mwr

Aluminum

- Joined

- Apr 1, 2009

- Location

- Southern California

Sorry if this isn't the ideal forum for this, I couldn't think of a better one.

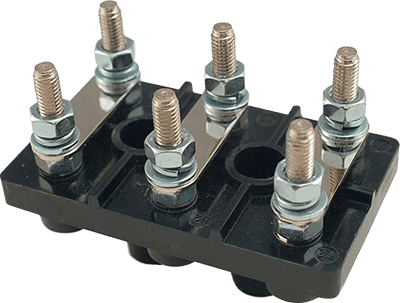

I need a few of these connectors which I don't even know a name for. It is a threaded cylindrical screw terminal about 10mm dia and 15mm long, with a post down the middle to squish a wire at the bottom of a slotted, threaded post. Hopefully the pics will explain it all. I could make them but if they're something common then I'd rather spend my time doing something else.. Thank you

I need a few of these connectors which I don't even know a name for. It is a threaded cylindrical screw terminal about 10mm dia and 15mm long, with a post down the middle to squish a wire at the bottom of a slotted, threaded post. Hopefully the pics will explain it all. I could make them but if they're something common then I'd rather spend my time doing something else.. Thank you