I've been reading all the great info about the haas/kamp single phase conversions on the site.I picked up a lincoln dc400 and a ln-10 feeder for 300 bucks and would sure like to ba able to run it on single phase instead of building a rpc.

So far I have tested the machine using a Phase A Matic SPC just to verify that things energize and seem to operate controls ect. I didnt weld with it hooked up to the SPC, but the cooling fan and the wire feeder seem to work fine after i swapped the line voltage taps on the control transformer and made the "A" phase the phantom leg, and "B" and "C" phases line voltage.

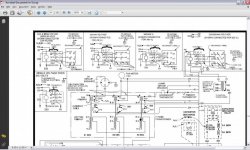

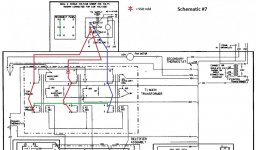

After looking at the diagrams for the machine and the actual wiring I think that the X1 main transformer coil is the one that would be used on the phantom leg. This particular machine has 9 leads coming to the reconnect panel from the actual welder coils.

I'm somewhat confused about how to retap these leads and add the caps.

I did read a post about a cv 400 conversion, but it was kind of convoluted as to how it all ended up working, no disrespect meant.

Any help would be great

, thanks.

So far I have tested the machine using a Phase A Matic SPC just to verify that things energize and seem to operate controls ect. I didnt weld with it hooked up to the SPC, but the cooling fan and the wire feeder seem to work fine after i swapped the line voltage taps on the control transformer and made the "A" phase the phantom leg, and "B" and "C" phases line voltage.

After looking at the diagrams for the machine and the actual wiring I think that the X1 main transformer coil is the one that would be used on the phantom leg. This particular machine has 9 leads coming to the reconnect panel from the actual welder coils.

I'm somewhat confused about how to retap these leads and add the caps.

I did read a post about a cv 400 conversion, but it was kind of convoluted as to how it all ended up working, no disrespect meant.

Any help would be great

, thanks.

Last edited: