Crazy are the folks who don't see potential in these fine old machines. I've been wanting to know more about fans and now I know. I love this place

No, crazy are those who take the time to fix them properly, hence why I called this thread "Contest for the MOST INSANE member". For the hours I have spent on my Tree, the MC800H and the Mori SL-6B (Not even including the Daewoo) had I been just working a normal job putting in paying hours I would have been able to easily buy a couple new machines already.

This is why it is important to be very picky about which machines are going to be fixed. If the machine would have a extremely high replacement value like the MC800H (if you tried to spec out a similar machine new) and you have the ability to leverage it's capabilities then it might be worth it, assuming you have the time to soak into without putting yourself in a bind.

The main reason that machine isn't finished is because I have to throttle back my time in so I'm not hurting cash flow by working on it. The Mori SL-6B came from here in Calgary (to answer Aaron) and not only did I get it for a good price but what I make really can benefit from that exact spec of lathe and to get one in excellent condition that can be relied upon for a long time would be quite costly. Not in the realm of the MC800H, but then again it hasn't been the same level of work to go through as the MC800H either.

An update: The last few days I've been focusing on both machines simultaneously, electrical at my home shop and mechanical/paint prep at the bay. Yesterday was mechanical on the Mori and I had been on the fence about leaving the carriage on the machine and just masking and painting that in place... until I moved it:

The lower way has contaminated oil on it and will be cleaned as well as the turcite when the carriage is pulled. Also the X axis cross slide needs cleaning too, so the entire assembly will be coming apart and meticulously cleaned.

I had to drain the gearbox to the Z axis servo and pull the servo so I could turn the ballscrew. This machine has a gearbox to increase the max torque it can put through the ballscrew for greater Z axis force. The DC servo is a very large already so Mori weren't messing around when they designed this machine. It can put heavy force into the part.

I was trying really hard to not completely dismantle this machine to the bare castings but I think it is going to happen anyway. This way I can repaint everything as I like and it'll look very clean like my Tree lathe. At least I don't have to completely go through the hydraulics like I did on the tree, I think anyway. I need to look in the tank and make sure it looks clean. Everything I have drained thus far didn't look contaminated.

I can confirm that this machine is mechanically capable of traveling almost 1000 mm in Z but the chuck eats up a large amount of this travel. If a collet chuck were designed that fit inside the large 6.4" bore of the spindle (Like the Tree has) then I could have the option to gain that travel with the machine if something came up. These are the details that would be hard to know if such an effort hadn't been undertaken. I've increased travels on other machines before and it made the difference between being able to finish the job or not. One time it was very expensive one off job that came down to less than half a mm before the machine hit a mechanical limit. Worked out in my favor that day!!!

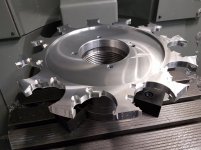

Here is the bad news, the Z axis ball screw has lost preload and has a TON of slop. It'll be coming out and getting rebuilt, I'll probably throw in new angular contact bearings on the ends as well. It is unfortunate to find such wear but not surprising. I may just get the screws rebuilt on all the lathes at the same time just so that doesn't need to be looked at again for many years. Almost all of them are out at the moment. I could get the MC800H's done too but the accuracy of the machine isn't dependent on the screws and they don't have any play right now. Having said this it is a massive pain to get them out so maybe now is a good time. At least crating them would be easier having 9 ball screws in a crate rather than 1 or 2 at a time.

Aaron: You are right about how large the SL-6B is, it is very tall. It is taller than my DMU50V which is a vertical mill! The headstock is absolutely massive and the whole machine just emanates rigidity. Because I am in Oil Country I've seen lathes that make even the Mori look small. My next lathe will have a 10+ bore in it, I hope I can find this same model in the SL-6C variety, though a 7 might work well for my purposes too.

Dave