Denny Graham

Aluminum

- Joined

- Sep 1, 2004

- Location

- Sandwich, IL

Well I'm new here and I've been reading and downloading for the last three weeks. Soooo, I think I know just about enough to ask a few questions now, without sounding like to much of a dutz!

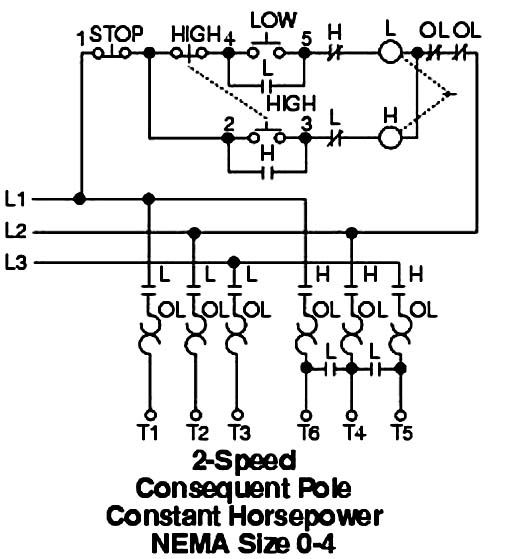

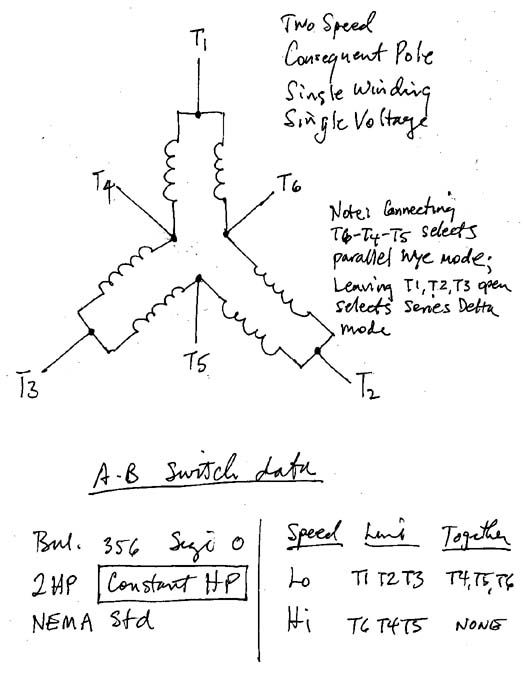

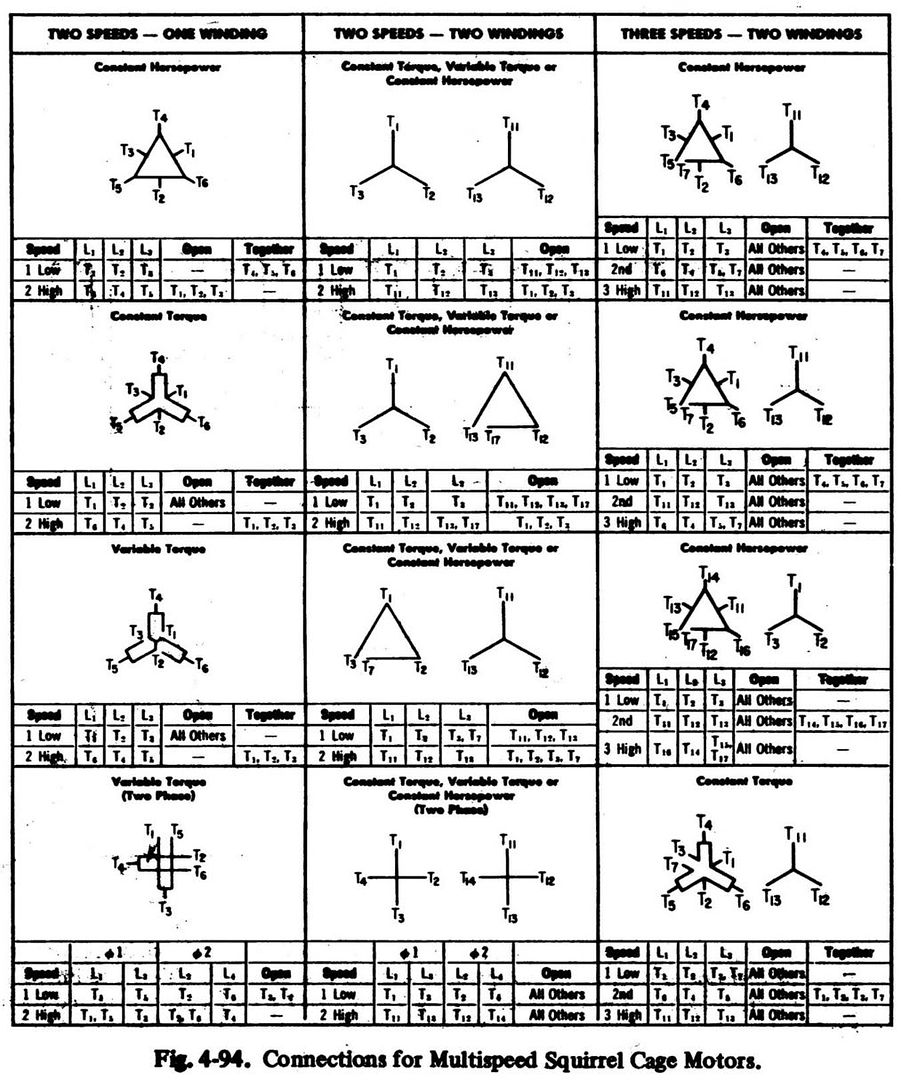

I would like to use a big old finned, cast iron, Peerless 2hp, 3ph, 220v, 5.2/6.2a totaly enclosed motor off of a spindle sander as an RPC. This is a two speed motor (3500/1750rpm) and was wired to a drum switch for Lo/Hi. The motor has two sets of wires that ran to the switch. Set1= T1,T2,T3. Set2= T4,T5,T6. I'm assuming that one set is for Lo speed and the other set is for Hi speed. I have no wiring diagram to referance to so I'm not sure what's going on with the coils.

My question is, can I use this motor for an idler and would I just use the 1750rpm set i.e. T1,2,3 for my converter? If so would I just tie T4,5,6 togeather? I am reading 3.6 ohm between any pair of T1,T2,T3. Also 3.6 ohm between any pair of T4,T5,T6. There is also some sort of internal connection between set1 and set2 as I get continuity between the two sets also.

I will probably use this RPC for a 1hp Bridgeport mill. After I play around with this ($10) 2hp motor and get a better feel for RPC's and ballancing, I will attack a (much more expensive)7.5hp 1740rpm RPC. I bought the 7.5hp idler to build a larger unit for my 2hp mill and any other 3ph equipment I may add to my shop.

