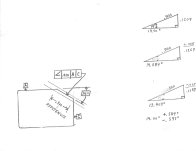

I have an angular check on a part that is hard to fixture. I am trying to see if it is possible to use trig to satisfy the Angular band on a part. ( Checking part with optical imaging that does not have Angular GD&T capabilities. ) Attached hand sketch is a simple illustration to see if my logic will satisfy the .010” Angular band tolerance.

Angle is 14 degrees, length of angle is .500”. Angular callout is .010”.

At 14 degrees, length of side opposite is .1209”.

If I add .005” to this, the Angle increases to 14.584 degrees.

If I subtract .005” from .1209” the angle decreases to 13.403 degrees.

Can I apply a tolerance of 14.00 degrees +.584/-.597 degrees and fall within the .010” angular bandwidth?

Thanks,

Ron

Angle is 14 degrees, length of angle is .500”. Angular callout is .010”.

At 14 degrees, length of side opposite is .1209”.

If I add .005” to this, the Angle increases to 14.584 degrees.

If I subtract .005” from .1209” the angle decreases to 13.403 degrees.

Can I apply a tolerance of 14.00 degrees +.584/-.597 degrees and fall within the .010” angular bandwidth?

Thanks,

Ron