memphisjed

Titanium

- Joined

- Jan 21, 2019

- Location

- Memphis

Maybe braze the nick, brazing adds a little class to the repair.It's steel. Just flush with water and tack weld the nick.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Maybe braze the nick, brazing adds a little class to the repair.It's steel. Just flush with water and tack weld the nick.

I would braze it.It's steel. Just flush with water and tack weld the nick.

^^^this.Split a short piece of rubber fuel line and clamp it in place.

Why? One or two pulls on the trigger of a mig gun and the nick is fixed and likely stronger that the base wall. All heat is very localized and the steel of the tack is actually melted in to the steel of the tubing. To braze, you have to heat a very large section of the tubing and the braze material never actually becomes a part of the tube steel.I would braze it.

plumbing flare tools are not the same!My flaring tool is a plumber’s compression flaring tool… and where I live the auto parts ‘loaners’ are often broken, misadjusted or otherwise unusable! I’ll try APD’s compression union approach because once I have the union I have the tools to install it on hand.

Thanks!

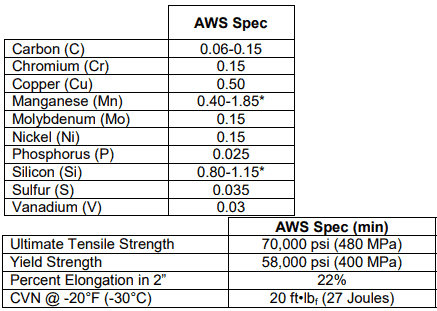

Typical mig wire has a minimum strength of 70,000 psi2001 ranger has 56-72 psi fuel pressure during KOEO test.

Anything short of replacing the line using oem connections is just ....well........

We’re not ALL experts and pros here, and we don’t ALL have all the tools we need… some of us are looking for advice - ADVICE, not criticism - from someone who’s been there/done that… I’m sorry you have the attitude you have but I’m damn sure not the reason for it. I admit to being a fabricobbler - whether you want to admit it or not you weren’t born an expert either!So either buy the proper tools or leave.

"Bend over" yourself wanker,

Interestingly, that’s the ultimate plan… it’s winter in New England, we hafta work in the driveway, and I’m just tryna get the Ranger thru to warm weather… the rubber fuel line has been holding well with just a few exceptions, and I don’t want grandson out tryna tighten clamps at night on a side road so I thought a flare fitting might just be the ticket til spring.plumbing flare tools are not the same!

only use the automotive ones due to pressures and sealing capability of the double flaring tools.

im more surprised that a 2001 ranger still exists and isn't in the crusher. Id probably guess the fuel line is all rusted over and soft all the way down.

better bet is to make a whole new length of it, go to local napa,or wherever and get bulk line and a flaring tool and fuel injection hose clamps. trying to flare old rusty line will keep you running in circles.

Yep. High pressure, high vibration service is no issue for Swagelok. To be clear- these are not the same compression fittings found at Ace Hardware.We use them in critical applications all the time.

I used a ton of Swagelok back in the 80’s… not sure why I didn’t think of them for this application. Prolly cause I live in a small town where the parts folks responded would be “Swage WHAT?” accompanied by a blank stare…Look up "swagelok" fittings... https://www.superloknorthamerica.com/?gclid=EAIaIQobChMI-s29oM3M_AIVFxOtBh159gnaEAAYAiAAEgKuJvD_BwE

They make "everything" so dig in the catalog for the 8mm joiners.

We use them in critical applications all the time.

Southwestern VT… I’ll look online.Get an Ermeto or some times called a "Bite" type compression fitting coupler. Use for hydraulic fittings 3k psi and will not leak or vibrate loose. A hydraulic hose shop or any one doing hydraulic work should have some.

Look on line you should find plenty. Where are you? I have plenty of them at work.

Scrapyards are scarce - and 2001 4-cyl 5-spd Rangers even more so…RockAuto doesn’t sell this line…What about calling the scrapyard/carbreaker or looking on Rockauto?

So, when did Practical Machinist become Critical Machinist? I missed that post, I guess… never said it was either a perfect solution OR a permanent one - just tryna hold things together until we can tear into it properly. Which means warm enough to put the truck up on jack stands in driveway.Well..........I;m going to keep a watch on social media for a kid getting burned to death from tightening hose clamps on a Ford truck...........really??

Weird family love going on here

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.