bradjacob

Titanium

- Joined

- Nov 18, 2008

- Location

- Easton, PA

If you saw my previous post on being scammed from some wishy-washy, shady jackass, this will be poetic justice!

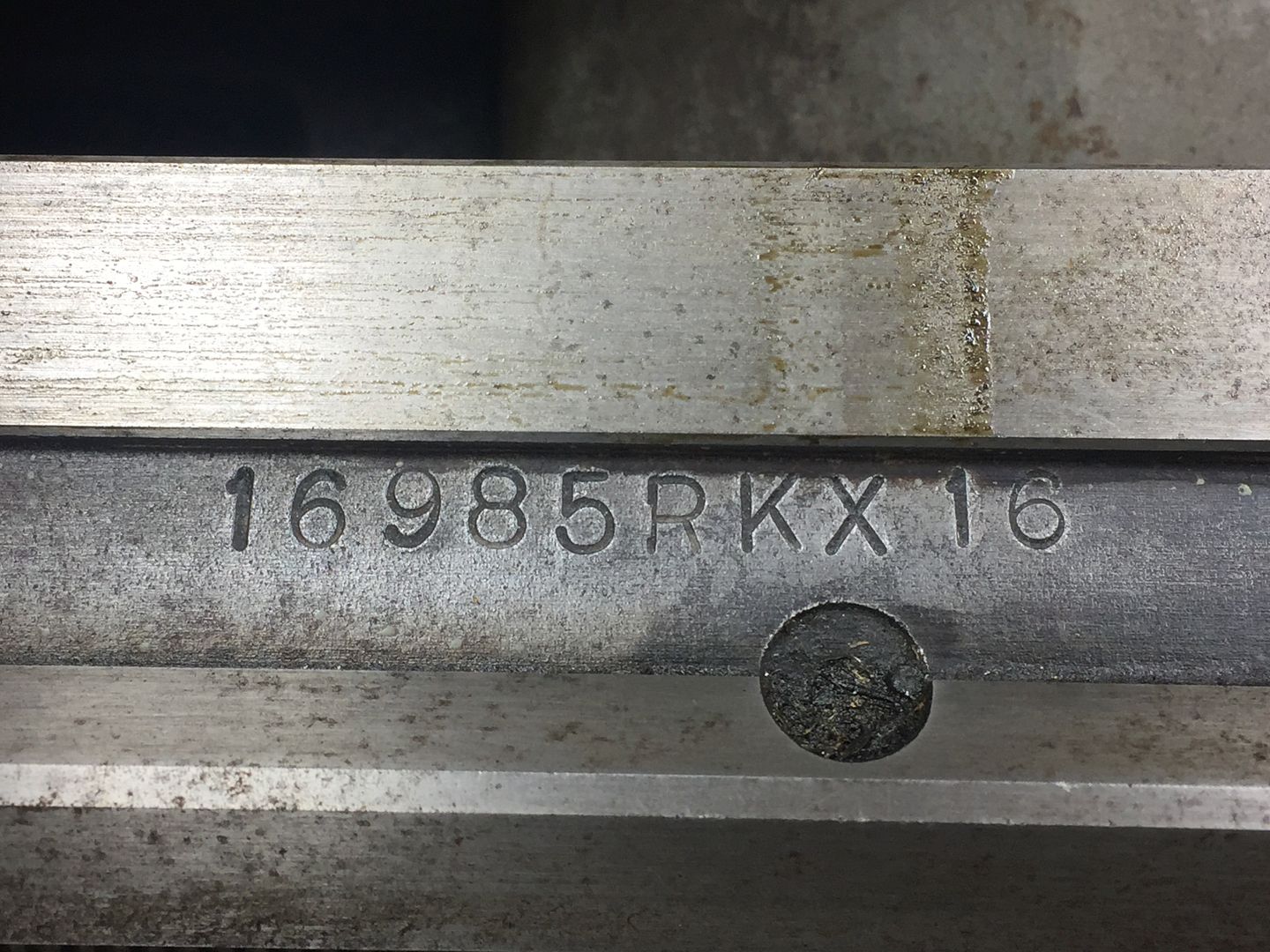

After my upset, I was scanning every possible avenue to find another Heavy 10. I found one on eBay and called the seller directly at his company. *(he used the same name for his eBay handle).

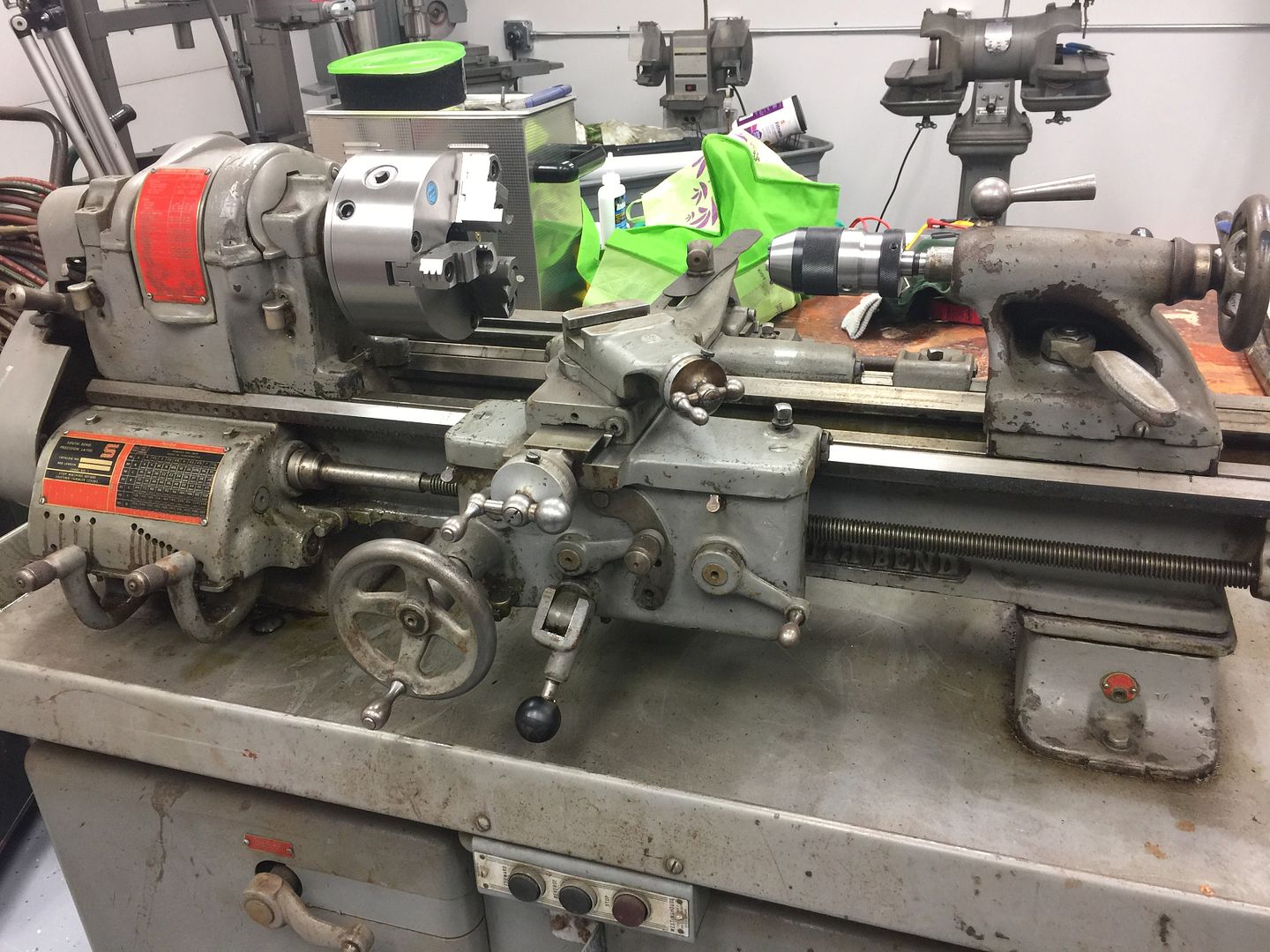

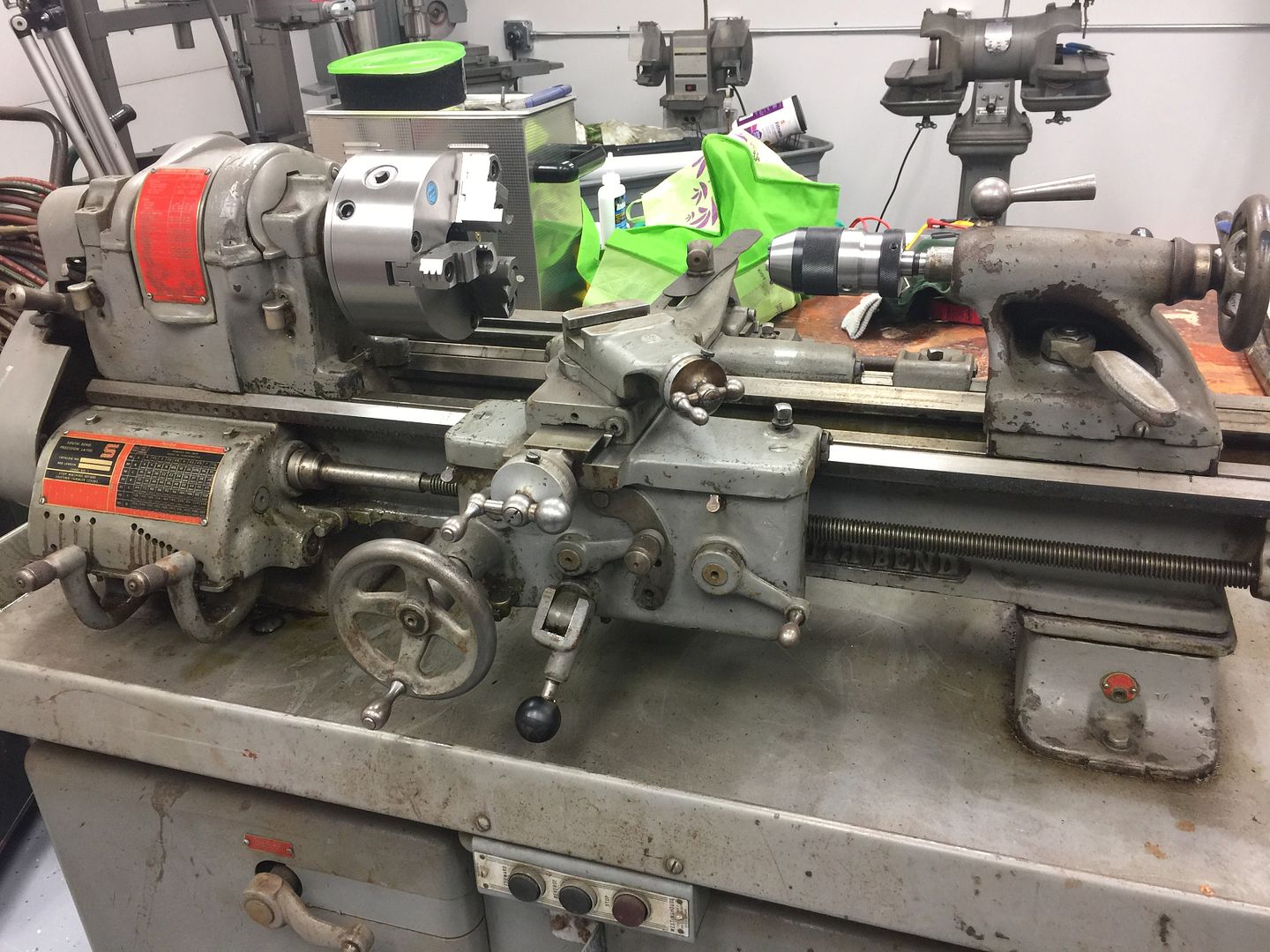

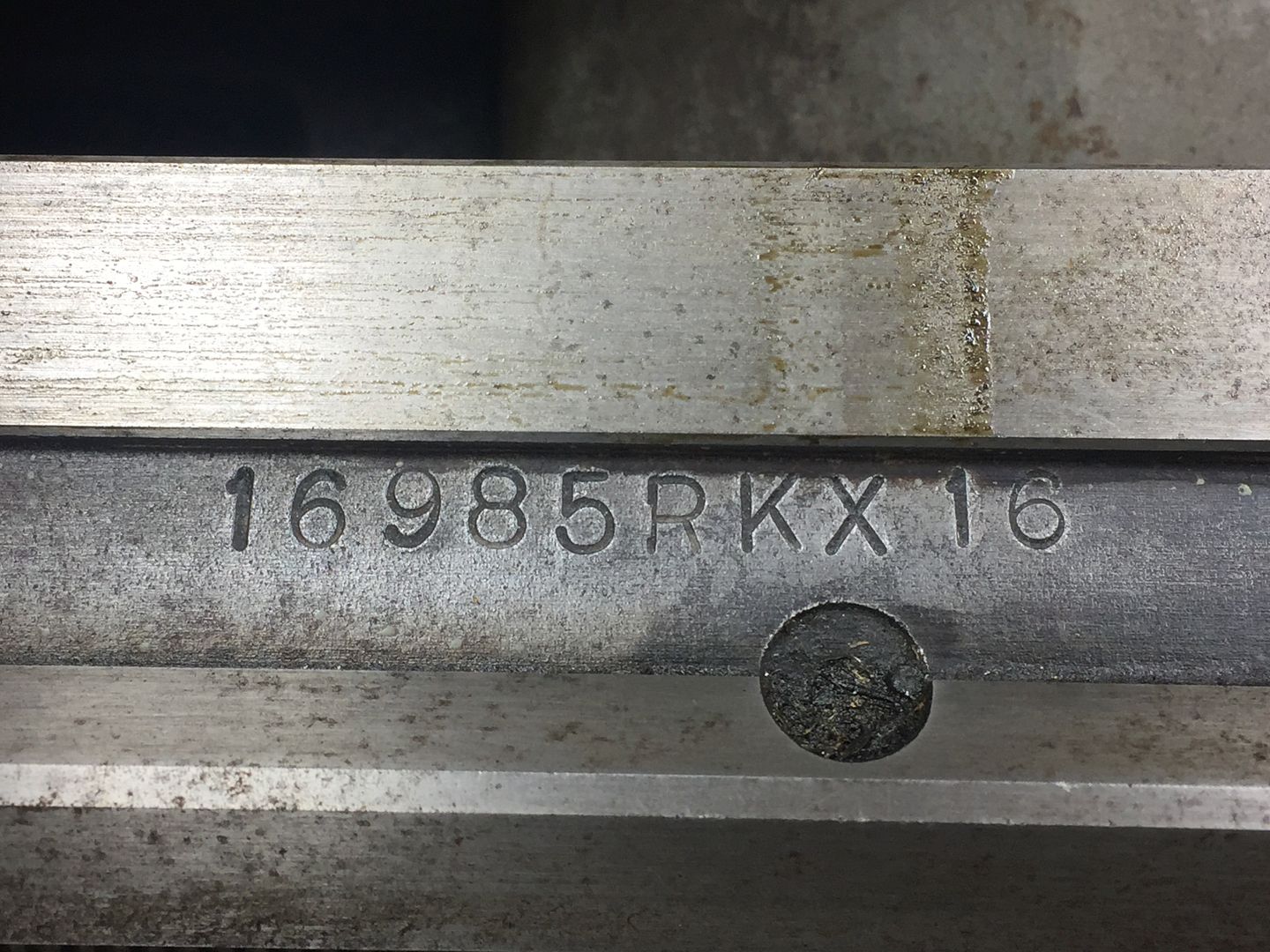

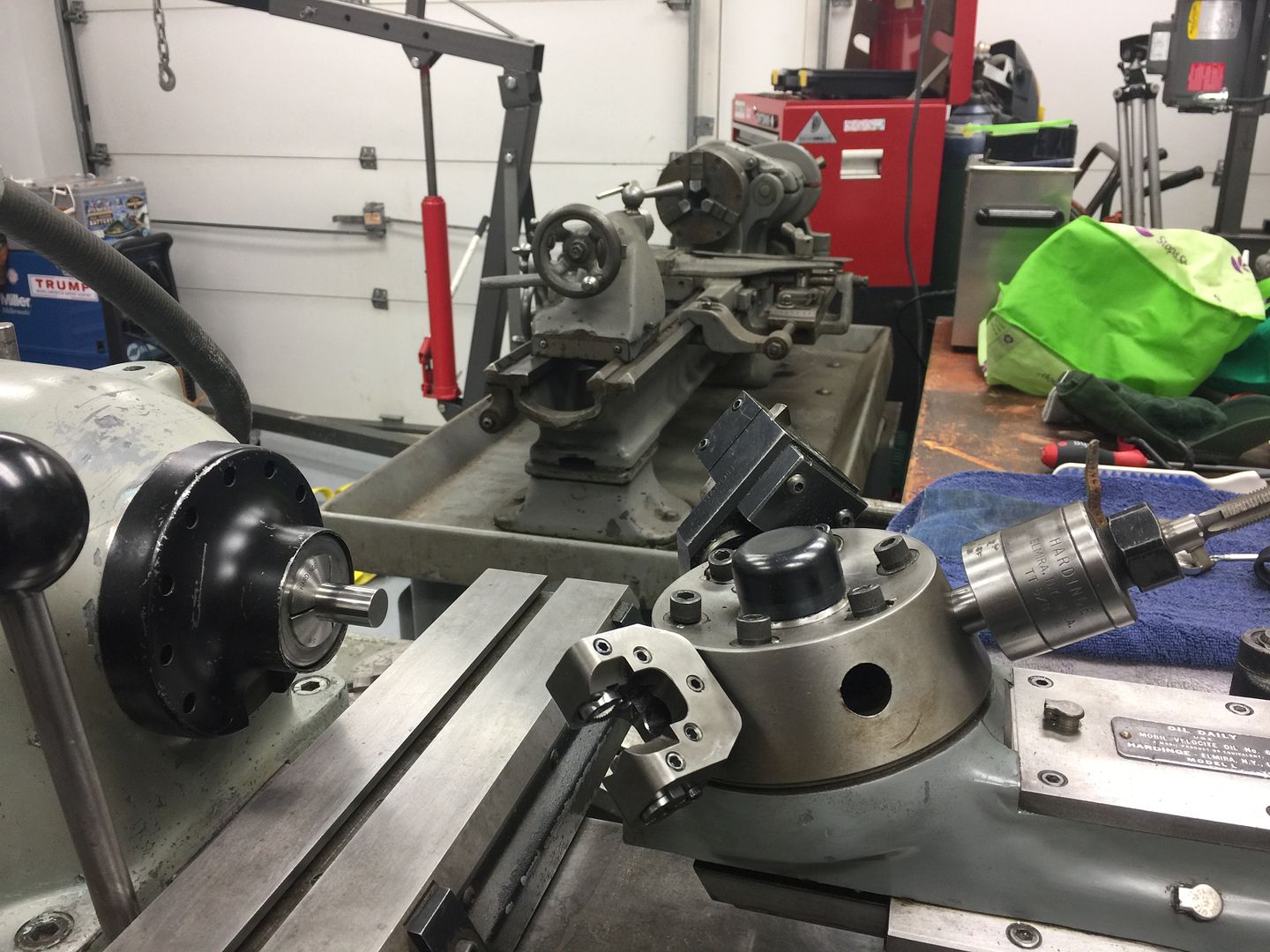

Heavy 10, 4 foot (hard) bed, great amount of tooling, etc, etc... for $1,800. DIRTY - but I know the machine will be a great one! Dirt and grime are only temp obstacles.

All of a sudden, the SAME model (as the jerk scammer) comes up on Craigslist. It "looked" nice, so I called.

Guy reassured me that it was in fantastic condition mechanically, but simply dirty from being in a sheet metal factory for years.

Little to no use, bla bla bla...

Ok, I'm excited now. I asked for some detailed pics. Got them. Looks promising.

I rent the trailer, jump through some hoops, do the dance - and schedule some time to see it. THAT NIGHT! No way, would I loose out again.

When my eyes finally met the machine, I just KNEW!

ALL the following checked out amazing:

