I've enjoyed absorbing as much info as possible in the past few weeks and learning more about motor controls and rotary phase converters has been fascinating, but I wanted to get a sanity check from people smarter than me on these topic before throwing more money at this project.

What I have:

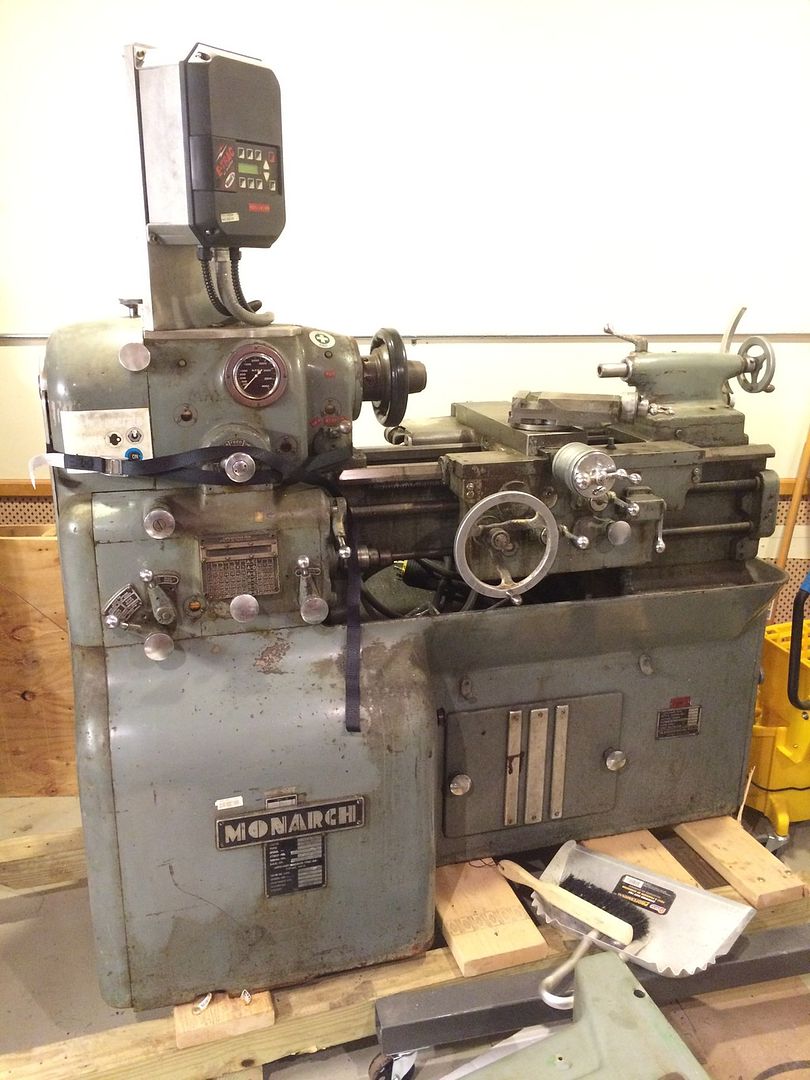

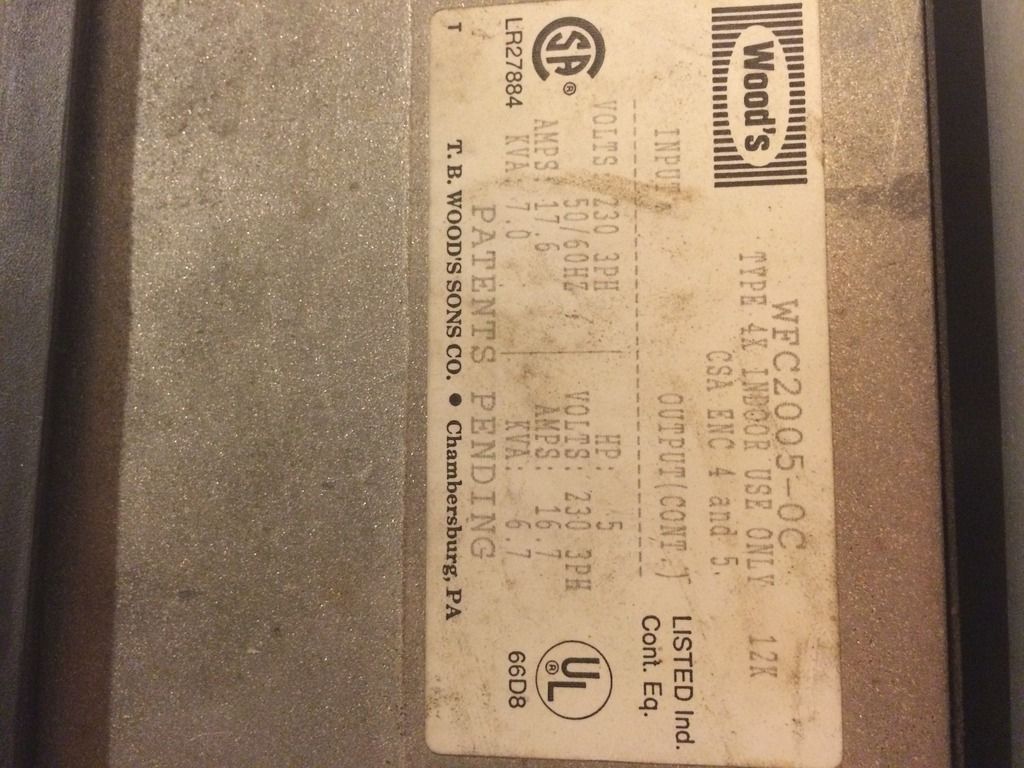

1. Monarch 10EE with inverter duty 5 hp motor driven by 220 3Ph input 5 hp TB Wood's E-Trac AC Inverter

2. Cincinnati Toolmaster 3 hp 3Ph motor

3. 20" bandsaw 1 hp 3Ph motor

What I did not want to do:

-Put new VFD's on all 3 machines and run off 110V.

My goal:

-Make or buy a RPC that will supply 3Ph for all machines, including the clean power required to feed the existing VFD on the lathe.

I have a 10 hp 3Ph motor for the RPC. I've scoured over the different designs and feel confident I could copy the Fitch plans to make a RPC that would not burn the house down.

My questions:

1. Make or buy?

a. American Rotarty 5 hp panel only is about $280. Has everything but the motor. Looking at Fitch components on Grainger, cost for components without assembly would be 2x to 3x this. I realize many guys have scrounged the parts for next to nothing. I've spent the winter re-habbing this mill and want to spend time cutting chips more than I want to scour Ebay for every component.

b. The off-the-shelf AR panel would be fine for the mill and saw, but may not be balanced tightly enough for the lathe VFD. It seems I could tie in some more run caps to balance tighter to my motor, if I need to. Are there any issues with this- besides blowing away any AR warranty?

c. In general, what benefit is there to me building my own, besides the value of the learning experience? From what I see, it's going to cost me significantly more to build it myself, unless I spend quite a bit of time scrounging for parts, and then I have the hours of working my way through assembly.

2. If I buy the AR panel, would you recommend testing the balance first or just try to power the VFD and "see what happens".

3. If I do need to change run capacitance, should I balance it for the 5 hp lathe motor? I've seen some guys balance the voltages based on a motor in the middle of the range of motors to be powered with the RPC.

