Cannonmn,

From what you posted, it appears that your grinder is a 2HP 3Φ 220/440 Motor.

Currently setup for 440V operation.

Clues of how to tell:

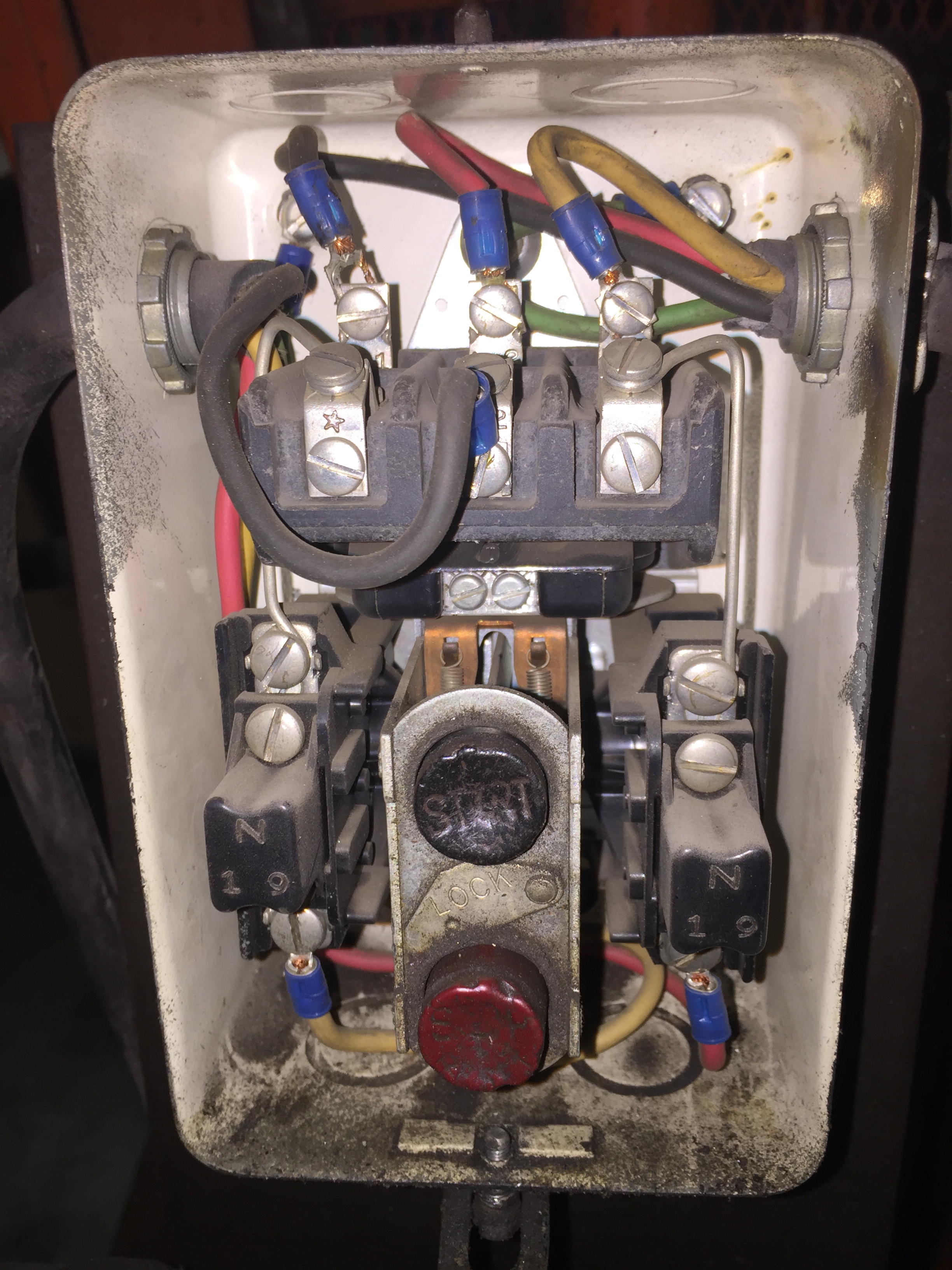

The manual motor starter is rated for 2HP max @ 220V or 440V, on the label

The Existing N19 Heater elements are rated at 3.26A

The NEC full load current for a 2HP motor is 220/440V 6.8/3.4A

To operate that motor at 208V will require 7.5A and heater size N28 (good for 7.63A)

To change the motor winding connections for low voltage operation (220), Reattach the grinder to the pedestal.

Lay the unit down, and reconnect the 9 motor leads inside the pedestal, to match the diagram for low voltage.

The 9 leads are spliced to the 3 leads, L1,L2.L3 entering the manual starter.

DO NOT operate the motor with the current heaters installed, even momentarily. Doing so will damage the heater elements in short order. And worse it will overheat the heater relays and cause them to be uncalibrated or fail to function properly. That's an old manual starter, but heavy duty. If you get the correct heaters for your voltage, it will likely last as long as you.

SAF Ω

*Jaref ought to be along shortly to tell you to junk that old starter, and put something more modern on there that is supported and compliant with today's standards (one with 3 overload relays). But I think it goes with the grinder well. Worked for the last 70+ years, why change now? Personally, I'd rather invest for some grease in the dried out bearings, rather than a new controller.