Family_van

Plastic

- Joined

- Mar 30, 2017

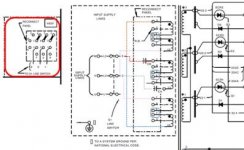

Here we go. I am working toward converting my Lincoln CV300 to 1 phase using the Haas-Kamp conversion. Thanks to all of you who have contributed their findings. I have followed the pounceatron (THANK YOU!) version CP200 diagram.

Here are the steps I have taken:

•I have hooked up the A coil on the primary side, the B coil with capacitors, and the C coil has been hooked up reverse of A.

•I have disconnected all of the windings on the primary coil that bridge the coil (original CV-300 #s 10,11,12).

•I have disconnected all the circuit boards and low voltage connections.

•I believe that the CV300 is actually Y already but I did disconnect the secondary bridge. (How do I really know if I have a y or delta without power????)

Results

When I fire it up it just trips the breaker anywhere from immediately to within 2 seconds. Not fast enough to get a voltage reading. Not sure where to go from here. Any thoughts?

I do notice that the output capacitors on the CV300 are after the SCR whereas the CP200 capacitors are before the SCR’s.

Note: I do have the welder hooked up to a 2p20 breaker but I would think where I am not drawing welding current I should be able to test it.

I have attached my modified drawing with how I have wired the CV300 and also copy of the original drawing of the transforming wiring.

Thanks!

Here are the steps I have taken:

•I have hooked up the A coil on the primary side, the B coil with capacitors, and the C coil has been hooked up reverse of A.

•I have disconnected all of the windings on the primary coil that bridge the coil (original CV-300 #s 10,11,12).

•I have disconnected all the circuit boards and low voltage connections.

•I believe that the CV300 is actually Y already but I did disconnect the secondary bridge. (How do I really know if I have a y or delta without power????)

Results

When I fire it up it just trips the breaker anywhere from immediately to within 2 seconds. Not fast enough to get a voltage reading. Not sure where to go from here. Any thoughts?

I do notice that the output capacitors on the CV300 are after the SCR whereas the CP200 capacitors are before the SCR’s.

Note: I do have the welder hooked up to a 2p20 breaker but I would think where I am not drawing welding current I should be able to test it.

I have attached my modified drawing with how I have wired the CV300 and also copy of the original drawing of the transforming wiring.

Thanks!