Brian Campbell

Plastic

- Joined

- Dec 14, 2021

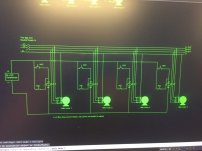

I am building a rotary phase converter using four smaller (2.3kw) wye motors to convert the two legs and neutral I have coming into the property into three legs and a neutral.

I live in New Zealand, on some rural properties we have two legs and a neutral coming in but are missing the third leg, I am building a rpc to generate the third leg. Our power supply is 230v phase to neutral and 415v between phases.

I need to run a 7.5kw motor on a lathe that has a full current draw of 14a

The question I have is if the rpc has enough capacity to do this using four 2.3kw motors.

The total of the four idler motors in kw is around 9.2kw, looking at it this way it seems undersized.

However, If my math’s is correct the two legs I have coming in will need to provide 21 amps each to supply the motor (3 phases x14amps = 42) (42 amps /2 phases =21 amps)

If I look at the full load amperage of all four motors combined, it is around 23amps. i.e the four motors can handle the amp draw needed by the big lathe motor.

What I’m unsure of is how the lower efficiency of using smaller motors comes into this, the motors can handle the amps, but does this translate to being able to provide the larger lathe motor with what it needs?

I live in New Zealand, on some rural properties we have two legs and a neutral coming in but are missing the third leg, I am building a rpc to generate the third leg. Our power supply is 230v phase to neutral and 415v between phases.

I need to run a 7.5kw motor on a lathe that has a full current draw of 14a

The question I have is if the rpc has enough capacity to do this using four 2.3kw motors.

The total of the four idler motors in kw is around 9.2kw, looking at it this way it seems undersized.

However, If my math’s is correct the two legs I have coming in will need to provide 21 amps each to supply the motor (3 phases x14amps = 42) (42 amps /2 phases =21 amps)

If I look at the full load amperage of all four motors combined, it is around 23amps. i.e the four motors can handle the amp draw needed by the big lathe motor.

What I’m unsure of is how the lower efficiency of using smaller motors comes into this, the motors can handle the amps, but does this translate to being able to provide the larger lathe motor with what it needs?