angelw

Diamond

- Joined

- Sep 10, 2010

- Location

- Victoria Australia

I see in your iteration above, you have dropped the S1500M03 from the code example in your earlier Post. The Rigid Tapping Cycle should be allowed to start the spindle; my Fanuc colleagues have mentioned numerous times that having the spindle running before initiating Rigid Tapping can cause unusual results.Ok so this code does actually run and make very nice threads, but remove the M5 and no go. And If I substitute M95 for the M5 I'm sure it would work as well but I haven't tried it. Thanks everyone for trying to help, much appreciated!!

And to answer your question Dan. M95 on this machine is Spindle Stop and Coolant Off.

N4G17G80G40G90G49G0

T4M06 ( #2-56 CUT TAP )

G90G54

G90G0X2.805Y-.0075

G43Z.1H4

M08

M84S1500

G84G98X2.805Y-.0075Z-.34R.1F26.78571

X2.055

X1.59

X.84

X.375

X-.375

X-.84

X-1.59

X-2.055

X-2.805

G80M5

G0Z.1

M09

G91G28Z0.

G0G90G53X0.Y0.

M30

Did you introduce G80 M5 at the same time you dropped the S1500M03 from your program? If so, it may be the omission of the S1500 M03 that now makes your program work; does the program still halt if you omit M5 from the block containing the G80 and with the S1500 M03 omitted from your program?

The way you have your program configured with the following:

M84S1500

G84G98X2.805Y-.0075Z-.34R.1F26.78571

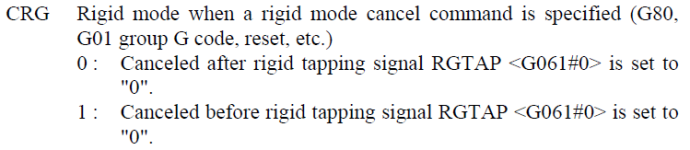

you would have to have parameter 5200.0 set to "0" and "84" registered in parameter 5210 (specifies the "M" code to start Rigid Tapping).

Automatic Teller Machines go by the acronym ATM and the quick Covid Test, the Rapid Antigen Tests by the acronym RAT. Many people call these respectively ATM Machines and RAT Tests, which translates to Automatic Teller Machines Machines and Rapid Antigen Test Tests. It's somewhat similar when M84 is used as the "M" Code to initiate Rigid Tapping.

As mentioned by Sinha, by setting parameter bit 5200.0 to "1", Rigid Tapping is initiated with G84 and without the requirement of an "M" code. However, this then doesn't allow the use of conventional tapping, should, for some reason, you may want to use it.

By setting parameter 5200 to "1", the "M" code can be omitted and Rigid Tapping will be initiated by G84; the "S" code can be specified in the G84 Block. If parameter 5200 is set to "0" and parameter 5210 also set to "0", the default "M" code M29 is judged to be have been set.

What is parameter bit 5200.2 set to? If set to "0", try setting it to "1".

Any Group 1 G Code will also cancel a Canned Cycle, such as G84. Although G80 should work (and it may be the setting of parameter bit 5200.2 that is upsetting it), try dropping the G80 M5 from the extract from your code below:

G80M5

G0Z.1

and just have G0 Z0.1, it should have the same affect as G80.

Regards,

Bill

Last edited: