Spud

Diamond

- Joined

- Jan 12, 2006

- Location

- Brookfield, Wisconsin

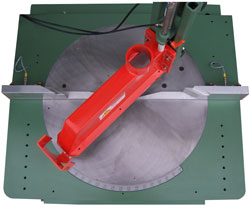

So I see lots of cabinet, woodworking shops use UpCut saws, especially Whirlwind brand.

So what's special about it, versus a manual or automatic pull down chop saw (like an Omga)?

So what's special about it, versus a manual or automatic pull down chop saw (like an Omga)?