Steve@610Euro

Plastic

- Joined

- Oct 6, 2010

- Location

- PA, USA

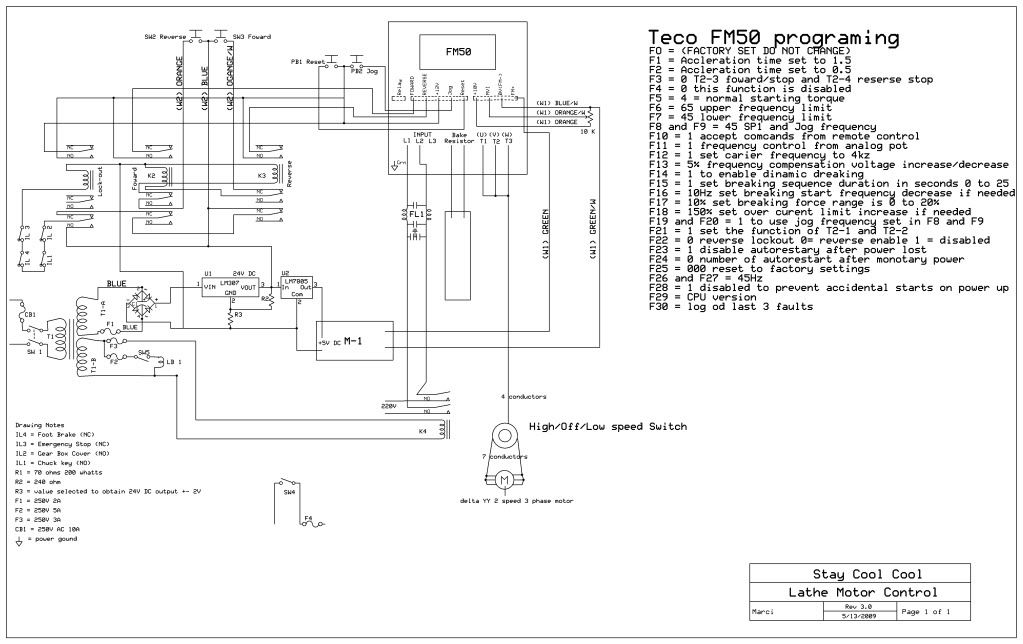

while reading the manual and searching the internet i started to really question how im wiring in my VFD's.

ill start off with the lathe. 3ph 3 hp motor. the vfd is a 3hp.

that 1 2 F and 1 2 R switch box is wired directly to that start/stop switch, which i just thought id wire to the vfd. but now imthinking thats completely wrong.

im thinking i need to remove that start/stop box and wire the 1 2 f/1 2 r box directly to the vfd and use a seperate switch to turn the vfd fwd/rev. but then how will that work ? ill have a fwd/rev switch on the vfd and on that second control box ? wont they clash together ?

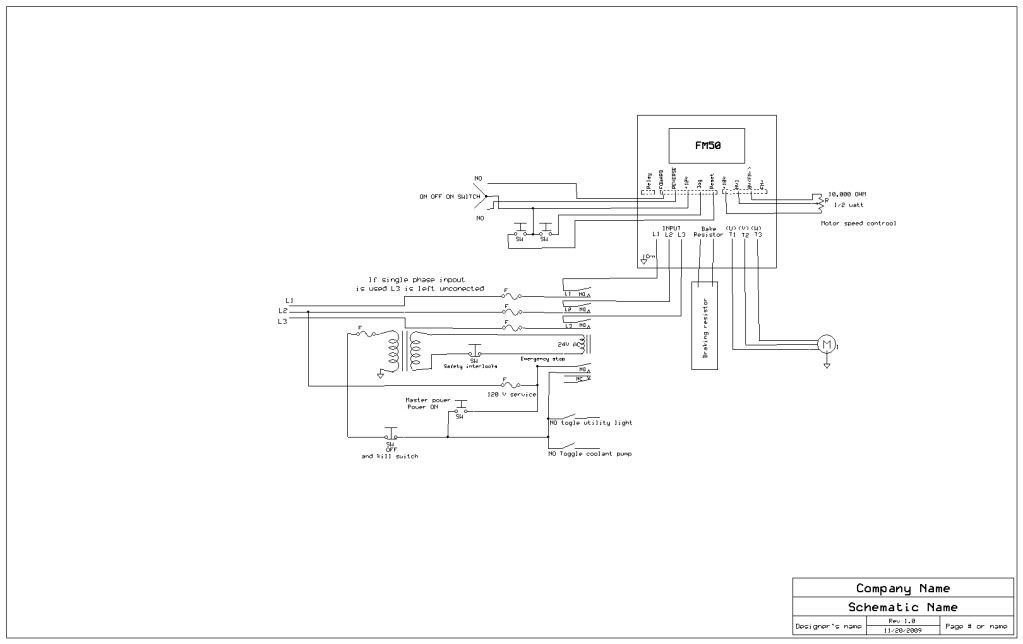

second is my 1.5hp 3ph bridgeport mill. the vfd is a 2hp.

i dont have the switch box bolted to the motor but just look past that. for the mill do i just skip the switch box entirely and run a simple fwd/rev switch on the vfd ?

please specify which machine you are talking about wehen giving help. also what switches do you guys recommend i use to control the vfd's ? links to specific switches would be best.

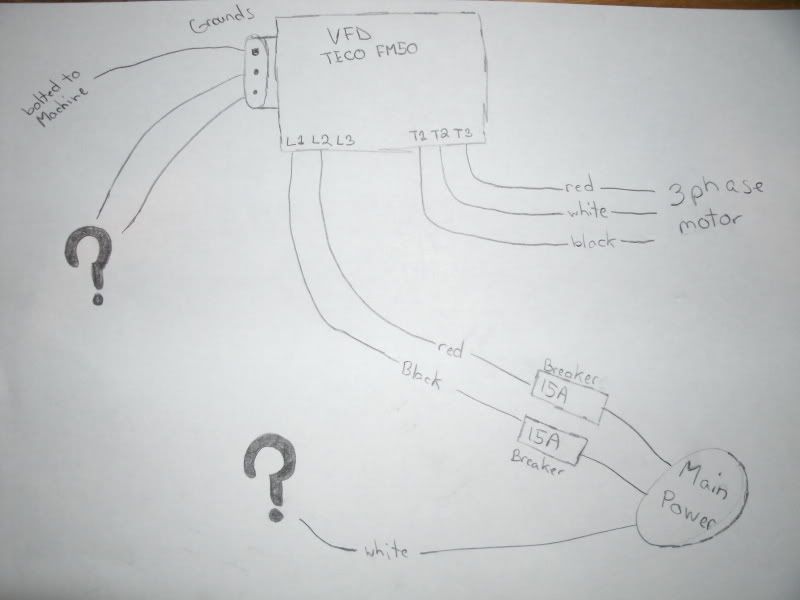

lastly, where do i run the grounds from the vfd to ? do i just ground them to the steel of the machine ?

ill start off with the lathe. 3ph 3 hp motor. the vfd is a 3hp.

that 1 2 F and 1 2 R switch box is wired directly to that start/stop switch, which i just thought id wire to the vfd. but now imthinking thats completely wrong.

im thinking i need to remove that start/stop box and wire the 1 2 f/1 2 r box directly to the vfd and use a seperate switch to turn the vfd fwd/rev. but then how will that work ? ill have a fwd/rev switch on the vfd and on that second control box ? wont they clash together ?

second is my 1.5hp 3ph bridgeport mill. the vfd is a 2hp.

i dont have the switch box bolted to the motor but just look past that. for the mill do i just skip the switch box entirely and run a simple fwd/rev switch on the vfd ?

please specify which machine you are talking about wehen giving help. also what switches do you guys recommend i use to control the vfd's ? links to specific switches would be best.

lastly, where do i run the grounds from the vfd to ? do i just ground them to the steel of the machine ?