I have linked a document (Trailer_Design_PDF.pdf) going over the design and function of a suspension the allows the trailer frame to move up and down with the help of airbags. Technically known as: "MODULAR DYNAMICALLY ADJUSTABLE SUSPENSION SYSTEM FOR TRAILER." Essentially a trailer that has the ability to change frame height.

However, "The following is a simplified summary of the invention in order to provide a basic understanding of some of the aspects of the invention. This summary is not intended to identify key or critical elements of the invention or to define the scope of the invention."

I have 2 5200 lbs drop axles, with a frame that is approx 17 feet tall and 6.5 feet wide. The trailer needs to be widened. The axles are as long as legally possible around 120-122 inches or so.

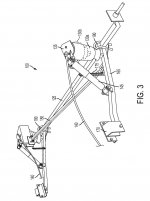

Below are a few pictures showing the basic design. Of course, i welcome criticism, comments, and recommendations on this design. Will it be strong enough to carry a 4500 pound load of wooden pallets? a 6k pound forklift? etc. What are the weak points? what can be changed to get around such frailty?

What really stands out to me are the parts with the following numbers.

pan-hard bar (150) = Panhard bar is a device that can be used to locate a solid rear axle under a vehicle. ... During cornering or sideways movements of the vehicle, the bar keeps the axle located laterally under the body. In this case, one or more pan-hard bars are connected on one side of the said trailer frame and traverse the width of the said trailer frame to connect to a Trailing Arms or (squat bar as the author calls it) (165) mounted on an opposite side of said trailer frame, wherein said pan-hard bar serves to locate and center the drop axle.

I think i can buy most parts off the shelf. I just wonder how improvements to this design can be made.

The deck of the trailer (110) can also be raised above the centerline of the trailer's wheels 115. In an embodiment, the trailer wheels 115 are typically 12" to 25" diameter towing wheels depending on the trailer frame requirements. As explained above, in an exemplary embodiment, smaller diameter wheels are used to facilitate lowering the deck of the trailer 110 closer to the ground.

Source: US8840119B2 - Modular dynamically adjustable suspension system for trailers

- Google Patents

However, "The following is a simplified summary of the invention in order to provide a basic understanding of some of the aspects of the invention. This summary is not intended to identify key or critical elements of the invention or to define the scope of the invention."

I have 2 5200 lbs drop axles, with a frame that is approx 17 feet tall and 6.5 feet wide. The trailer needs to be widened. The axles are as long as legally possible around 120-122 inches or so.

Below are a few pictures showing the basic design. Of course, i welcome criticism, comments, and recommendations on this design. Will it be strong enough to carry a 4500 pound load of wooden pallets? a 6k pound forklift? etc. What are the weak points? what can be changed to get around such frailty?

What really stands out to me are the parts with the following numbers.

pan-hard bar (150) = Panhard bar is a device that can be used to locate a solid rear axle under a vehicle. ... During cornering or sideways movements of the vehicle, the bar keeps the axle located laterally under the body. In this case, one or more pan-hard bars are connected on one side of the said trailer frame and traverse the width of the said trailer frame to connect to a Trailing Arms or (squat bar as the author calls it) (165) mounted on an opposite side of said trailer frame, wherein said pan-hard bar serves to locate and center the drop axle.

I think i can buy most parts off the shelf. I just wonder how improvements to this design can be made.

The deck of the trailer (110) can also be raised above the centerline of the trailer's wheels 115. In an embodiment, the trailer wheels 115 are typically 12" to 25" diameter towing wheels depending on the trailer frame requirements. As explained above, in an exemplary embodiment, smaller diameter wheels are used to facilitate lowering the deck of the trailer 110 closer to the ground.

Source: US8840119B2 - Modular dynamically adjustable suspension system for trailers

- Google Patents