I recently bought a Tree J325 CNC knee mill, which has a motor capable of 5HP for short periods, and 3HP continuous. Part of the deal was a 10HP RPC. My current power setup has a 3HP RPC, put together from a Phase-a-Matic 1-3HP heavy-duty static converter and a 3HP idler motor. It has been working fine, for 2HP lathe, and a couple of BPorts, occasionally with 2 machines running at once.

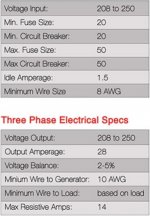

The 10HP RPC has a mfr's label that states "10 HP 50 amps", and little else in the way of specification. It was built by Anderson Converter in Arizona, who I think may be out of business. My question is regarding the input to the converter, and what the resultant output is in terms of current. I had planned to provide a 30A circuit for the "new" RPC, with 30A 2-pole breaker on my single phase 220 sub-panel, and appropriate wire sizing for 30A. The Tree mill says it wants a 30A 3-phase circuit.

So, is it realistic that a 30A single-phase 220 supply to the 10HP RPC results in having 50A available as output into the 3-phase distribution circuit?

I seriously doubt that I will ever be requiring the full output of the RPC capability, but I want to make sure I have breaker and wiring set up correctly. It does involve some re-wiring in my existing power arrangement, so I hope to get it done right the first time, and not end up with frequent breaker trips, or (worse) over-heated wiring.

The 10HP RPC has a mfr's label that states "10 HP 50 amps", and little else in the way of specification. It was built by Anderson Converter in Arizona, who I think may be out of business. My question is regarding the input to the converter, and what the resultant output is in terms of current. I had planned to provide a 30A circuit for the "new" RPC, with 30A 2-pole breaker on my single phase 220 sub-panel, and appropriate wire sizing for 30A. The Tree mill says it wants a 30A 3-phase circuit.

So, is it realistic that a 30A single-phase 220 supply to the 10HP RPC results in having 50A available as output into the 3-phase distribution circuit?

I seriously doubt that I will ever be requiring the full output of the RPC capability, but I want to make sure I have breaker and wiring set up correctly. It does involve some re-wiring in my existing power arrangement, so I hope to get it done right the first time, and not end up with frequent breaker trips, or (worse) over-heated wiring.