Pete Deal

Titanium

- Joined

- Apr 10, 2007

- Location

- Morgantown, WV

Brother S1000 4th Axis Setup

I bought a new Brother S1000 about a year and a half ago. I got the Brother T200 4th axis with it. When they installed the machine the tech set the 4th up but I removed it from the machine soon after. I didn't have time to get into tooling at that point and figured it would be one less thing in the way till I had the time to mess with it.

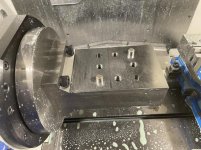

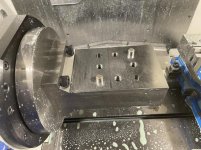

Last week was the time. I never saw anything off the shelf that looked like what I wanted so I ordered some ductile iron from McMaster and made a faceplate and tomb stone. The T200 doesn't come with any faceplate at all. It just has the raw hollow shaft looking at you when you get it. It's tight in Z but workable for my needs. At least I think it is, haven't actually used it yet. To mount the T200 rotary table on the S1000 an adapter plate is required. This adds about 3/4" of unwanted height. Getting rid of this adapter plate is on the list of stuff to do. Also shortening up my Haimer probe will help. The tomb stone as is will allow a vise to be mounted on either side. Also, the vise I ordered has the SMW mounting pattern This allows the vise to be mounted in the two directions shown on a 4" wide tomb stone. I may in the future as needed make it so the tomb stone can be mounted lower on the face plate if I need even more Z.

Getting the dowel pin holes located precisely was a worry. A few years ago I cobbled a 30 taper kaiser boring head setup together off ebay but never used it. It's an EWN2-32. I really didn't know much of anything about these. I learned that getting the boring head is just the start. Man are they proud of the pieces. And although it's supposed to handle holes between 2-32mm by the time you bought the parts for it do do that you'd have a pile of money in the setup. I wound up adapting a 5/16" carbide bar I have to it and man does that thing work nicely! Much better than my past experience with my chicom Criterion copy.

Not shown but I still have enough room for two 6" vises too.

This is my first time at any 4th axis work. Now I've been reading about the center of rotation programming for this control. I found out yesterday that the G54.2 is an option I don't have. So one question I have is how useful is this for 4th axis work? For now it will all be positioning. It seems it would be a very nice option since only one work offset would need to be set on the part. Also it seems like it ought to be much more accurate. It can be added for about $1000 but how helpful is it?

I bought a new Brother S1000 about a year and a half ago. I got the Brother T200 4th axis with it. When they installed the machine the tech set the 4th up but I removed it from the machine soon after. I didn't have time to get into tooling at that point and figured it would be one less thing in the way till I had the time to mess with it.

Last week was the time. I never saw anything off the shelf that looked like what I wanted so I ordered some ductile iron from McMaster and made a faceplate and tomb stone. The T200 doesn't come with any faceplate at all. It just has the raw hollow shaft looking at you when you get it. It's tight in Z but workable for my needs. At least I think it is, haven't actually used it yet. To mount the T200 rotary table on the S1000 an adapter plate is required. This adds about 3/4" of unwanted height. Getting rid of this adapter plate is on the list of stuff to do. Also shortening up my Haimer probe will help. The tomb stone as is will allow a vise to be mounted on either side. Also, the vise I ordered has the SMW mounting pattern This allows the vise to be mounted in the two directions shown on a 4" wide tomb stone. I may in the future as needed make it so the tomb stone can be mounted lower on the face plate if I need even more Z.

Getting the dowel pin holes located precisely was a worry. A few years ago I cobbled a 30 taper kaiser boring head setup together off ebay but never used it. It's an EWN2-32. I really didn't know much of anything about these. I learned that getting the boring head is just the start. Man are they proud of the pieces. And although it's supposed to handle holes between 2-32mm by the time you bought the parts for it do do that you'd have a pile of money in the setup. I wound up adapting a 5/16" carbide bar I have to it and man does that thing work nicely! Much better than my past experience with my chicom Criterion copy.

Not shown but I still have enough room for two 6" vises too.

This is my first time at any 4th axis work. Now I've been reading about the center of rotation programming for this control. I found out yesterday that the G54.2 is an option I don't have. So one question I have is how useful is this for 4th axis work? For now it will all be positioning. It seems it would be a very nice option since only one work offset would need to be set on the part. Also it seems like it ought to be much more accurate. It can be added for about $1000 but how helpful is it?

Last edited: