General cleaning of the parts I took home is underway, the head unit is the square design, believe the machine is a 1966 model but has the W20 nose, look sin decent shape, has some paint applied at some stage, fair job and perfectly fine for me, cleans up well enough.

Cover plate on the horizontal head unit snapped, made from a plastic which has become a little brittle, will trace and make one from some FR4 sheet I have to match.

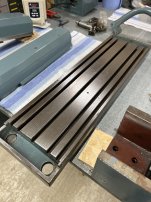

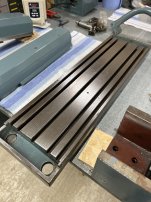

Considering getting the table machined up to clean the surfaces and sides, the surface has one small drill hole but other than that fairly clean, is getting this done a big NO or is it fine to do, will use a friends CNC mill and surface grinder but the finish looks like its been done on a shaper which I do not have access to - pointers/thoughts?

Couple of questions:

In #20 of this thread on the side of the F3 there is the head travel wheel but attached and swinging behind it is a long rod with a black knob on the end - what does this do?

Oils, On my Schaublin 135 lathe I use Mobil Vactra No2 as a way oil and Mobil Velocite No6 as the gearbox oil, would this be a workable/suitableoption for the F3?

Couple of pictures of parts after a little TLC, more to go.

Cover plate on the horizontal head unit snapped, made from a plastic which has become a little brittle, will trace and make one from some FR4 sheet I have to match.

Considering getting the table machined up to clean the surfaces and sides, the surface has one small drill hole but other than that fairly clean, is getting this done a big NO or is it fine to do, will use a friends CNC mill and surface grinder but the finish looks like its been done on a shaper which I do not have access to - pointers/thoughts?

Couple of questions:

In #20 of this thread on the side of the F3 there is the head travel wheel but attached and swinging behind it is a long rod with a black knob on the end - what does this do?

Oils, On my Schaublin 135 lathe I use Mobil Vactra No2 as a way oil and Mobil Velocite No6 as the gearbox oil, would this be a workable/suitableoption for the F3?

Couple of pictures of parts after a little TLC, more to go.