Most such motors include two separate "consequent-pole" windings.

Each such winding operates by "pole-changing", and it is possible to have 2- and 4-poles in one winding and 6- and 12-poles in the other winding.

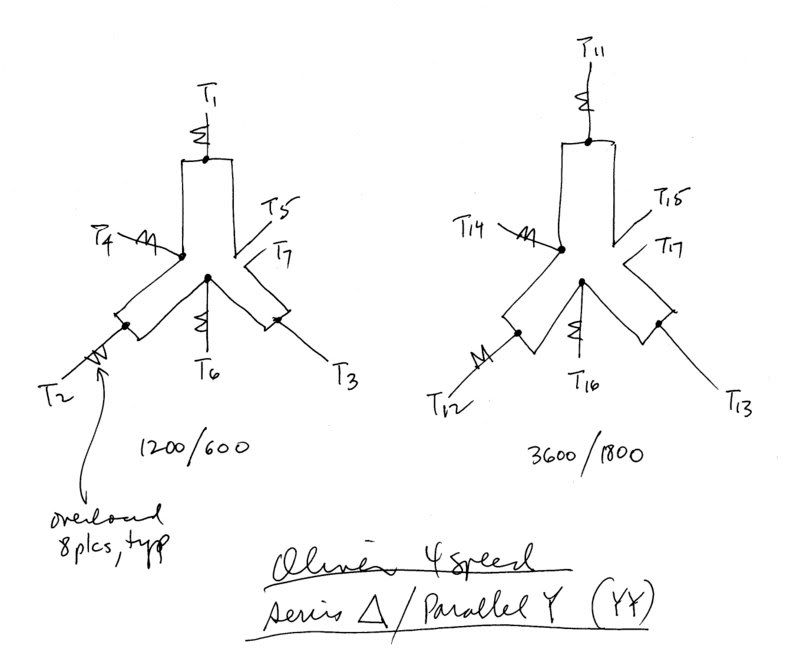

These windings operate in series ∆ and parallel Y mode.

Because the ∆ of one winding must be opened when the other winding is being used, each winding must, necessarily, have seven leads, the normal T1, T2, T3 and T4, T5, T6, but additionally T7. T7 is connected to T6 whenever that winding is being operated. Conversely, the other winding's T7 is disconnected from its T6 when that other winding is not being operated.

It is common to number these fourteen wires as T11, T12, T13, T14, T15, T16, T17, T21, T22, T23, T24, T25, T26 and T27.

Another possibility, but not in this particular case, based upon the nameplate data, is one consequent-pole winding (providing two of the speeds) and two additional Y windings (providing the two additional speeds for a total of four speeds). This requires seven wires for the consequent-pole winding and six wires for the two Y windings for a total of thirteen wires.

The Oliver patternmaker's wood lathes were famous for having four-speed motors, but in its case there were two consequent-pole windings, thereby saving slot space.

It is possible within a standard 36 slot motor to have any of the above, with the three phases evenly distributed over the 36 slots.

That previous discussion of a patternmaker's lathe can be found:

http://www.practicalmachinist.com/vb/showpost.php?p=875157&postcount=13