WILLEO6709

Diamond

- Joined

- Nov 6, 2001

- Location

- WAPELLO, IA USA

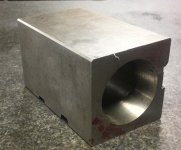

I got tired of all the ER collet blocks out there being cheap junk from some country I never heard of and without a back stop. I mean who wants an ER top loading collet block without a way to backstop it......if you are doing more that one part its so much faster.

These are all 2 inch square and 2 inch hex. The ER32's have about a .938 through hole, the er40's have a 1.220 through hole. The ER32's use a round stop disc, the ER40's use a rectangular stop plate due to the larger bore. Right not the stop screw is tapped 1/2-13. These are made of P-20 prehard, Rc 28-32. These were turned and rough milled on an Okuma LB3000EXII-MYW Turning center, then ground to size.

Pricing depends on if you want the nut. Hex and square same price.

ER 32 hex or square $ 175.00 ground with the nut

$ $140.00 ground without the nut

$100.00 each " you grind"

ER 40 hex or square $ 200.00 ground with the nut

$ $165.00 ground without the nut

$120.00 each " you grind"

Buy a pair and save $20.00 on the total.

ships from Wapello, IA 52653 flat rate $12.50 per order.

Other sizes may be available in the future depending on requests.

These are all 2 inch square and 2 inch hex. The ER32's have about a .938 through hole, the er40's have a 1.220 through hole. The ER32's use a round stop disc, the ER40's use a rectangular stop plate due to the larger bore. Right not the stop screw is tapped 1/2-13. These are made of P-20 prehard, Rc 28-32. These were turned and rough milled on an Okuma LB3000EXII-MYW Turning center, then ground to size.

Pricing depends on if you want the nut. Hex and square same price.

ER 32 hex or square $ 175.00 ground with the nut

$ $140.00 ground without the nut

$100.00 each " you grind"

ER 40 hex or square $ 200.00 ground with the nut

$ $165.00 ground without the nut

$120.00 each " you grind"

Buy a pair and save $20.00 on the total.

ships from Wapello, IA 52653 flat rate $12.50 per order.

Other sizes may be available in the future depending on requests.