bearanddragon

Plastic

- Joined

- Apr 27, 2017

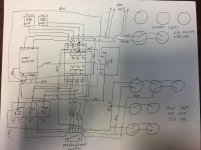

I recently acquired an American Rotary ADX25 for parts or repair and I plan on repairing it to power my laser. The panel housing was pretty banged up and the internal components were knocked around pretty good. The guy I bought it from is trustworthy (I think)and said its complete and that the damage is just cosmetic. That being said, most the wiring on the caps was removed or pulled off when the damage occurred. I want to get this thing up and running however I can't seem to find any pictures of an ADX25 internals online anywhere. I was hoping that if someone on the forum had one and could snap a picture of its internals for me it'd be greatly appreciated. Apparently it's something that American Rotary won't release.

Thanks!

Thanks!