1. No bed wear, whatsoever

2. No slop in the carriage wheel

3. Oil in the spindle cups

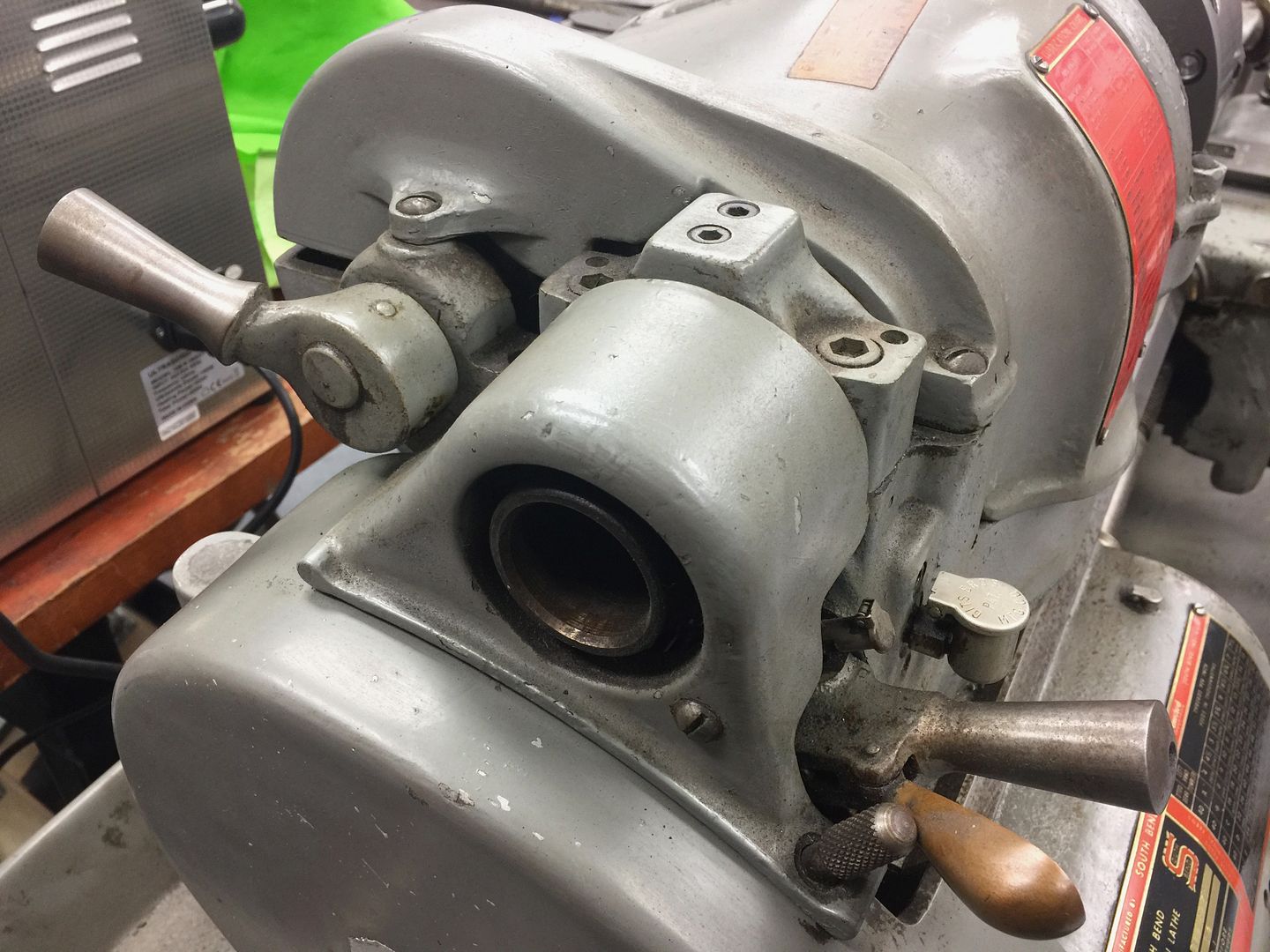

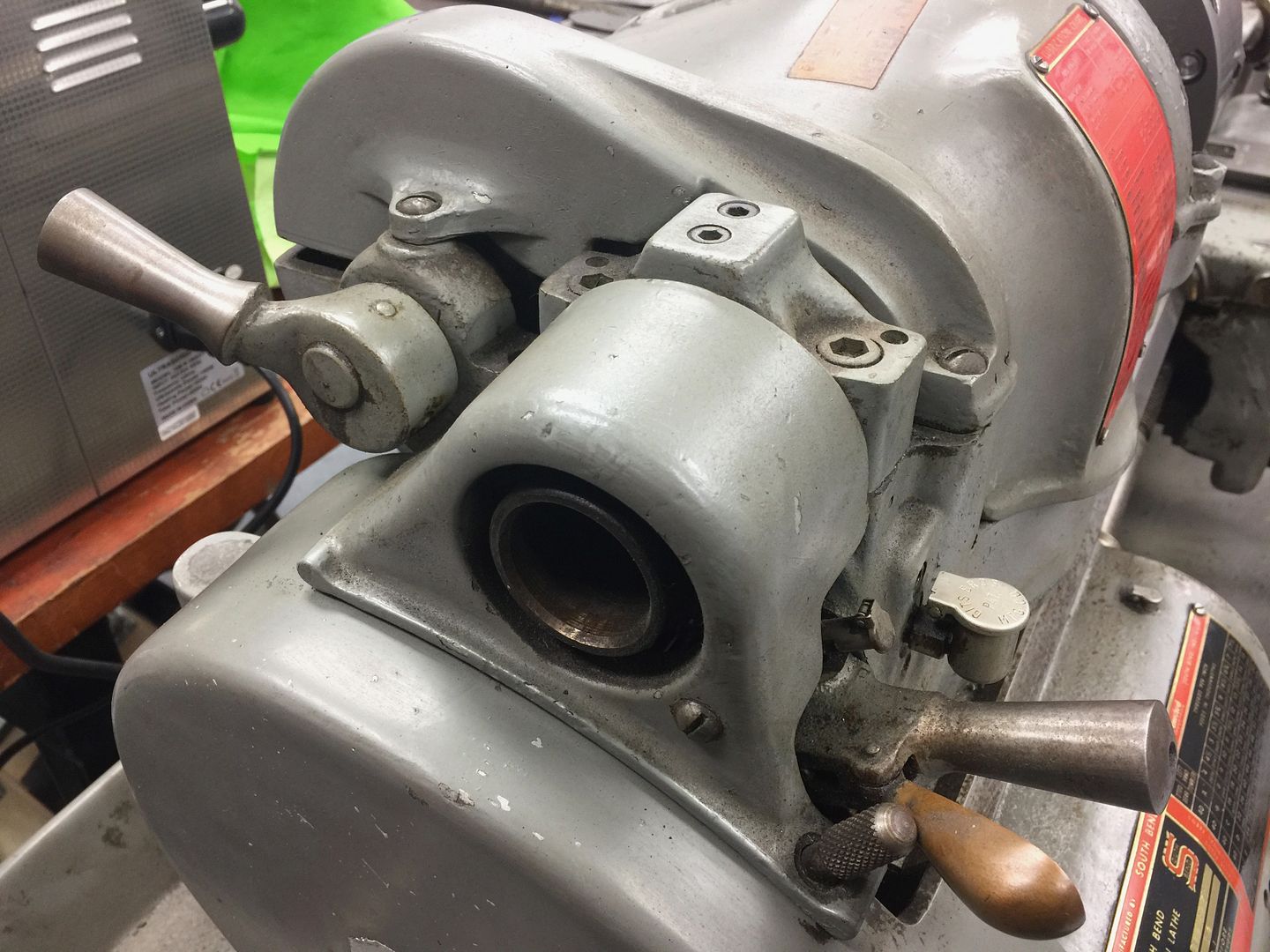

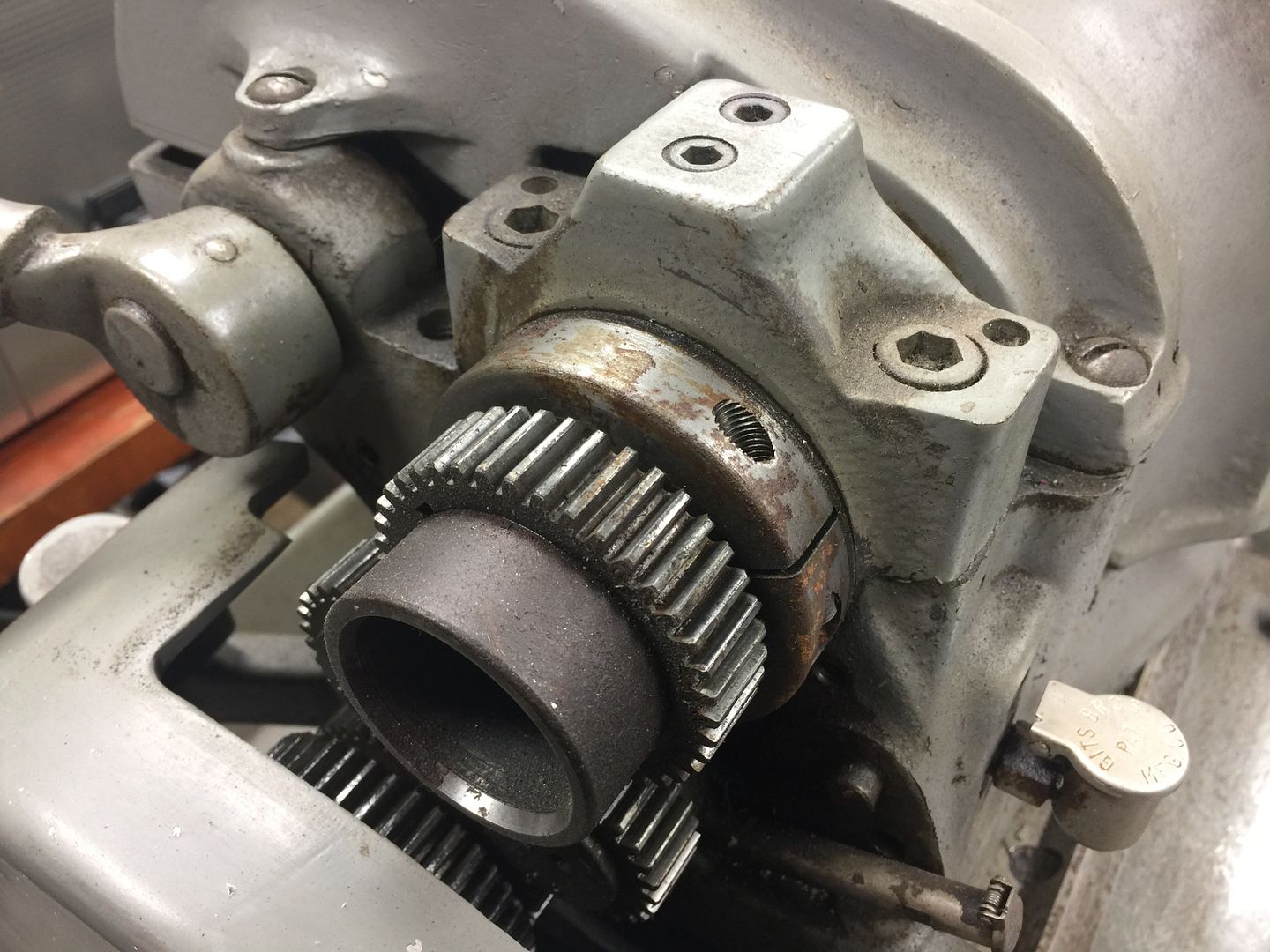

4. Oil in the apron

5. Oil cup lids all snapped back nicely.

6. Knurling on side-gear cover, was prickly

7. Knurling on tailstock nut, was prickly

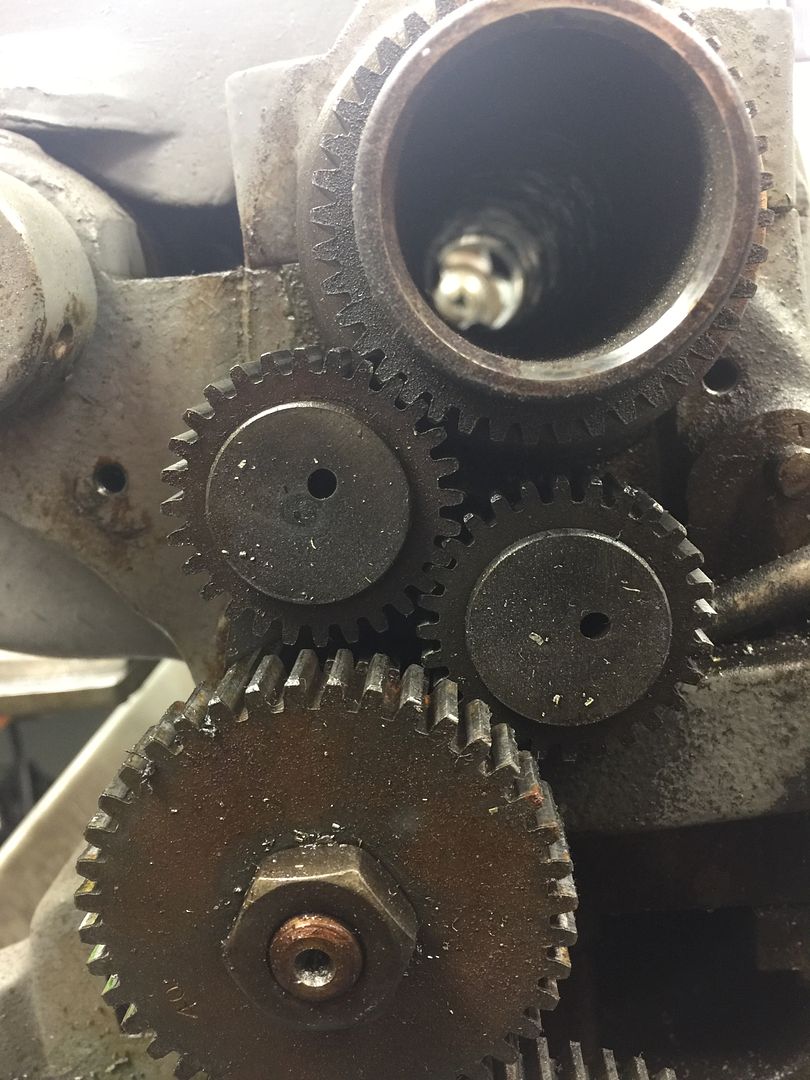

8. Twin-gears, spindle gear and idlers had visibly, NO wear. They looked as if they were NOS

9. FULL travel of (both) the compound and cross-feed with ZERO binding

10. scraping visible on both the compound and cross-feed ways

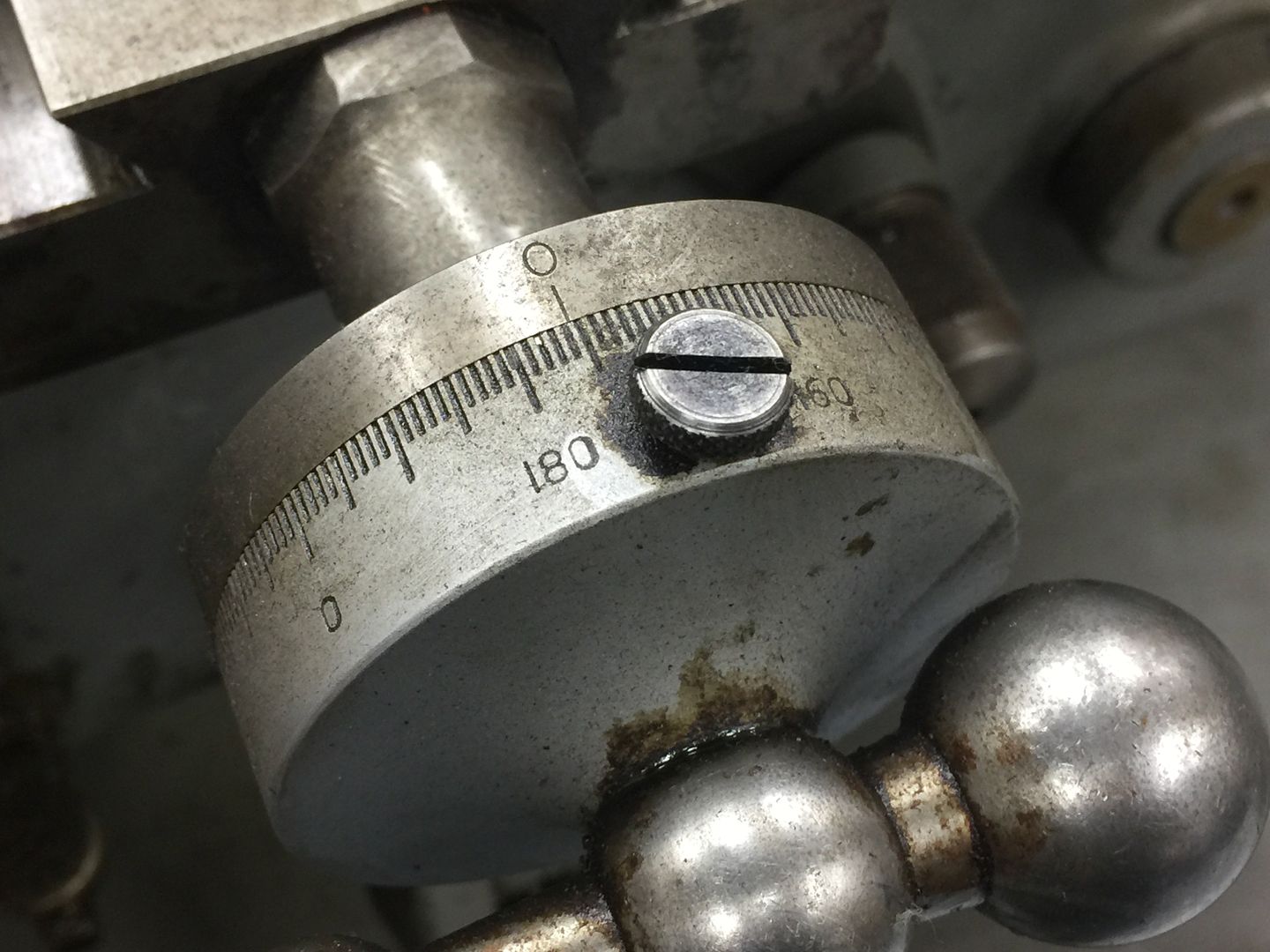

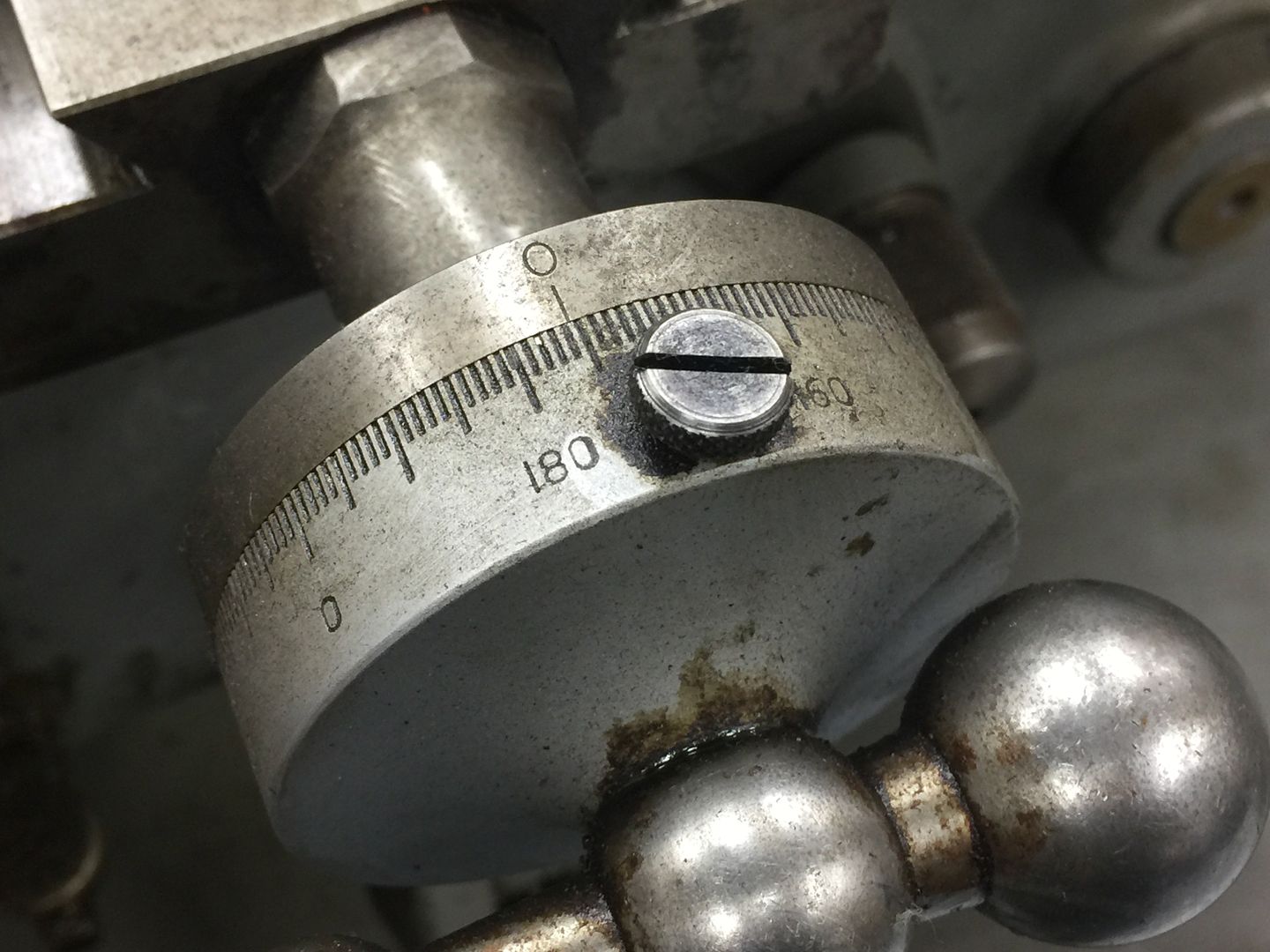

11. Cross feed and compound dials showed ZERO boogering, scratches, nicks or dings.

12. Compound casting has no crash marks

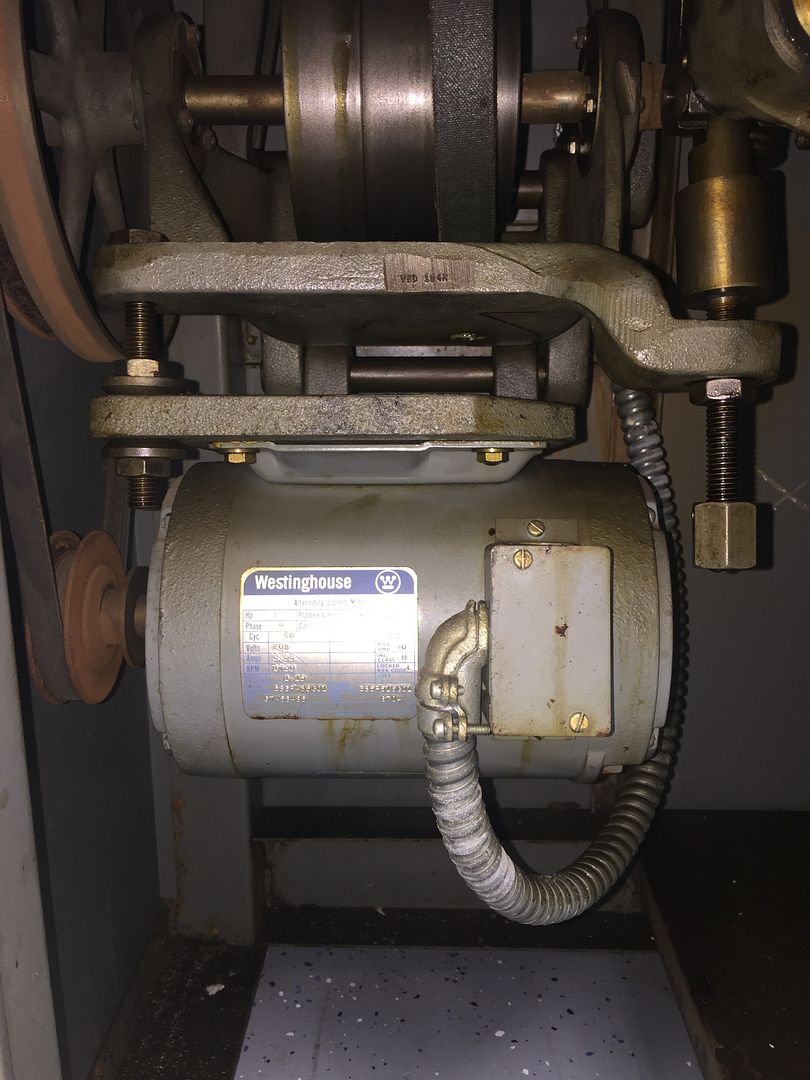

13. Under-drive was free of oil & swarf

14. Under-drive showed small amounts of light surface rust - as if it was from humidity.

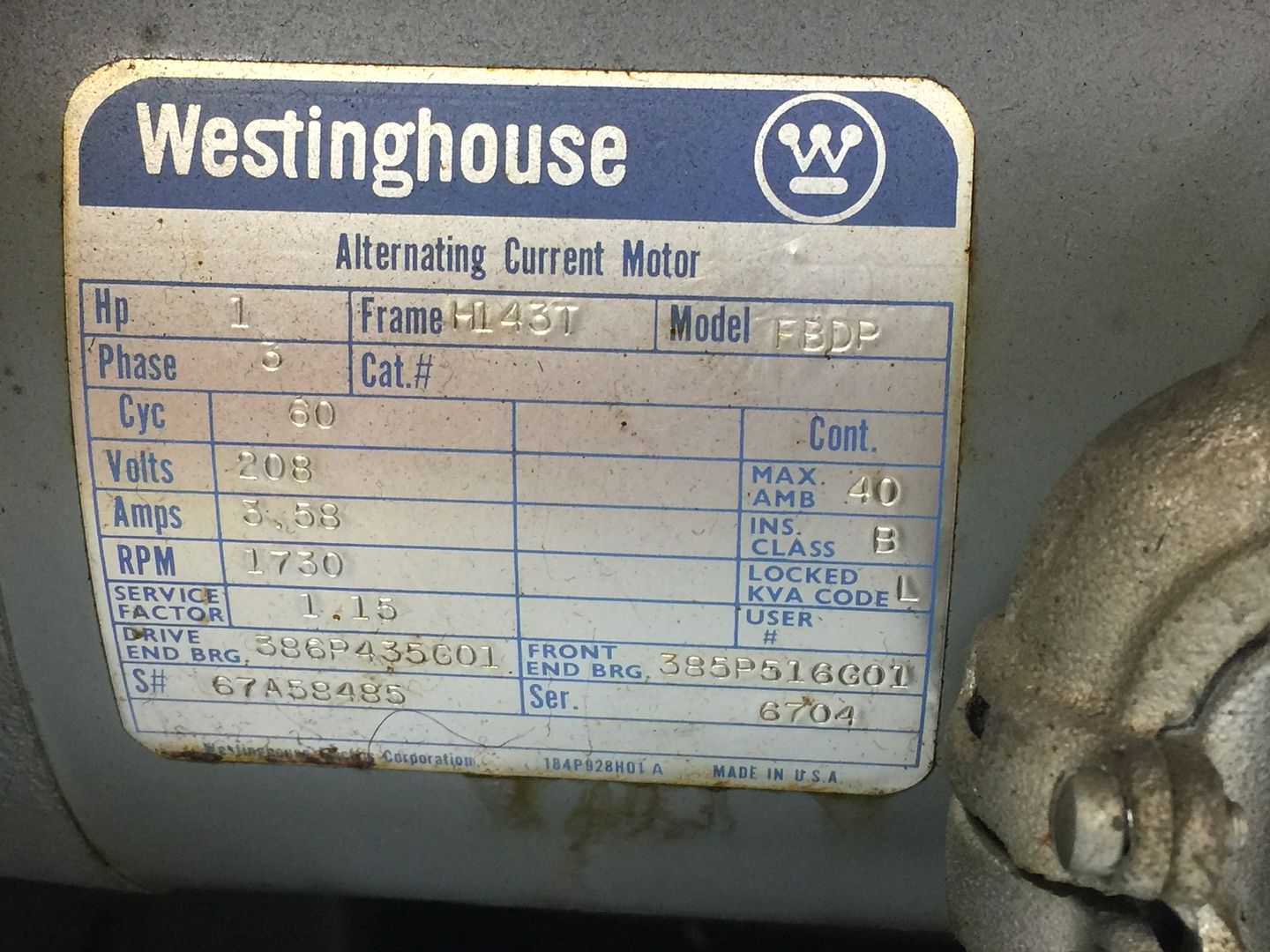

15. Motor was clean free of oil/dust

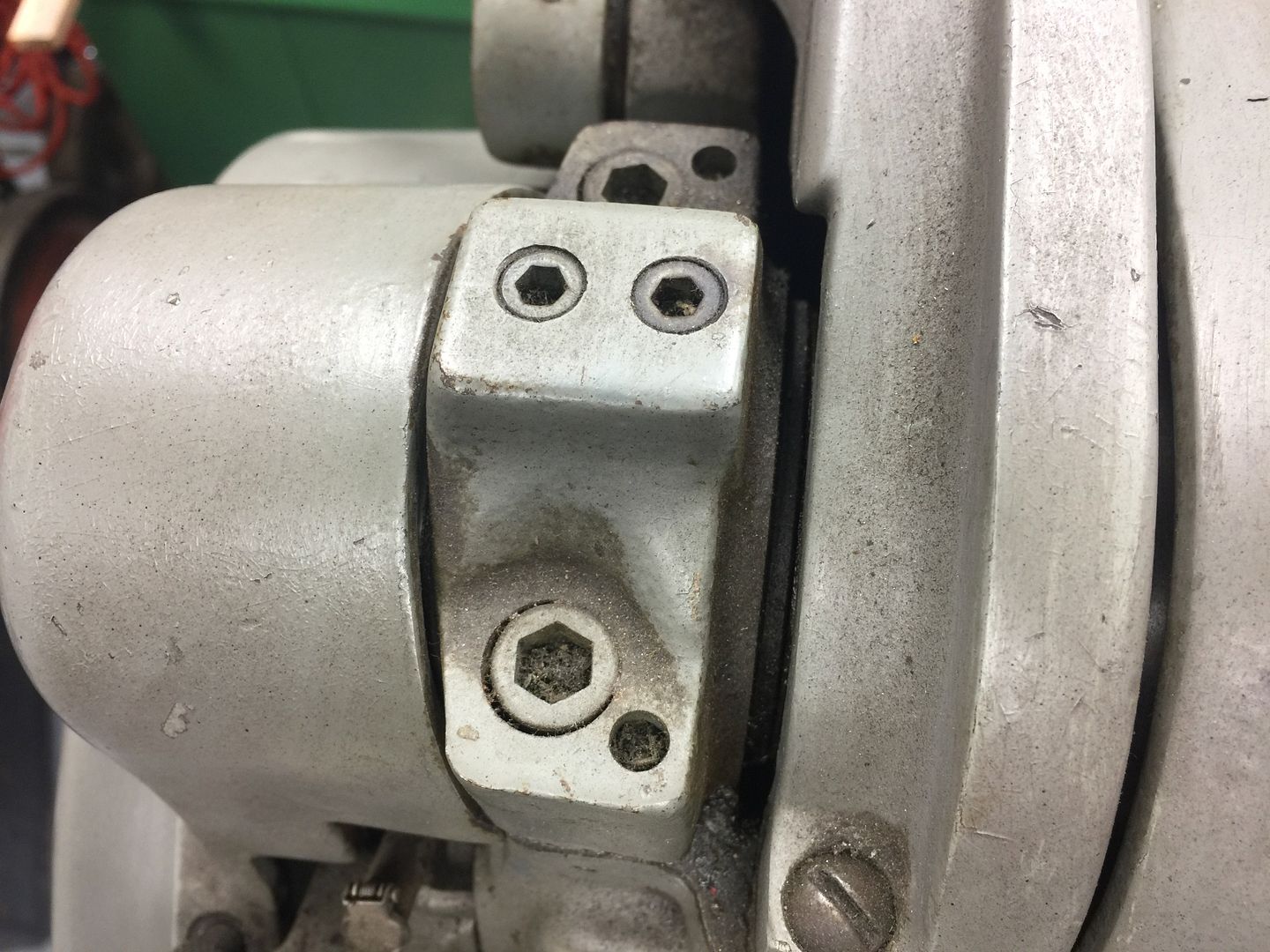

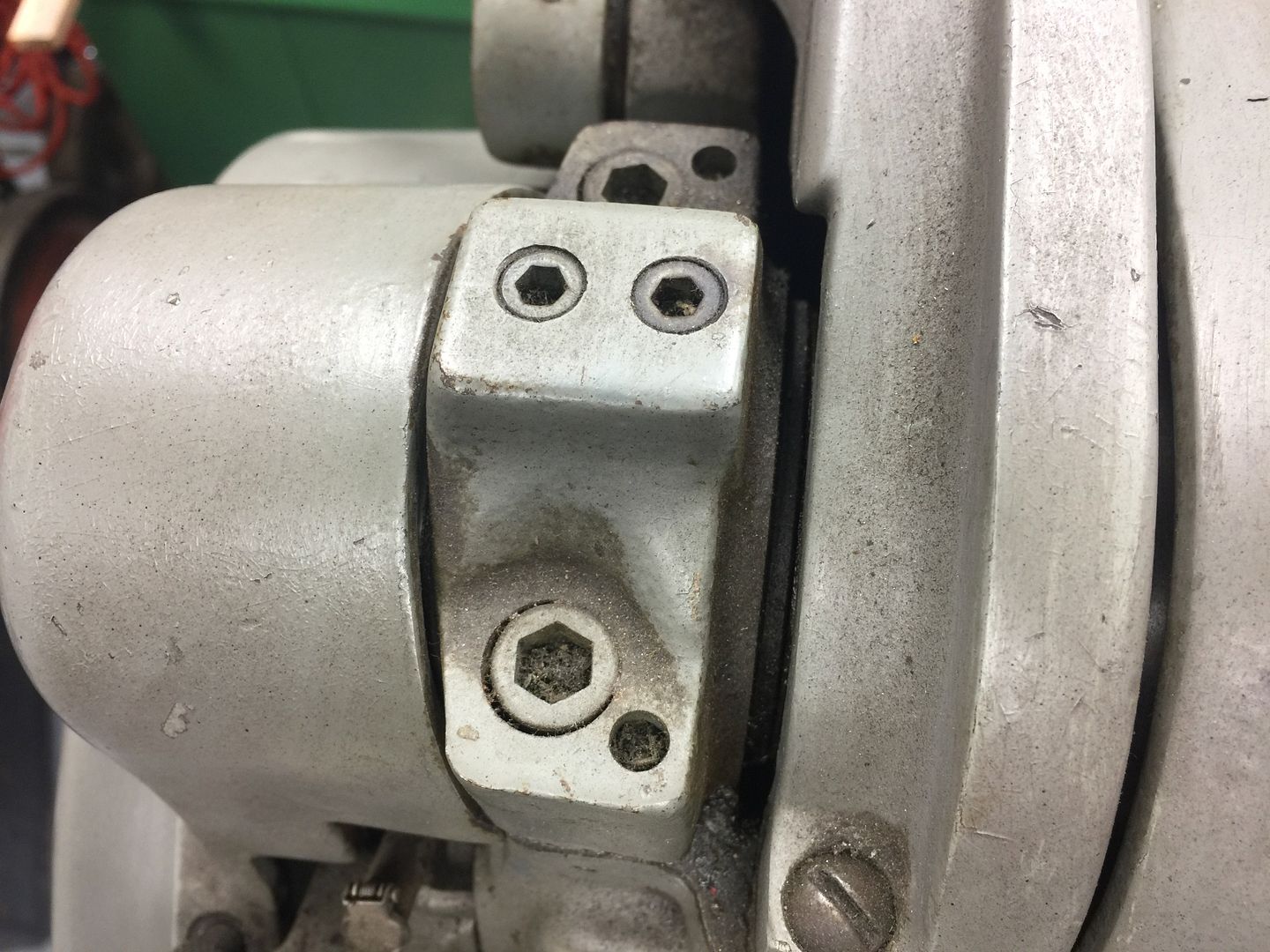

16. Headstock bearing caps screws appear to have never been unscrewed.

17. Gearbox plate is free of dents, dings or scratches

18. All gibs are sticking out far, which means they haven'y been cranked inward to compensate for wear

19. Spindle spins silky smooth as does the back gears, cone-pulley and back-gear-lever

20. Overall, the machine looks and FEELS very solid, smooth and tight. Just like the seller said - very little use.

I'm about to embark on a full disassembly in order to clean, degrease, re-wick and reassembly. I'm not bothering to paint it, because I need to being using it, as soon as possible.

For $1,900, the machine came with a LANTERN post, set of Armstrong Tool holders, Jacobs drill-chuck and a 3-jaw Buck, Adjust-Tru chuck.

Not too shabby!

I'll let the pics speak for themselves. And I'll post "after" pics once the cleanup is complete.

