Zip

Aluminum

- Joined

- May 25, 2007

- Location

- Champlain, NY

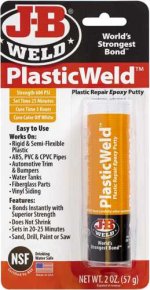

What can be used to fill any cavities between a scope base and firearm mounting surface. (anodized base/SS frame)

It has to be something hard when cured, can be worked before it sets and later allow the base to be removed if necessary

Thanks

It has to be something hard when cured, can be worked before it sets and later allow the base to be removed if necessary

Thanks