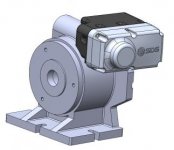

I picked up this 8" rotary that was missing a number of parts for 90 bucks! The missing parts are probably the reason it was so cheap. It appears to be in decent mechanical condition, there is less than .0005 lash in the main bearings and it feels smooth. The worm and main gear appear to be made from hardened steel and wear is nearly undetectable to my eyes, just a very small polished patch in the main gear.

I have a 400w servo lying around I'm going to make brackets for, and it looks like it would all workout pretty well. The castings on this appear to be properly rigid and I think it will work quite well for my needs. I own a business doing engineering, design, and prototyping and most of my cnc work will be one offs to low volume work. With my light duty requirements, and low hours of annual usage, this thing should last a long time unless I screw something up.

Now for my questions I hope someone can help with.

1. Does anyone have any technical manuals for this table or similar one?

2. Oil/ grease. I've seen a number of threads on this for other Nikken tables and it sounds like they use oil or grease, and I saw where one company was advising using a moly lube + being able to reduce the worm lash. Mine seemed to have grease on the main gear and worm, but oil has been found in some of the crevices during disassembly.

3. Main bearing/ seal. MY motion feels good, and there is a grease port (or oil?) for these bearings. Any reason I should crack this part open and clean? I'm thinking to just let it ride, but I'm a little worried about coolant getting in if there is a seal that doesn't exist or needs replacing.

I have a 400w servo lying around I'm going to make brackets for, and it looks like it would all workout pretty well. The castings on this appear to be properly rigid and I think it will work quite well for my needs. I own a business doing engineering, design, and prototyping and most of my cnc work will be one offs to low volume work. With my light duty requirements, and low hours of annual usage, this thing should last a long time unless I screw something up.

Now for my questions I hope someone can help with.

1. Does anyone have any technical manuals for this table or similar one?

2. Oil/ grease. I've seen a number of threads on this for other Nikken tables and it sounds like they use oil or grease, and I saw where one company was advising using a moly lube + being able to reduce the worm lash. Mine seemed to have grease on the main gear and worm, but oil has been found in some of the crevices during disassembly.

3. Main bearing/ seal. MY motion feels good, and there is a grease port (or oil?) for these bearings. Any reason I should crack this part open and clean? I'm thinking to just let it ride, but I'm a little worried about coolant getting in if there is a seal that doesn't exist or needs replacing.