richard newman

Titanium

- Joined

- Jul 28, 2006

- Location

- rochester, ny

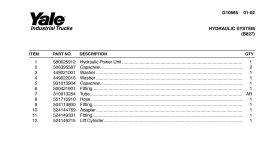

My Yale MPB040E pallet jack drops WAY too fast with a load, bam!!! What could cause this? Fluid was low when I got it, topped it up, no change. Now I'm curious what actually determine the lowering speed, some sort of flow restrictor? Attaching parts diagram.

edit- changed pdf to jpeg

edit- changed pdf to jpeg