Jim Fitz-Gerald

Aluminum

- Joined

- Dec 10, 2010

- Location

- Schuyler, VA USA

Hi All,

I have posted in the general section, but likely should have started here for direct advice.

I have a Barber Coleman 1610Tx42 lathe, 1961. It has an old drive with thyratrons in it. It is quite a piece. I was told the drive was bad, the motor is good. I have no proof of either, this is from the former owner who is trustworthy. Not sure what to do here but I would like to see what my options are. I have a couple of other smaller machines that will be using 220 3 PH so I am considering buying a RPC and a drive for the Coleman, just not sure which one or the best route. I am just completing my shop, the power will be on within 10 days: 220v single phase, 200A.

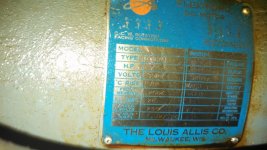

The motor specs are:

240 Volt, FL amps 28, field volts 240,

Feld amps: 1.32 / 0.26.

C Rise: 70

Frame: B286A

MFR: The Louis Allis Co. Milwaukee, Wisconsin

I have seen comments regarding the VFD but I am not sure they would be right for this machine. Galco, BICL and American Rotary are referenced quite a bit here.

This looks like a great old machine so I am hoping to get it going. Any advice would be appreciated.

Thanks,

Jim

I have posted in the general section, but likely should have started here for direct advice.

I have a Barber Coleman 1610Tx42 lathe, 1961. It has an old drive with thyratrons in it. It is quite a piece. I was told the drive was bad, the motor is good. I have no proof of either, this is from the former owner who is trustworthy. Not sure what to do here but I would like to see what my options are. I have a couple of other smaller machines that will be using 220 3 PH so I am considering buying a RPC and a drive for the Coleman, just not sure which one or the best route. I am just completing my shop, the power will be on within 10 days: 220v single phase, 200A.

The motor specs are:

240 Volt, FL amps 28, field volts 240,

Feld amps: 1.32 / 0.26.

C Rise: 70

Frame: B286A

MFR: The Louis Allis Co. Milwaukee, Wisconsin

I have seen comments regarding the VFD but I am not sure they would be right for this machine. Galco, BICL and American Rotary are referenced quite a bit here.

This looks like a great old machine so I am hoping to get it going. Any advice would be appreciated.

Thanks,

Jim