ng19delta

Aluminum

- Joined

- Jun 24, 2014

- Location

- Merchantville, NJ

I have a simple question regarding the threading dial on my South Bend 9A... I understand how to use it, but this is about how it operates... I have tried experimentally cutting threads so far, but am still in the learning/practice phase.

What I have noticed is that when I set the thread gauge, it engages the screw drive thread and starts turning- This is normal... Then, when I engage the half-nuts (when it reaches the prescribed index)it kicks back out of the threads, and while the cut takes place it is disengaged, and I have to re-engage it when I go for my next pass. Is this normal?

I haven't found reference to this particular question in HTRAL, so I figured I'd better ask here, as I am trying to learn how my lathe operates and how to use it well...

Thanks!

Scott

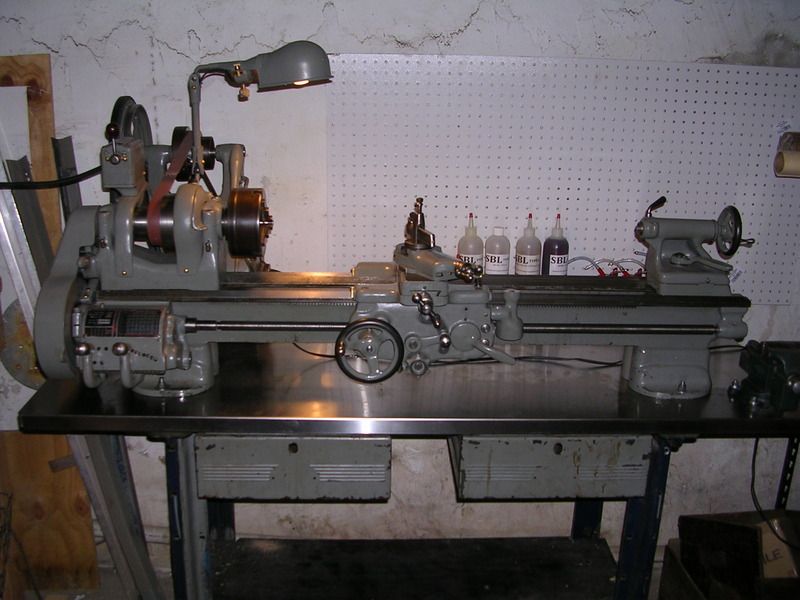

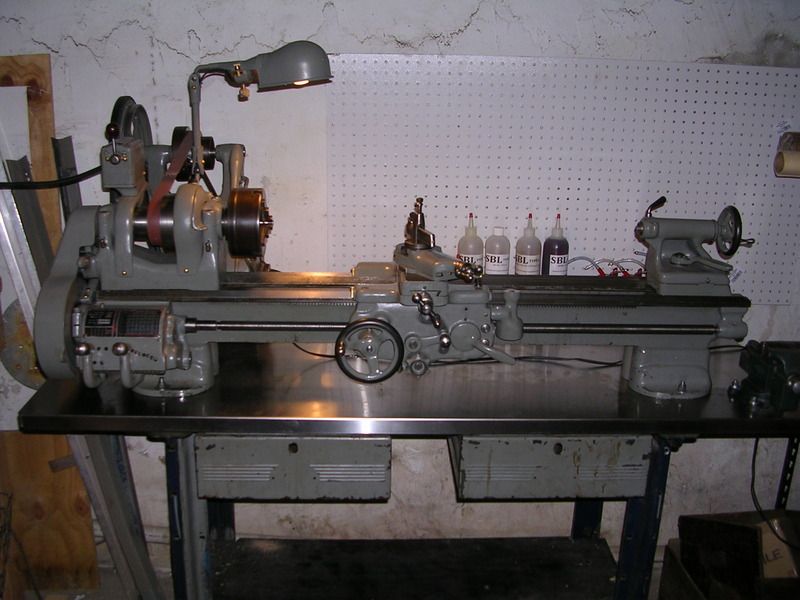

(Here's a pic- I restored her a year or two ago... I'm waiting for the plate to do the reverse lever quick-change conversion- should be here tomorrow!)

What I have noticed is that when I set the thread gauge, it engages the screw drive thread and starts turning- This is normal... Then, when I engage the half-nuts (when it reaches the prescribed index)it kicks back out of the threads, and while the cut takes place it is disengaged, and I have to re-engage it when I go for my next pass. Is this normal?

I haven't found reference to this particular question in HTRAL, so I figured I'd better ask here, as I am trying to learn how my lathe operates and how to use it well...

Thanks!

Scott

(Here's a pic- I restored her a year or two ago... I'm waiting for the plate to do the reverse lever quick-change conversion- should be here tomorrow!)