Sweet Dreamer

Aluminum

- Joined

- May 26, 2013

- Location

- Pennsylvania

Have you found out when it was made? John O. should be able to look up the serial number for you.

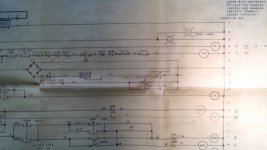

There is some original paper work in the electrical box. Full schematics that are clearly very old paper. They are dated 1953, 1958, and 1959. So I'm guessing this lathe was made in the late 50's early 60's.

Serial number is 1561063

I've done several searches on the Internet for Warner & Swasey serial numbers and all I find are reports that they weren't kept track of, or there is no data base for Warner & Swasey serial numbers. So if John O. can look this up I would love to know where he found the data base.

There's a huge supply of the machines, and no one wants them. So they either get sold to guys like you or me for pennies on the dollar, or they get scrapped.

Well I have no regrets about buying mine yet(fingers crossed on that one). I'm glad to have saved it from the scrap yard. I almost bought a second one at a similar price just to have spare parts. It's gone now. Don't know if they sold it or scraped it. The main reason I didn't buy it is because I only have one trailer. LOL

In any case, about the only operation this lathe can't do relative to an engine lathe is threading with a quick-change gearbox. That's really about the only feature it's seriously missing. Other things like not having a compound rest are no big problem. You could easily add a compound rest.

I've been reading though a book entitled "How to get the most from your Warner & Sawsey Turret Lathe" It offers a lot of hints on how to do specific operation including turning tapers. In fact using the method they suggest you could actually make fixtures to cut fancy profiles.

I mean, it can do a lot as a job-shop lathe why more machinists aren't interested in these I really can't understand. But good for me that they aren't, otherwise it would have never sold this cheap.

In fact, I already have some "milling" operations I would like to use this lathe for. I say, "milling" because the operation involves placing the cutter in the headstock and the workpiece on the cross slide. This obviously has great limitations relative to a regular milling machine. But it can do two operations really well:

1. As long as you only need to move the workpiece directly back and forth (like milling long slots or fly cutting a surface, it will work great. You just won't be able to raise or lower the work piece easily without building a special table for that.

2. Used with a dividing head on the cross slide it can also be used to cut gears, sprockets, or other operations where the dividing head is used to turn the part at precise angles or degrees.

I can see myself using this option quite often actually. So this will double for me as a fairly useful milling machine. Albeit somewhat limited in what it can actually do as mill.

In short, with a little imagination and some homemade fixtures I'll be able to use this machine to do quite a bit of what I would like to do. It's certainly not a machine to walk away from thinking that it's obsolete or useless. It's a powerful machine that has a lot to offer an open-minded machinist who has a working imagination.

Looking at it as "just an obsolete turret lathe that was once used for mass production" is really the wrong way to view it.

It really has a lot of potential as a useful job-shop machine.

As far as I can see, about the only thing it won't do is cut threads using the lead screw.