Hendeyman,

Many thanks for the explanation - I'm much obliged.

Your description is clear to me, especially as I have the advantage of the 1888 drawing. For the benefit of others who might be interested in the ‘box’ within the firebox, I’ll try and describe the arrangement, having now understood it from Hendeyman‘s description.

Imagine a thick-walled cast iron box about 6" tall and 1 ft high, standing about 6" away from the tube plate. The tubular firebars, which have entered the firebox just below the firedoor, slope slightly downwards to enter the iron box near the bottom. The rear face of this box is perforated by a series of holes which will admit air, preheated by its passage through the tubes.

The firebox itself is cylindrical, thereby avoiding the need for stays. It occupies just over half the length of the boiler. 64 horizontal tubes go from the firebox to the smoke box.

Unfortunately, I wasn’t aware that there might be anything unusual about the firebox, so didn’t pay any attention, and my photos don’t show anything below the firedoor. I hope that anyone who reads this and might visit the museum will be guided to look further than I did. It’s a vain hope, as I have no evidence to suggest that any museum has benefited from a single extra visit as a result of my posts!

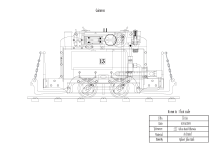

The photo above suggests that the boiler shell has a number of horizontal staybars.

Also note the small lever on the LHS. I don’t know what it's for, but I can imagine the look on the blacksmith’s face when the apprentice was sent back with the first example to have the kink put into it to clear some obstruction.

There is no room for a steam dome, steam being taken from the boiler through a long horizontal internal collector pipe placed close to the top.