Peter S

Diamond

- Joined

- May 6, 2002

- Location

- Auckland, New Zealand

Sometimes your long lathe bed is still not quite long enough.

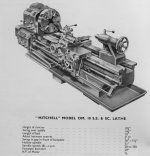

Shown here on a Mitchell lathe, the "Extenda-bed" is another great idea from.....New Zealand?

Take your gap piece and fit it to the tail end.

How do you attach it? You will have to figure that out yourself, e.g. do you ever want to remove it?

While we are thinking about lathe beds - do you ever find your bed is too long?

Stop worrying, just get out there and do it:

This old Binns & Berry in NZ was over-length and the off-cut was probably useful too:

Make it a bit shorter and you've got a lathe for the home workshop:

Shown here on a Mitchell lathe, the "Extenda-bed" is another great idea from.....New Zealand?

Take your gap piece and fit it to the tail end.

How do you attach it? You will have to figure that out yourself, e.g. do you ever want to remove it?

While we are thinking about lathe beds - do you ever find your bed is too long?

Stop worrying, just get out there and do it:

This old Binns & Berry in NZ was over-length and the off-cut was probably useful too:

Make it a bit shorter and you've got a lathe for the home workshop: