I found Kerzom's thread on 10EE sight glass 3d printing https://www.practicalmachinist.com/forum/threads/oil-level-sight-glass.389520/ , and I really liked the idea. the only problem is it doesn't look quite right once assembled.

Parts:

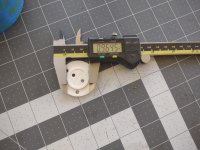

1- 23.9mm x 2mm watch crystal from allwatchparts.com (30mm will fit too, there's some slack there) https://allwatchparts.com/20mm-Flat...Crystal-170mm-350mm-01mm-increment_p_676.html $1.75 ea.

2- Square profile Buna-N -019 13/16" ID, 15/16" OD, 1/16" Cross Section https://www.mcmaster.com/4061T124/ $13 for 100

3 - white PLA 3d print filament. ( I have a Creality Ender v3 printer I got for less than $200)

4 - Files on thingaverse: https://www.thingiverse.com/thing:5522594

As you can see, the bezel is recessed. For my tastes, it is a bit too much.

Since I have tasked myself to get better at Fusion 360, I started modeling a modified version. I really liked how the original had provisions to retain the O-ring during assembly so I did the same, taking it a step farther with a groove molded in to the back side as well.

This holds the o-ring tight, have to press pretty hard to get it to insert.

After an embarrassingly numerous amount of re-designs and reprints, this is what I came up with. you can see one of my previous iterations off to the left there.

Modeled a groove on the face that can be painted for contrast if desired. Sharpie PRO marker is oil resistant. The results are a flush mount oil sight glass.

Anyone have any suggestions for improvements I'm all ears.

Cheers,

Mooserov

Parts:

1- 23.9mm x 2mm watch crystal from allwatchparts.com (30mm will fit too, there's some slack there) https://allwatchparts.com/20mm-Flat...Crystal-170mm-350mm-01mm-increment_p_676.html $1.75 ea.

2- Square profile Buna-N -019 13/16" ID, 15/16" OD, 1/16" Cross Section https://www.mcmaster.com/4061T124/ $13 for 100

3 - white PLA 3d print filament. ( I have a Creality Ender v3 printer I got for less than $200)

4 - Files on thingaverse: https://www.thingiverse.com/thing:5522594

As you can see, the bezel is recessed. For my tastes, it is a bit too much.

Since I have tasked myself to get better at Fusion 360, I started modeling a modified version. I really liked how the original had provisions to retain the O-ring during assembly so I did the same, taking it a step farther with a groove molded in to the back side as well.

This holds the o-ring tight, have to press pretty hard to get it to insert.

After an embarrassingly numerous amount of re-designs and reprints, this is what I came up with. you can see one of my previous iterations off to the left there.

Modeled a groove on the face that can be painted for contrast if desired. Sharpie PRO marker is oil resistant. The results are a flush mount oil sight glass.

Anyone have any suggestions for improvements I'm all ears.

Cheers,

Mooserov