ncologerojr

Plastic

- Joined

- Oct 25, 2014

- Location

- Upstate, NY

I recently purchased a Bridgeport M-Head with a 1/2hp 220v 3-phase motor.

I ordered a Teco-Westinghouse L510 VFD which is rated for up to 1hp motor wired with 110v single phase in, 3-phase out.

https://www.tecowestinghouse.com/Manuals/L510_instruction_manual.pdf

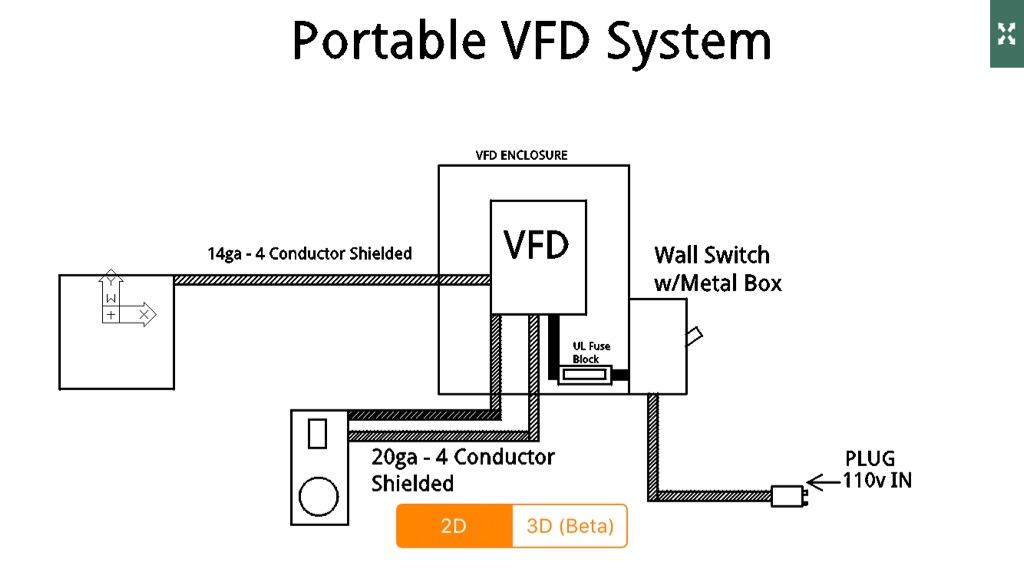

I am gathering supplies and materials to wire everything up. I plan to mount the electrical components on a board which can be plugged into a 15amp receptacle, as I may choose to re-locate the mill as I put it to use. I would like to use the stock Bridgeport FWD/REV switch and a remote potentiometer for speed control. I've read that you should have a fuse and shut-off between the workshop panel box and the VFD, so I am planning to use a fusible disconnect switch.

I drew up the simple wiring diagram to get started with the basic layout. Can anyone weigh in on this? Am I headed in the right direction?

I ordered a Teco-Westinghouse L510 VFD which is rated for up to 1hp motor wired with 110v single phase in, 3-phase out.

https://www.tecowestinghouse.com/Manuals/L510_instruction_manual.pdf

I am gathering supplies and materials to wire everything up. I plan to mount the electrical components on a board which can be plugged into a 15amp receptacle, as I may choose to re-locate the mill as I put it to use. I would like to use the stock Bridgeport FWD/REV switch and a remote potentiometer for speed control. I've read that you should have a fuse and shut-off between the workshop panel box and the VFD, so I am planning to use a fusible disconnect switch.

I drew up the simple wiring diagram to get started with the basic layout. Can anyone weigh in on this? Am I headed in the right direction?