I have a horizontal boring mill that apparently has a 2 speed spindle drive motor. Approximately 8 hp, 240V 3 phase. German built mill and motor. There is a massive switch block in the control box that was used for changing the speed, what exactly is this switch doing? It does not work now as the end that drives the switch shaft is missing so the switch does not couple with the knob on the control box cover. Don’t know if that is by accident or if the low speed gave trouble for some reason so got disabled. Per the label on the control box cover, the slow speed was needed for threading.

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2 speed 3 phase motor?

- Thread starter Gearclash

- Start date

- Replies 18

- Views 1,084

SeikiCorp

Cast Iron

- Joined

- Jun 9, 2022

- Location

- Phoenix, Arizona

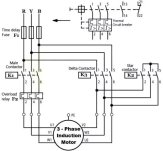

If the 2 speeds are half / double speeds, It might be a wye-delta switch gear.

Very common on modern CNC spindles.

It switches over the motor windings for a 'electrical' 2-speed gearbox of sorts.

Very common on modern CNC spindles.

It switches over the motor windings for a 'electrical' 2-speed gearbox of sorts.

Phil in Montana

Stainless

- Joined

- Jul 31, 2007

- Location

- Missoula Mt

Make it run in high and add a vfd, if the switch is bad you are had...Phil

bloomautomatic

Cast Iron

- Joined

- Oct 17, 2012

- Location

- Pennsylvania

If its just the shaft that connects it, make another one.

You could probably figure a way to manually switch it with a wrench or something (WITH THE POWER SHUT OFF TO THE CABINET) and see how it runs in both speeds. Might have a bad winding in one of the speeds or a bad contact tip in the switch.

Or as others said VFD.

You could probably figure a way to manually switch it with a wrench or something (WITH THE POWER SHUT OFF TO THE CABINET) and see how it runs in both speeds. Might have a bad winding in one of the speeds or a bad contact tip in the switch.

Or as others said VFD.

Peter from Holland

Diamond

- Joined

- Jan 15, 2005

- Location

- The Netherlands

How many positions does that switch has

It could be 3 5 or 7

You could also ad some contactors

3 or 4 would do Depending on the kind of 2 speed motor.Dahlander or 2 seperate windings

It could be 3 5 or 7

You could also ad some contactors

3 or 4 would do Depending on the kind of 2 speed motor.Dahlander or 2 seperate windings

Last edited:

jim rozen

Diamond

- Joined

- Feb 26, 2004

- Location

- peekskill, NY

Photo of the motor nameplate would help clear things up.

The forum does not seem to reduce the pixel count as it apparently used to. The iphone takes a BIG picture, so that may account for your issue.

If you can send it to your PC, you can use a photo program to reduce the pixel count. Every PC up thru win 10 can do that.

There may likely be an app for the phone to do that as well.

If you can send it to your PC, you can use a photo program to reduce the pixel count. Every PC up thru win 10 can do that.

There may likely be an app for the phone to do that as well.

SeikiCorp

Cast Iron

- Joined

- Jun 9, 2022

- Location

- Phoenix, Arizona

cyanidekid

Titanium

- Joined

- Jun 4, 2016

- Location

- Brooklyn NYC

I email the photo to myself and when it asks what resolution to send it, I select medium. this compresses it nicely, then I download from the email, and then I go to recents on my Mac. when in the "select file" box on PM.See if I can get a picture loaded . . .

No luck. Forum software says the file is too large . . . photo is on an IPhone, trying to load via the iPhone . . . what’s the solution?

it sounds slightly complicated, but its actually super easy.

jim rozen

Diamond

- Joined

- Feb 26, 2004

- Location

- peekskill, NY

This may be a consequent pole motor, not star/delta. Suggest the resistances between all wires be measured and listed in a table. Consequent pole motors have the winding topology in a ring, with the connections equally spaced at six locations on the ring. It will show three distinct resistances. Another tip-off it might be consequent pole configuration is if in one speed range, the switchgear shorts three of the windings together.

Check the switch.

Check the switch.

Peter from Holland

Diamond

- Joined

- Jan 15, 2005

- Location

- The Netherlands

Or a motor with 2 seperate windings Nothing on the nameplate Thats wierd

Peter

Peter

jim rozen

Diamond

- Joined

- Feb 26, 2004

- Location

- peekskill, NY

The mystery will be resolved when the 'massive switch block' is decoded....

Switch pictures. The longer switch block is the speed switch. It is a 6 pole switch. The shorter block is the main power switch. I flipped the 2 speed switch to slow with a wrench, turned the main power on, hit the spindle forward button — and the motor spun right up. No whimpers. No magic smoke signals. Why the switch is disconnected from the cover knob is a mystery. My guess is some previous manager didn’t want the trained baboons running the mill to be able to accidentally switch the motor to slow.

john.k

Diamond

- Joined

- Dec 21, 2012

- Location

- Brisbane Qld Australia

Setup is quite common.....black plastic lever on the door ,meshes with the square when door is closed........generally an interlock so the door wont open unless the lever is in the off position.........a modicum of common sense would indicate the squares should correspond when the door is closed,unfortunately common sense is "not common' and the plastic is busted.

jim rozen

Diamond

- Joined

- Feb 26, 2004

- Location

- peekskill, NY

Six pole switch argues for two separate windings but cannot be sure about it unless the truth table is decoded for the leads. Again, settings where three of the leads are shorted to each other and isolated from anything else says consequent pole.

Similar threads

- Replies

- 10

- Views

- 510

- Replies

- 2

- Views

- 155

- Replies

- 11

- Views

- 441

- Replies

- 5

- Views

- 351