Bread

Aluminum

- Joined

- Oct 4, 2013

- Location

- Ballard, WA

So, hi

I'm finally setting up my home shop with a mill and lathe, both of which are/were wired for 440v service. To bring you up to speed, I installed a 100amp subpanel in my garage and have already wired the building, and ran an outlet to my Kay RPC (pictured). The nameplate rating might look underpowered, but according to Kay, this RPC will run and start a 1.5 to 7.5hp motor. Built this little cart to get it low enough to roll under my lathe. RPC runs great, and I wired my Bridgeport to 220v no problem as the diagram is right on the motor. Runs awesome.

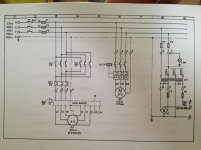

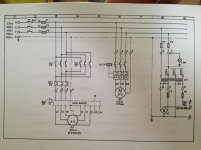

So onto the lathe. The motor is complex (to me). It's a two speed motor, which also runs forward and reverse. I've attached a picture of the tag on the electrical cabinet which shows that it's designed to run on 220v. Also attached in this post are the two wiring diagrams from the owners manual.

I'm finally setting up my home shop with a mill and lathe, both of which are/were wired for 440v service. To bring you up to speed, I installed a 100amp subpanel in my garage and have already wired the building, and ran an outlet to my Kay RPC (pictured). The nameplate rating might look underpowered, but according to Kay, this RPC will run and start a 1.5 to 7.5hp motor. Built this little cart to get it low enough to roll under my lathe. RPC runs great, and I wired my Bridgeport to 220v no problem as the diagram is right on the motor. Runs awesome.

So onto the lathe. The motor is complex (to me). It's a two speed motor, which also runs forward and reverse. I've attached a picture of the tag on the electrical cabinet which shows that it's designed to run on 220v. Also attached in this post are the two wiring diagrams from the owners manual.