Hello,

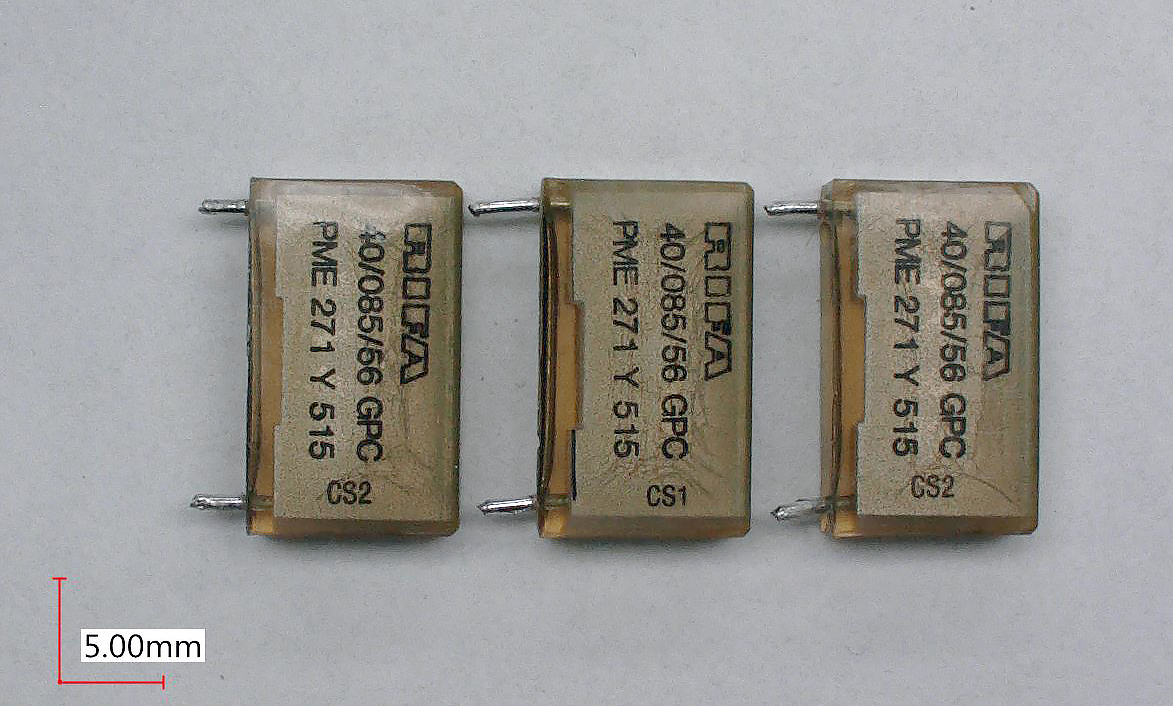

I got a 1987 FP4A with Hurco electronics about a year ago. It's been running great until recently when a few of the caps violently burned up in the last column of the Suppressor Bank Board (415-0118-001A)---I think the last column is connected to the coolant pump, which also stopped working at the same time.

I replaced the board, but when I turned on the machine (with the coolant pump off) the same few caps slowly started to heat up from 56F to 65F while the others stayed at 56F. The 65F wasn't the problem, but the trend and pattern of the heating was concerning. I stopped at this point and now I'm looking for some info and advice on how to proceed. In particular:

Istvan

I got a 1987 FP4A with Hurco electronics about a year ago. It's been running great until recently when a few of the caps violently burned up in the last column of the Suppressor Bank Board (415-0118-001A)---I think the last column is connected to the coolant pump, which also stopped working at the same time.

I replaced the board, but when I turned on the machine (with the coolant pump off) the same few caps slowly started to heat up from 56F to 65F while the others stayed at 56F. The 65F wasn't the problem, but the trend and pattern of the heating was concerning. I stopped at this point and now I'm looking for some info and advice on how to proceed. In particular:

- What does the board do?

- Were these just aging caps or a faulty coolant pump (or other component) could cause the caps to fail?

Istvan