Lost Pup

Aluminum

- Joined

- Feb 19, 2010

- Location

- Bensalem PA

I started out doing a rebuild of an old Logan shaper and I needed a motor to finalize the project. My SB 10K lathe had/has a 1/2 HP 1750 rpm single phase motor so I thought what a perfect motor for the shaper project. I was looking for a chance to upgrade the SB Lathe to a VFD 3 phase setup.

Here is the cost so far and a few pics to get started:

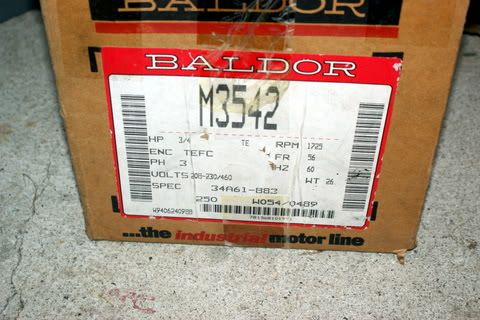

$69.89 Delivered : New Baldor 3 Phase 3/4 HP M3542 Motor w/ 56 Frame (Auction)

$24.90 Delivered : Hoffman Electrical Box 12"x10"x6" (Auction)

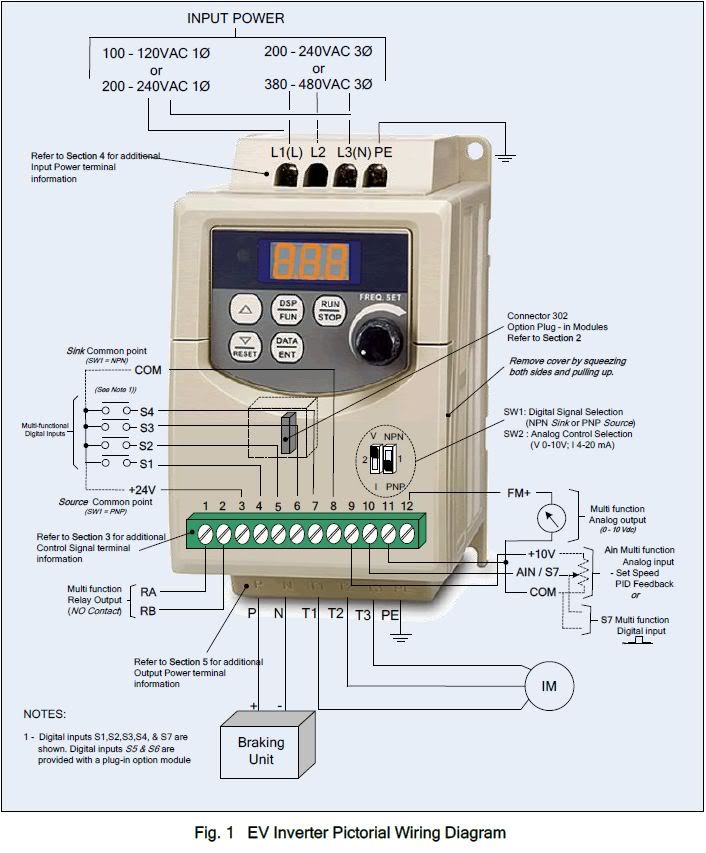

$145.71 Model JNEV-101-H1, Single Phase Input ONLY, Three Phase Output ( Dealers Electric )

Here is the cost so far and a few pics to get started:

$69.89 Delivered : New Baldor 3 Phase 3/4 HP M3542 Motor w/ 56 Frame (Auction)

$24.90 Delivered : Hoffman Electrical Box 12"x10"x6" (Auction)

$145.71 Model JNEV-101-H1, Single Phase Input ONLY, Three Phase Output ( Dealers Electric )

Last edited: