NormanW

Plastic

- Joined

- Sep 19, 2014

- Location

- Split-Dalmatia

Motor wiring conundrum

Wiring on a Chinese motor

I purchased a new woodworking machine for making mortice and tennon joints and planing timber. The machine was made in China and came from India. I can't get help from the vendor, so am working through this myself. There is no manual although with the exception of the wiring, it is extremely robust and appears well made. Built by blacksmiths comes to mind.

When it arrived I checked it over and found that there was just a two pin plug, no earth, with 1.5mm copper cable in a blue and a brown sheath. This looked like lighting cable and for a 2HP motor seemed inadequate.

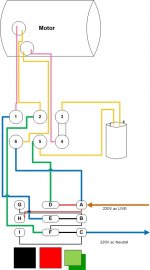

When I looked inside the plastic peckerhead cover on the motor, there are two red leads and four yellow leads that go to the motor. Connecting the switch to the motor were four leads, two blue and two green and yellow (earth cable), and a green and yellow earth lead that is not connected to anything. There is no wiring diagram. The wiring was not well done with stray copper wire ends coming from connectors.

I didn't try the motor in this configuration. Rather, with a circuit tester I traced which wire went where, then put in a new 5 core cable, brown, blue, black, grey and earth from this block to the switch (and a 3 core power lead). Brown is live (one of the blue wires), blue is return and the grey and black replace the two green/yellow leads that were present.

When I turn the switch on, I get loud buzzing from the motor, but no movement. I only try it for a second or two and it doesn't trip the RCD. The motor turns freely by hand. The switch has three buttons, green, black and red. Red is obvious, but I suspect the green and black buttons are about motor speed. Again, no instructions but with the circuit tester the voltage is directed in different pathways according to which button is pressed.

I have replicated exactly the wiring I found, only with an earth, and normal coloured cables, but clearly something is wrong.

I have tried to locate a company website but failed and although I have the machine name and number, there is nothing on the internet for it. I suspect it was manufactured some time ago, although everything was wrapped in brown wax paper, protected and greased, it just looks so 1960's.

Thanks for reading, any help would be appreciated.

NW

Wiring on a Chinese motor

I purchased a new woodworking machine for making mortice and tennon joints and planing timber. The machine was made in China and came from India. I can't get help from the vendor, so am working through this myself. There is no manual although with the exception of the wiring, it is extremely robust and appears well made. Built by blacksmiths comes to mind.

When it arrived I checked it over and found that there was just a two pin plug, no earth, with 1.5mm copper cable in a blue and a brown sheath. This looked like lighting cable and for a 2HP motor seemed inadequate.

When I looked inside the plastic peckerhead cover on the motor, there are two red leads and four yellow leads that go to the motor. Connecting the switch to the motor were four leads, two blue and two green and yellow (earth cable), and a green and yellow earth lead that is not connected to anything. There is no wiring diagram. The wiring was not well done with stray copper wire ends coming from connectors.

I didn't try the motor in this configuration. Rather, with a circuit tester I traced which wire went where, then put in a new 5 core cable, brown, blue, black, grey and earth from this block to the switch (and a 3 core power lead). Brown is live (one of the blue wires), blue is return and the grey and black replace the two green/yellow leads that were present.

When I turn the switch on, I get loud buzzing from the motor, but no movement. I only try it for a second or two and it doesn't trip the RCD. The motor turns freely by hand. The switch has three buttons, green, black and red. Red is obvious, but I suspect the green and black buttons are about motor speed. Again, no instructions but with the circuit tester the voltage is directed in different pathways according to which button is pressed.

I have replicated exactly the wiring I found, only with an earth, and normal coloured cables, but clearly something is wrong.

I have tried to locate a company website but failed and although I have the machine name and number, there is nothing on the internet for it. I suspect it was manufactured some time ago, although everything was wrapped in brown wax paper, protected and greased, it just looks so 1960's.

Thanks for reading, any help would be appreciated.

NW

Last edited: