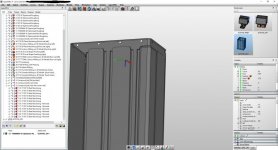

Ok, here is the start of something. The goal of this part would be to have a cube with different features on each side. Each feature would test a different type of toolpath.

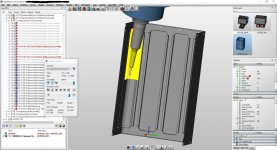

This first side would test Volumetric/Dynamic Roughing toolpath calculations. Obviously, each CAM system will have different parameters, so we will need to figure out how to best setup these parameters so that each system can be spec'd to be the same.

Tool:

0.2500 x 1.250LOC 4FL Endmill 2.500 OAL (no holder)

Stock:

Bounding box of model. No excess.

Volumetric/Dynamic/HSM Rough Operation Parameters:

10% Stepover

0.250 Step Down (no intermediate steps)

0.010 Stock to leave in XYZ

5% Minimum tool path radius (percent of tool dia)

1.000 Clearance Plane

Machine from existing stock

Collision Detection ON

0.002 Machining Tolerance/Deviation (facet size, this can be increased to lengthen calc times)

Couldn't post a photo for all my settings(limited to 5). I imagine it will take a bit of discussion to come up with operation parameters that everyone can use. This is just a start.

To post your results, I would say one should get a snippet of All operation parameters, toolpath image, image of calculation time, and computer specs(OS, CPU, GPU, RAM, etc).

Let me know your thoughts. And if you have an idea for another tool path type/geometry addition to the model that is calculation intensive, Post it!

If a baseline can be built, then maybe we can start a Sticky Thread in CAD/CAM with full instructions/files and everyone can share their results.

Sorry if the photos are shite quality, not sure why that is.

View attachment Benchmark.zip