How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1 - 1/4 8tpi thread drill size

- Thread starter jucasan

- Start date

- Replies 13

- Views 2,996

precisionmetal

Stainless

- Joined

- May 16, 2005

- Location

- CA

Or... the easy way: major diameter minus the pitch

That's never far off.

PM

That's never far off.

PM

DMF_TomB

Diamond

- Joined

- Dec 13, 2008

- Location

- Rochester, NY, USA

The title say it all. Need to mill a 1 - 1/4 8tpi thread in a part but can't find what is the size of the drill.

Thanks

8tpi is .125 between threads so 1.250-.125 = 1.125 tap drill i believe for roughly 75% thread

.

thats why .250-20 thread is 1/20=.050 so .250-.050=.200 tap drill for 1/4-20 you can check other sizes on any tap drill chart for example 1.000-8tpi thread is .875 tap drill

Dan from Oakland

Titanium

- Joined

- Sep 15, 2005

- Location

- Oakland, CA

I'm getting old, so I do silly things like pull out the drawer in my toolbox that has the machinery handbook in it, and open it to the tab that says "threads" on it. Sorry for the bit of sarcasm but. . . . .

8tpi is .125 between threads so 1.250-.125 = 1.125 tap drill i believe for roughly 75% thread

.

thats why .250-20 thread is 1/20=.050 so .250-.050=.200 tap drill for 1/4-20 you can check other sizes on any tap drill chart for example 1.000-8tpi thread is .875 tap drill

Thank you DMF, I must be screwing something up in the parameters of the thread. In the simulation with the 1.125 diameter the thread tool barelly scratches the surface. I guess this is something for the Fusion forum.

Thank you anyway

Thank you DMF, I must be screwing something up in the parameters of the thread. In the simulation with the 1.125 diameter the thread tool barelly scratches the surface. I guess this is something for the Fusion forum.

Thank you anyway

Good God!! That's painful.

DMF_TomB

Diamond

- Joined

- Dec 13, 2008

- Location

- Rochester, NY, USA

.Thank you DMF, I must be screwing something up in the parameters of the thread. In the simulation with the 1.125 diameter the thread tool barelly scratches the surface. I guess this is something for the Fusion forum.

Thank you anyway

.

most CNC need to know if you have a sharp vee tool or a tool with a 1/8 flat on tip. that is if thread is .125 apart the flat on the tool tip should be around .0156" width

.

this obviously will effect thread depth when doing the OD threads on a screw. and CAM needs to know how to set the tool tip zero. obviously if you zero to a sharp vee tool tip the pitch diameter will be off. hard to describe but quite obvious when you try to screw a nut on to screw

npolanosky

Cast Iron

- Joined

- Apr 9, 2016

- Location

- USA, FL

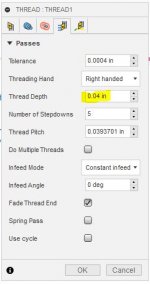

Make sure your Thread Depth is correct in Fusion- It doesn't know anything about the thread you're trying to cut unless you tell it. The thread assigned in the hole tool doesn't talk to threading in CAM. Thread depth will be Major Diameter - Minor Diameter.

Attachments

Larry Dickman

Titanium

- Joined

- Jan 30, 2014

- Location

- Temecula, Ca

it's hard to believe there's 12 responses to a question you just need to look up on a god damn tap chart. 1.115/1.140 for a 2b

DMF_TomB

Diamond

- Joined

- Dec 13, 2008

- Location

- Rochester, NY, USA

it's hard to believe there's 12 responses to a question you just need to look up on a god damn tap chart. 1.115/1.140 for a 2b

.

its not taught now a days cause people use a chart but 8tpi (or .125 thread pitch) thread then screw OD minus thread pitch

.

in metric M6-1.0 so 6-1=5mm tap drill

.

8tpi in inch is .125 thread pitch or space between threads so 1.0-8tpi is .875 tap drill.

Similar threads

- Replies

- 4

- Views

- 431

- Replies

- 8

- Views

- 380

- Replies

- 10

- Views

- 559