or threaded in ? I realize that this isn't a South Bend, but believe that it may be constructed very similarly. Any of you with a South Bend 9 have any help, it would be appreciated.

Here's a pic of the assembly...

I will post pics of the tear down and clean up as I go along.

Cheers....

Brian