Panza

Stainless

- Joined

- Oct 23, 2005

- Location

- Lillehammer, Norway

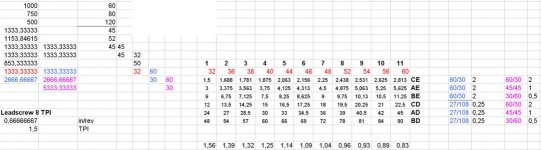

Which metric threads will an American Pacemaker cut with the appropriate gears ? Are those gears easily available anywhere ? Thread range/number.

Has anyone been to look at this one by the way ? : http://www.rdequipment.net/AmericanPacemakerEngineLathe7062249.htm

Has anyone been to look at this one by the way ? : http://www.rdequipment.net/AmericanPacemakerEngineLathe7062249.htm