After my upset, I was scanning every possible avenue to find another Heavy 10. I found one on eBay and called the seller directly at his company. *(he used the same name for his eBay handle).

Heavy 10, 4 foot (hard) bed, great amount of tooling, etc, etc... for $1,800. DIRTY - but I know the machine will be a great one! Dirt and grime are only temp obstacles.

All of a sudden, the SAME model (as the jerk scammer) comes up on Craigslist. It "looked" nice, so I called.

Guy reassured me that it was in fantastic condition mechanically, but simply dirty from being in a sheet metal factory for years.

Little to no use, bla bla bla...

Ok, I'm excited now. I asked for some detailed pics. Got them. Looks promising.

I rent the trailer, jump through some hoops, do the dance - and schedule some time to see it. THAT NIGHT! No way, would I loose out again.

When my eyes finally met the machine, I just KNEW!

ALL the following checked out amazing:

1. No bed wear, whatsoever

2. No slop in the carriage wheel

3. Oil in the spindle cups

4. Oil in the apron

5. Oil cup lids all snapped back nicely.

6. Knurling on side-gear cover, was prickly

7. Knurling on tailstock nut, was prickly

8. Twin-gears, spindle gear and idlers had visibly, NO wear. They looked as if they were NOS

9. FULL travel of (both) the compound and cross-feed with ZERO binding

10. scraping visible on both the compound and cross-feed ways

11. Cross feed and compound dials showed ZERO boogering, scratches, nicks or dings.

12. Compound casting has no crash marks

13. Under-drive was free of oil & swarf

14. Under-drive showed small amounts of light surface rust - as if it was from humidity.

15. Motor was clean free of oil/dust

16. Headstock bearing caps screws appear to have never been unscrewed.

17. Gearbox plate is free of dents, dings or scratches

18. All gibs are sticking out far, which means they haven'y been cranked inward to compensate for wear

19. Spindle spins silky smooth as does the back gears, cone-pulley and back-gear-lever

20. Overall, the machine looks and FEELS very solid, smooth and tight. Just like the seller said - very little use.

I'm about to embark on a full disassembly in order to clean, degrease, re-wick and reassembly. I'm not bothering to paint it, because I need to being using it, as soon as possible.

For $1,900, the machine came with a LANTERN post, set of Armstrong Tool holders, Jacobs drill-chuck and a 3-jaw Buck, Adjust-Tru chuck.

Not too shabby!

I'll let the pics speak for themselves. And I'll post "after" pics once the cleanup is complete.

You must be doubly stoked about finding that lathe, after the frustrating experience with the first seller. I wish that there were buys like that around here. We have to be content to fix up old clapped out machines.

You must be doubly stoked about finding that lathe, after the frustrating experience with the first seller. I wish that there were buys like that around here. We have to be content to fix up old clapped out machines.