rivett608

Diamond

- Joined

- Oct 25, 2002

- Location

- Kansas City, Mo.

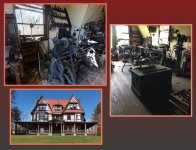

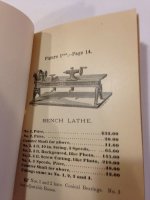

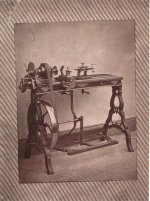

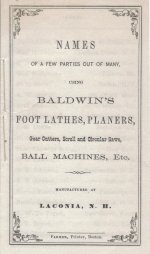

The restoration or cleaning of the 1870 Baldwin/Shultz Lathe is mostly done, it just needs belts replaced and the tooling that goes with it cleaned. I call this an 1870 Baldwin/Shultz Lathe because it was made by Nathan H. Baldwin of Laconia, NH. about 1870. It was owned by Charles S. Shultz (1839-1924) a bank President living in Montclair, NJ. since new and stayed in the family and in his attic workshop until 2021. Simply put this was one of the highest quality, most complex and highly decorated American metal lathes produced in the years following the Civil War. I am basically the only the second owner, however it did pass through two antique dealers/pickers on its way to me. I am certain this machine was hardly used and is almost certainly in the best state of preservation of any known examples. It retains 98% of its original paint and decoration.

I started the restoration with the help of a number of professional museum conservators with the goal to keep and preserve the lathes original finish instead of redoing it like so many early machines. At this point I should just call it a cleaning as that is really about the extent of all I did. Over a 100 hours with solvents and small brushes. It was amazingly complete, I think I only had to make 2 replacement screws, a tribute to the guys that took this apart and down 3 flights of steps. They did an amazing job of keeping it all together. Thank you.

Its current home is in my living behind my desk, some people may question this but our home has been called "The most elegant technical man cave", there are lathes on all 3 floors.

If you have not been following this on my IG or FB you can go back through the past weeks posts for lots of details. Also thank you to the thousands of people following this project and your comments.

I started the restoration with the help of a number of professional museum conservators with the goal to keep and preserve the lathes original finish instead of redoing it like so many early machines. At this point I should just call it a cleaning as that is really about the extent of all I did. Over a 100 hours with solvents and small brushes. It was amazingly complete, I think I only had to make 2 replacement screws, a tribute to the guys that took this apart and down 3 flights of steps. They did an amazing job of keeping it all together. Thank you.

Its current home is in my living behind my desk, some people may question this but our home has been called "The most elegant technical man cave", there are lathes on all 3 floors.

If you have not been following this on my IG or FB you can go back through the past weeks posts for lots of details. Also thank you to the thousands of people following this project and your comments.

Last edited: