ssgw

Aluminum

- Joined

- Dec 6, 2014

- Location

- North East Wyoming

wrench

As for the hot load..maybe so. I may never know the whole history. From borescoping the throat, it looks like a few rounds have gone down the tube. The owner provided me with his dies, powder, primers, bullets, all that he used to make the rounds with, as well as new brass. He had the same problem, old and new.

If I changed the action, I was going to reuse the barrel, that is if I can find a definite fault in the action. There just has to be an reason for the issue he is seeing, and I am determined to at least find it, if not fix it.

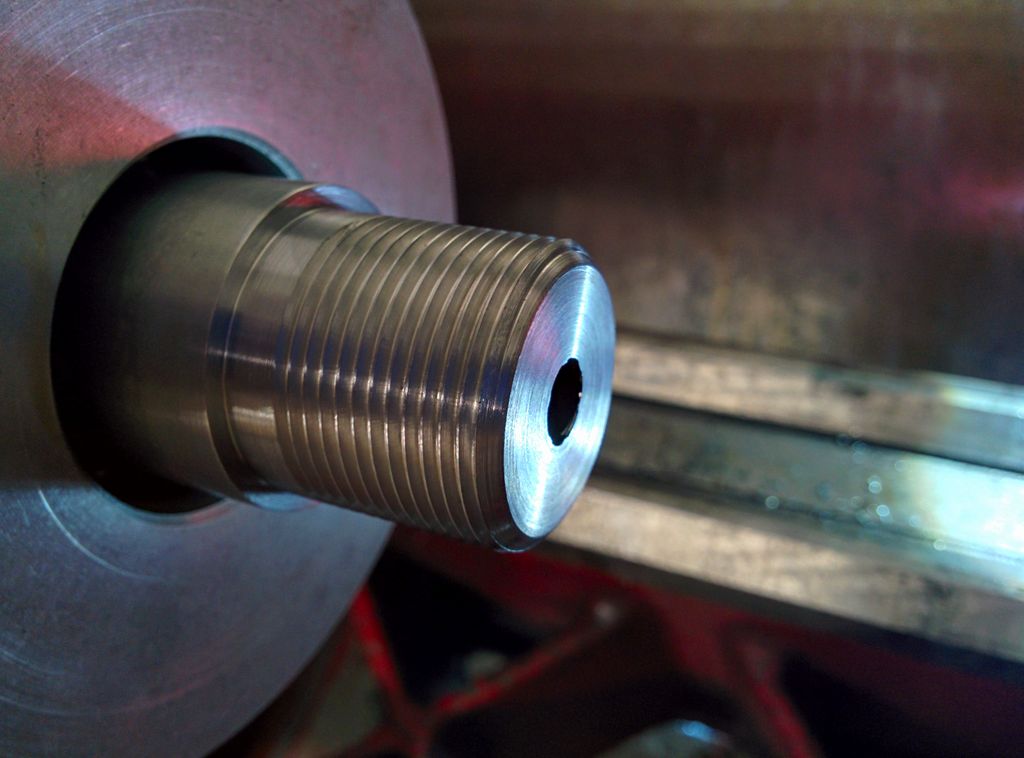

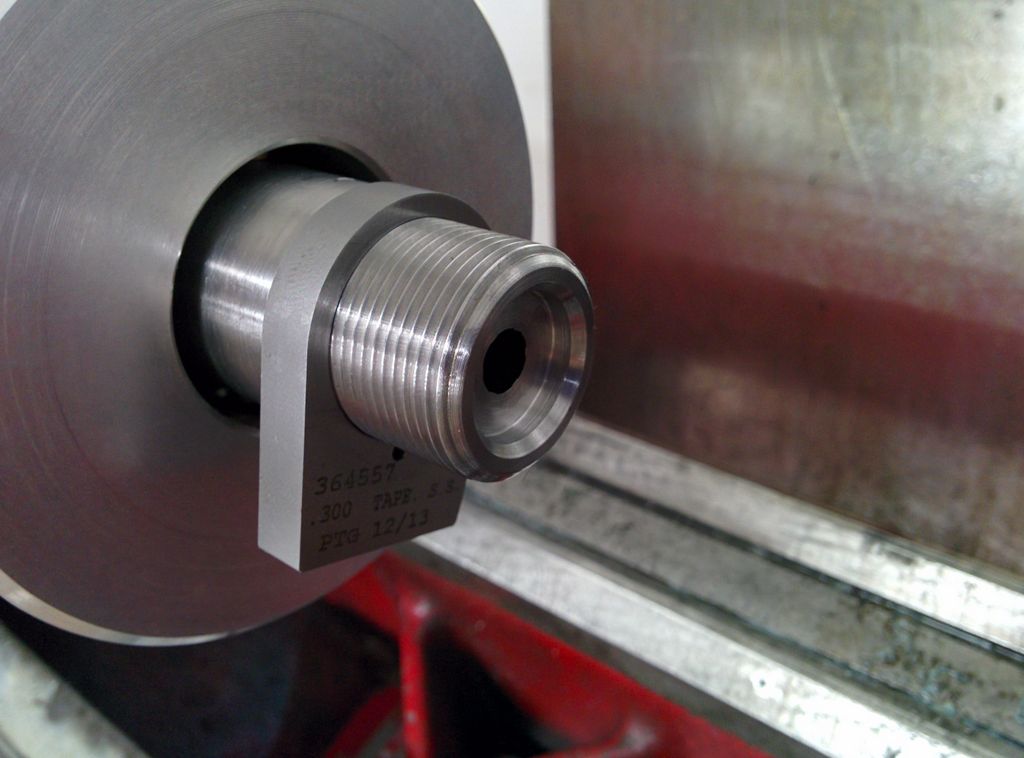

What are your thoughts against using the internal wrench?I'd recommend against using an internal wrench on a stubborn or factory installed 700 barrel.

I have a hunch the lug is just rough because its a new production Remington and not because of a hot load. I also have a hunch the case head separation is over resized brass, and not a problem with the rifle at all.

If you're going to replace the "action", are you planning on reusing the barrel? Realistically, by the time you refit the barrel to the new action, you may as well just completely start from scratch with a new action and new barrel.

As for the hot load..maybe so. I may never know the whole history. From borescoping the throat, it looks like a few rounds have gone down the tube. The owner provided me with his dies, powder, primers, bullets, all that he used to make the rounds with, as well as new brass. He had the same problem, old and new.

If I changed the action, I was going to reuse the barrel, that is if I can find a definite fault in the action. There just has to be an reason for the issue he is seeing, and I am determined to at least find it, if not fix it.

They are all within normal spec's.

They are all within normal spec's.