A friend of mine removed the motor on his Sheldon 13" lathe and unfortunately didn't completely identify the wires properly before disassembly. I know nothing about wiring motors and he doesn't know how to use the internet. So any help that can be provided would be appreciated. The motor is made by Peerless and is 220V, single phase. It has 3 wires coming out of a junction box to another smaller junction box. There are other wires in the larger junction box connected to a capacitor but they were not disturbed. The drum switch is a Furnas P2532 with 6 wires going to 6 connectors. The lower ring of the switch cylinder seems independent of the upper 2 rings. How are the 3 wires from the motor, 6 from the switch and 2 from the power source connected?

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help appreciated with Sheldon lathe wiring

- Thread starter beeser

- Start date

- Replies 12

- Views 6,913

Please get us a pic of the motor dataplate. That will be helpful.

A single phase standard induction motor must have 2 connections for the run winding, and 2 for the start winding. With 3 wires only, one of the "run" wires must be shared between the start and run windings, and the third wire is just for the start winding (and should go to the capacitor)..

The trick is to figure out which is which. Or , in this case, to tell YOU how to figure out which is which. The picture of the dataplate will help to be sure what kind of motor it is.

What does the capacitor look like? Is it a round black plastic cylinder with terminals inside of one end? Is it a metal oval or cylinder? Is it a square block (either plastic or metal)? Can you see any numbers on it, and if-so, what are they?

A single phase standard induction motor must have 2 connections for the run winding, and 2 for the start winding. With 3 wires only, one of the "run" wires must be shared between the start and run windings, and the third wire is just for the start winding (and should go to the capacitor)..

The trick is to figure out which is which. Or , in this case, to tell YOU how to figure out which is which. The picture of the dataplate will help to be sure what kind of motor it is.

What does the capacitor look like? Is it a round black plastic cylinder with terminals inside of one end? Is it a metal oval or cylinder? Is it a square block (either plastic or metal)? Can you see any numbers on it, and if-so, what are they?

The round black plastic capacitor is marked ...Please get us a pic of the motor dataplate. That will be helpful.

A single phase standard induction motor must have 2 connections for the run winding, and 2 for the start winding. With 3 wires only, one of the "run" wires must be shared between the start and run windings, and the third wire is just for the start winding (and should go to the capacitor)..

The trick is to figure out which is which. Or , in this case, to tell YOU how to figure out which is which. The picture of the dataplate will help to be sure what kind of motor it is.

What does the capacitor look like? Is it a round black plastic cylinder with terminals inside of one end? Is it a metal oval or cylinder? Is it a square block (either plastic or metal)? Can you see any numbers on it, and if-so, what are they?

Baldor

EC1645A06

645-774MSD 110 125AC

8744

It has 2 terminals on one end that already connected to wires that haven't been disturbed by the previous disassembly.

OK, that's already pretty helpful.

It confirms the motor as a regular induction motor, capacitor-start.

There are still some questions, since that capacitor rating is normally for a 120/240VAC motor. But that type motor will have 6 wires coming out of it, usually. So there are some more things to find out before the wiring can be nailed down for certain.

Which one of these junction boxes has the 230VAC power coming to it?

Is one of them attached to the motor, and if so, which one?

What color are the wires that are not connected?

If you look in whichever box is attached to the motor, does it have 6 wires going down inside the motor?

if not, how many are there?

Do the wires that go into the motor have numbers? (may be printed on the wires, or may be on tags attached to the wires)

If there are numbers, what are they?

Can we see pictures of nameplate and the inside of the boxes please?

It confirms the motor as a regular induction motor, capacitor-start.

There are still some questions, since that capacitor rating is normally for a 120/240VAC motor. But that type motor will have 6 wires coming out of it, usually. So there are some more things to find out before the wiring can be nailed down for certain.

Which one of these junction boxes has the 230VAC power coming to it?

Is one of them attached to the motor, and if so, which one?

What color are the wires that are not connected?

If you look in whichever box is attached to the motor, does it have 6 wires going down inside the motor?

if not, how many are there?

Do the wires that go into the motor have numbers? (may be printed on the wires, or may be on tags attached to the wires)

If there are numbers, what are they?

Can we see pictures of nameplate and the inside of the boxes please?

More info. needs to be gathered the next time visiting my friend but in the meantime here are answers to some of the questions above.OK, that's already pretty helpful.

It confirms the motor as a regular induction motor, capacitor-start.

There are still some questions, since that capacitor rating is normally for a 120/240VAC motor. But that type motor will have 6 wires coming out of it, usually. So there are some more things to find out before the wiring can be nailed down for certain.

Which one of these junction boxes has the 230VAC power coming to it?

Is one of them attached to the motor, and if so, which one?

What color are the wires that are not connected?

If you look in whichever box is attached to the motor, does it have 6 wires going down inside the motor?

if not, how many are there?

Do the wires that go into the motor have numbers? (may be printed on the wires, or may be on tags attached to the wires)

If there are numbers, what are they?

Can we see pictures of nameplate and the inside of the boxes please?

A larger box directly connected and seemingly part of the motor contains the capacitor and all of the wires coming out of the motor body. I don't know how many wires there are total and will check later but 3 black wires come of this box and go to a smaller attached box. These wires are labeled C1, T1 and T4. The 6 wires coming out of the drum switch and into the small box are not labeled but 3 of them are green and other 3 are black. The 3 wires coming from the power source also go to this small box. One of these wires has a round connector on it and is obviously used for ground.

Here are answers to the remaining questions.

There are 6 wires coming out of the motor. As mentioned before 3 wires marked T1, T4 and C1 go directly to the small attached junction box. The other three wires marked T2, T3 and an unmarked one go to the capacitor. T2 and T3 are tied together with one of these marked C2 going to the capacitor. The unmarked wire alone goes to the other connection on the capacitor. All of the wires from the drum switch are unmarked but three are green and 3 are black.

Here are pictures of the Peerless motor data plate, large box on motor and small attached box.

There are 6 wires coming out of the motor. As mentioned before 3 wires marked T1, T4 and C1 go directly to the small attached junction box. The other three wires marked T2, T3 and an unmarked one go to the capacitor. T2 and T3 are tied together with one of these marked C2 going to the capacitor. The unmarked wire alone goes to the other connection on the capacitor. All of the wires from the drum switch are unmarked but three are green and 3 are black.

Here are pictures of the Peerless motor data plate, large box on motor and small attached box.

Heh... the nameplate pic does not allow reading any of the information..... unfortunately not very helpful. But the motor is 6 lead, which means 2 run windings for 120V and one winding for start, also 120V. the two 120V run windings are in series for 240V. Likely that part is actually already correct, if it was already set up for reversing, and was working before taken apart.

The P2532 switch I am not sure about. I may have one like it. Those switches vary in how they work inside, so instructions also vary and I don't want to foul you up. A search on the model number of the switch gave nothing directly relating.

The switch, if you remove the cover, often has the wiring diagram on the inside of the cover.

I'll look around

The P2532 switch I am not sure about. I may have one like it. Those switches vary in how they work inside, so instructions also vary and I don't want to foul you up. A search on the model number of the switch gave nothing directly relating.

The switch, if you remove the cover, often has the wiring diagram on the inside of the cover.

I'll look around

Heh... the nameplate pic does not allow reading any of the information..... unfortunately not very helpful. But the motor is 6 lead, which means 2 run windings for 120V and one winding for start, also 120V. the two 120V run windings are in series for 240V. Likely that part is actually already correct, if it was already set up for reversing, and was working before taken apart.

The P2532 switch I am not sure about. I may have one like it. Those switches vary in how they work inside, so instructions also vary and I don't want to foul you up. A search on the model number of the switch gave nothing directly relating.

The switch, if you remove the cover, often has the wiring diagram on the inside of the cover.

I'll look around

Sorry about the motor nameplate not being readable. It was installed with the nameplate facing down but most of the information was scuffed up anyway. The motor ran fine before it was removed to replace an internal part and it was definitely wired for 220V single phase.

I realize that some of these same switches have diagrams on the back of the covers but this one did not. It had paper covering the inside but was oil soaked and didn't appear to have any writing on it or was totally unreadable. However, looking at the contacts and overall structure of the switch it's easy to see there are 3 rows of contacts on each side of it for a total of 6 contacts. The lower tier of 2 operate independently from those above and clearly makes a connection in either the forward or reverse positions and disconnects when in the off position. The 4 upper contacts are bridged in a way I've seen in some diagrams for drum switches. I hope this helps.

Thanks for the help so far!

rons

Diamond

- Joined

- Mar 5, 2009

- Location

- California, USA

If your camera has a adjustable f-stop set it to the lowest number to get a broader depth of field.

If not then place a mirror on the horizontal next to the nameplate and read the information. Those

numbers are stamped into the aluminium and you probably can read it even if the black anodize has been worn off.

Here's another pic using the mirror suggestion. The high voltage wiring diagram shows that the T1 & C1 leads are tied together and connected to one of the 120V power source wires. The T4 lead is connected to the other 120V power source wire. T2, T3 & C2 apparently go the capacitor as mentioned before.

Also, here is a pic of the Furnas drum switch. The lower tier of contacts is independent of the upper two. Wiring going to the contacts from top to bottom are ..

Green Black

Black Green

Green Black

Although not very readable. The nameplate shows 1 HP, single phase and 1725 rpm. I can't read much else beyond that.

Also, here is a pic of the Furnas drum switch. The lower tier of contacts is independent of the upper two. Wiring going to the contacts from top to bottom are ..

Green Black

Black Green

Green Black

Although not very readable. The nameplate shows 1 HP, single phase and 1725 rpm. I can't read much else beyond that.

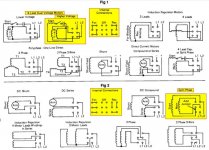

1Φ Dual Voltage Reversing Drum Switch Connections

Beeser,

Have a look at this drawing, should be similar to what you have. Study your drum switch contacts and see if they match the drawing as there are several styles. If the switch is the same then the drawing should match up with the exception of your C1, & C2 leads. These would correspond to the T5 & T8 leads in the drawing. These two are for the start winding, swapping them around will change the direction of rotation.

Looking back at the history, this was the motor that needed the start switch correct? Did the Torq people provide what you needed?

http://www.practicalmachinist.com/vb/transformers-phase-converters-and-vfd/repair-old-peerless-motor-pics-309683/

SAF Ω

Beeser,

Have a look at this drawing, should be similar to what you have. Study your drum switch contacts and see if they match the drawing as there are several styles. If the switch is the same then the drawing should match up with the exception of your C1, & C2 leads. These would correspond to the T5 & T8 leads in the drawing. These two are for the start winding, swapping them around will change the direction of rotation.

Looking back at the history, this was the motor that needed the start switch correct? Did the Torq people provide what you needed?

http://www.practicalmachinist.com/vb/transformers-phase-converters-and-vfd/repair-old-peerless-motor-pics-309683/

SAF Ω

Beeser,

Have a look at this drawing, should be similar to what you have. Study your drum switch contacts and see if they match the drawing as there are several styles. If the switch is the same then the drawing should match up with the exception of your C1, & C2 leads. These would correspond to the T5 & T8 leads in the drawing. These two are for the start winding, swapping them around will change the direction of rotation.

View attachment 170401

Looking back at the history, this was the motor that needed the start switch correct? Did the Torq people provide what you needed?

http://www.practicalmachinist.com/vb/transformers-phase-converters-and-vfd/repair-old-peerless-motor-pics-309683/

SAF Ω

What about the one point on the switch (upper left) that is not connected?

Yes, this is the motor that needed the start switch. My friend ordered one from the folks at Torq and with a little modification to the mounting made it work, at least he thinks so. Obviously he hasn't had the motor running yet.

Last edited:

What about the one point on the switch (upper left) that is not connected?

Yes, this is the motor that needed the start switch. My friend ordered one from the folks at Torq and with a little modification to the mounting made it work, at least he thinks so. Obviously he hasn't had the motor running yet.

If it were me, I would remove the motor and bench test it first, without the drum switch, to see if it even works, before spending more resources trying to figure out the drum switch and wiring connections. Looking back at the start switch thread, it was badly worn, and so must the centrifugal actuator part. On top of that you mentioned that the new stationary switch needed to be modified to fit.These thing should be sorted and tested before installing the motor in the machine.

Once you can prove that the motor is functional, then re-install it and orient it, so that the label can be seen. The tag has a connection diagram on it at the bottom, that should be visible, and will also tell you how to connect it it for the bench test. If the motor doesn't start on the bench there is not much use in sorting out the rest, as the motor would need replacing with something that works first, and a new motor will likely be somewhat different in it's connections

If that part gets sorted, then we can move on to the drum switch and wiring.

The drum switch is something you must sort out, to figure out what style you have. The part # you gave didn't return any good results on a search. The picture you provided didn't provide enough detail to see what style it is.

As I mentioned earlier there are many styles that were made. If I recall correctly Furnace made 3 styles that were different. Here is a connection diagram of the 2 most popular styles from Furnace

You study the diagrams and switch and tell us which one you have, then well have a much better idea of which way it needs to be connected. Maybe it's neither of these two, only you can tell.

SAF Ω

Similar threads

- Replies

- 10

- Views

- 983

- Replies

- 1

- Views

- 321

- Replies

- 9

- Views

- 903