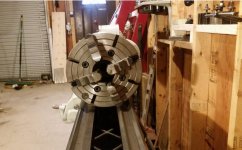

This 4-jaw chuck which came with my recently purchased South Bend 13 has me puzzled.

It is 12 1/2" in diameter, which is too large to be of any practical use that I can see, which might explain why it looks like it's never been used. Am I just being dense, is there's some use for this thing I'm not aware of? You can only clamp a four inch piece in it before the jaws hit the ways, while you can clamp an eight inch piece in the 10 inch chuck.

I would like to sell it and put the money back in my lathe, but I need to figure out just what I've got and who's going to be able to use it. I can find no markings on it whatsoever but the paint exactly matches the original SB paint, not that that means anything, and the back plate appears to me to be original.

Thing is, if this is too big to use on a 13, and (as far as I can tell) all of the larger lathes have larger spindles, then why would they sell a chuck with a 2 1/4-8 back plate when the damn thing is too big for any of the lathes that take that size spindle? Are there larger lathes that have this size spindle that I'm not aware of?

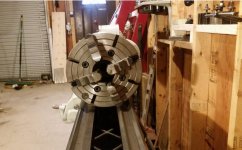

It is 12 1/2" in diameter, which is too large to be of any practical use that I can see, which might explain why it looks like it's never been used. Am I just being dense, is there's some use for this thing I'm not aware of? You can only clamp a four inch piece in it before the jaws hit the ways, while you can clamp an eight inch piece in the 10 inch chuck.

I would like to sell it and put the money back in my lathe, but I need to figure out just what I've got and who's going to be able to use it. I can find no markings on it whatsoever but the paint exactly matches the original SB paint, not that that means anything, and the back plate appears to me to be original.

Thing is, if this is too big to use on a 13, and (as far as I can tell) all of the larger lathes have larger spindles, then why would they sell a chuck with a 2 1/4-8 back plate when the damn thing is too big for any of the lathes that take that size spindle? Are there larger lathes that have this size spindle that I'm not aware of?