Thanks in advance guys.

Denny Graham

Sandwich, IL

I would like to use a big old finned, cast iron, Peerless 2hp, 3ph, 220v, 5.2/6.2a totaly enclosed motor off of a spindle sander as an RPC. This is a two speed motor (3500/1750rpm) and was wired to a drum switch for Lo/Hi. The motor has two sets of wires that ran to the switch. Set1= T1,T2,T3. Set2= T4,T5,T6. I'm assuming that one set is for Lo speed and the other set is for Hi speed. I have no wiring diagram to referance to so I'm not sure what's going on with the coils.

My question is, can I use this motor for an idler and would I just use the 1750rpm set i.e. T1,2,3 for my converter? If so would I just tie T4,5,6 togeather? I am reading 3.6 ohm between any pair of T1,T2,T3. Also 3.6 ohm between any pair of T4,T5,T6. There is also some sort of internal connection between set1 and set2 as I get continuity between the two sets also.

I will probably use this RPC for a 1hp Bridgeport mill. After I play around with this ($10) 2hp motor and get a better feel for RPC's and ballancing, I will attack a (much more expensive)7.5hp 1740rpm RPC. I bought the 7.5hp idler to build a larger unit for my 2hp mill and any other 3ph equipment I may add to my shop.

Thanks in advance guys.

Denny Graham

Sandwich, IL