I feel fortunate to have access to this knowledge base. I'd appreciate any comments/recommendations. Another fallback option is to get the AR panel, use it to power everything without a VFD and if it isn't balanced well enough for the VFD start saving for a 10 hp VFD to debate and use for the lathe.

What I have:

1. Monarch 10EE with inverter duty 5 hp motor driven by 220 3Ph input 5 hp TB Wood's E-Trac AC Inverter

2. Cincinnati Toolmaster 3 hp 3Ph motor

3. 20" bandsaw 1 hp 3Ph motor

What I did not want to do:

-Put new VFD's on all 3 machines and run off 110V.

My goal:

-Make or buy a RPC that will supply 3Ph for all machines, including the clean power required to feed the existing VFD on the lathe.

I have a 10 hp 3Ph motor for the RPC. I've scoured over the different designs and feel confident I could copy the Fitch plans to make a RPC that would not burn the house down.

My questions:

1. Make or buy?

a. American Rotarty 5 hp panel only is about $280. Has everything but the motor. Looking at Fitch components on Grainger, cost for components without assembly would be 2x to 3x this. I realize many guys have scrounged the parts for next to nothing. I've spent the winter re-habbing this mill and want to spend time cutting chips more than I want to scour Ebay for every component.

b. The off-the-shelf AR panel would be fine for the mill and saw, but may not be balanced tightly enough for the lathe VFD. It seems I could tie in some more run caps to balance tighter to my motor, if I need to. Are there any issues with this- besides blowing away any AR warranty?

c. In general, what benefit is there to me building my own, besides the value of the learning experience? From what I see, it's going to cost me significantly more to build it myself, unless I spend quite a bit of time scrounging for parts, and then I have the hours of working my way through assembly.

2. If I buy the AR panel, would you recommend testing the balance first or just try to power the VFD and "see what happens".

3. If I do need to change run capacitance, should I balance it for the 5 hp lathe motor? I've seen some guys balance the voltages based on a motor in the middle of the range of motors to be powered with the RPC.

I feel fortunate to have access to this knowledge base. I'd appreciate any comments/recommendations. Another fallback option is to get the AR panel, use it to power everything without a VFD and if it isn't balanced well enough for the VFD start saving for a 10 hp VFD to debate and use for the lathe.