Space_Cadet

Plastic

- Joined

- Aug 12, 2016

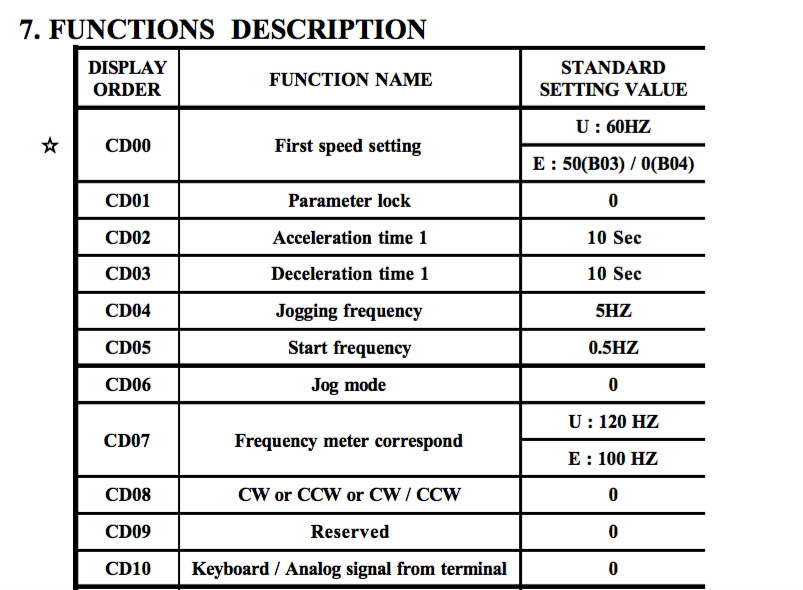

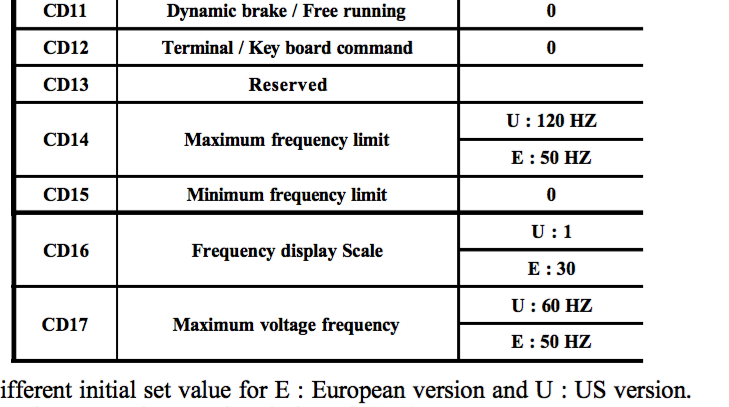

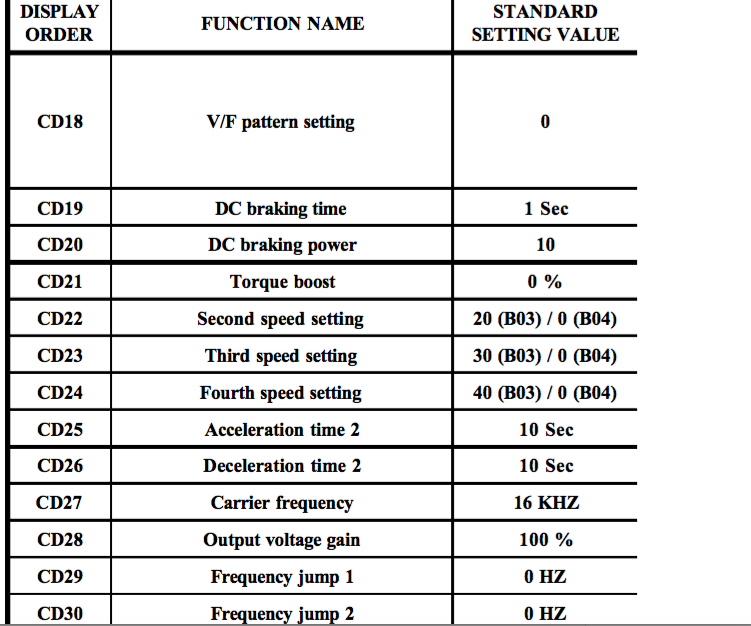

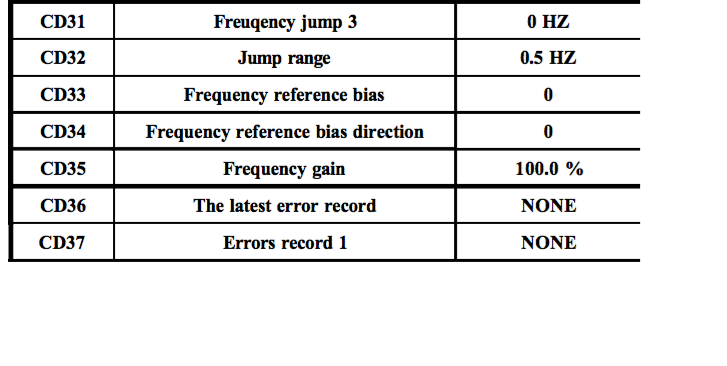

I bought this motor recently for my Schaublin lathe, is 0.75kw, 1hp motor, wired to a VFD and can't figure our what can it be, it is wired in delta.

BE CAREFUL HEADPHONE USERS AT 0:35 SOUND GOES UP

BE CAREFUL HEADPHONE USERS AT 0:35 SOUND GOES UP